- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 24, 2025 05:45

Back to list

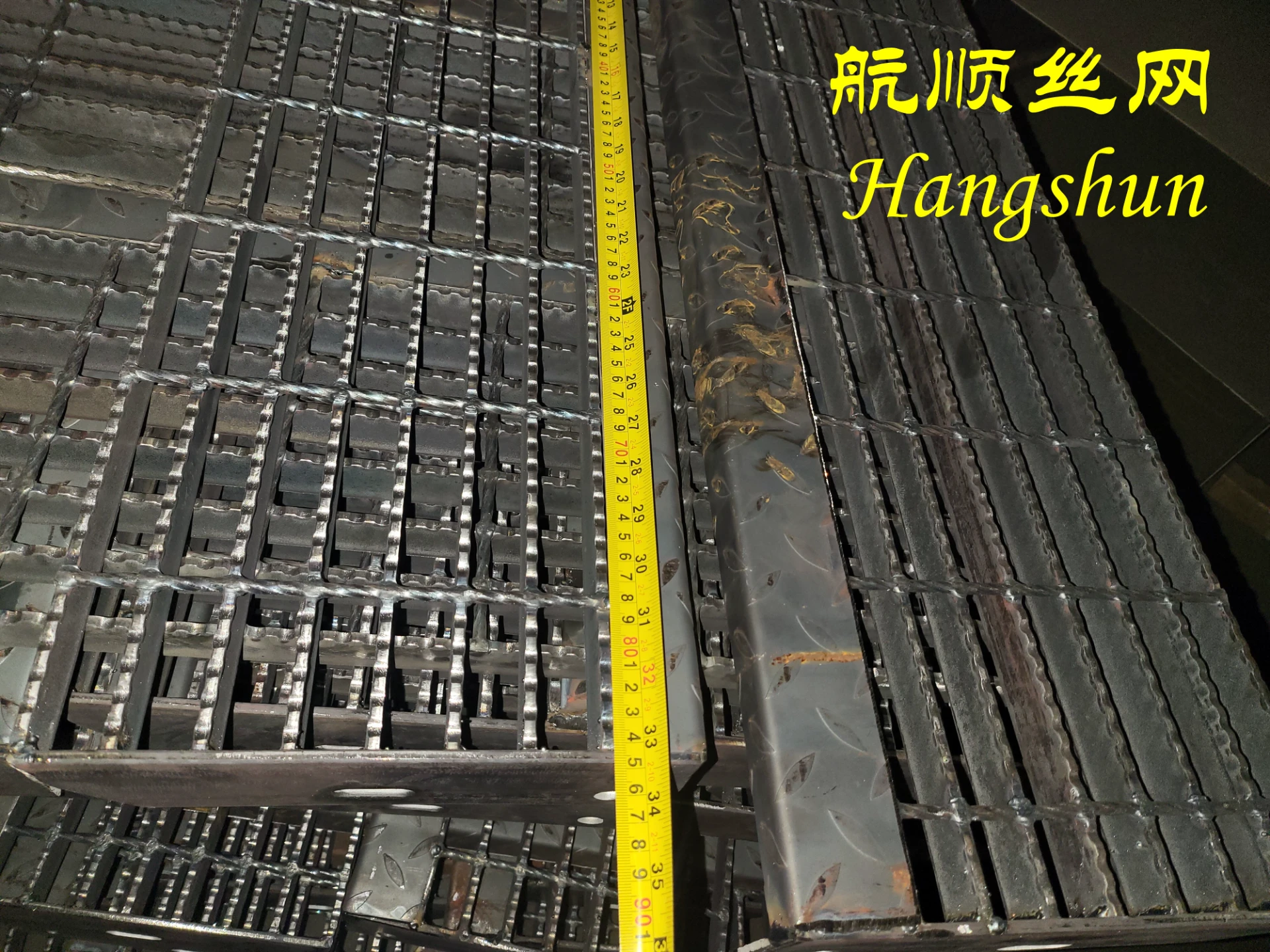

Steel Grating

Grating galvanized steel is a versatile and integral material that is making significant strides in various industrial applications. This product, known for its robustness and durability, offers a range of benefits that far outweigh its initial cost, making it an essential material for industries encompassing construction, infrastructure, and manufacturing. Leveraging the expertise derived from decades of specialized industry work, this article delves into the core attributes, applications, and benefits that make grating galvanized steel a product to reckon with.

In terms of trustworthiness, the use of grating galvanized steel is backed by extensive research and testing. Over the years, rigorous testing has ensured that this material performs well under a variety of stressors—be it mechanical or environmental. The trust that industries place in this material is a testament to its reliability. Manufacturers of galvanized steel grating comply with international engineering standards, further guaranteeing that each piece is designed to perform optimally. Understanding the broader applications of galvanized steel grating further emphasizes its place in modern industry. From pedestrian bridges to platforms in volatile chemical plants, its role cannot be understated. The open grid gives workers a sturdy but visible path, which is crucial in environments where soon-to-be-serviced equipment lies underneath. In essence, it unites structural integrity with utility. The economic aspect also plays a role in the rising popularity of grating galvanized steel. As the global economy continues to adapt and industries seek sustainable growth measures, the balance of initial investment versus the ongoing benefits of galvanized steel becomes increasingly attractive. The adaptability of this material across various sectors underscores its economic viability, making it a practical choice for businesses aiming at resilience and sustainability. In conclusion, the grating galvanized steel industry is positioned at the intersection of experience, expertise, authoritativeness, and trustworthiness—a quartet vital for informed industrial material selection. As industries evolve, the demand for reliable, cost-effective, and durable materials continues to surge, and galvanized steel grating remains at the forefront, providing solutions that are as practical as they are innovative.

In terms of trustworthiness, the use of grating galvanized steel is backed by extensive research and testing. Over the years, rigorous testing has ensured that this material performs well under a variety of stressors—be it mechanical or environmental. The trust that industries place in this material is a testament to its reliability. Manufacturers of galvanized steel grating comply with international engineering standards, further guaranteeing that each piece is designed to perform optimally. Understanding the broader applications of galvanized steel grating further emphasizes its place in modern industry. From pedestrian bridges to platforms in volatile chemical plants, its role cannot be understated. The open grid gives workers a sturdy but visible path, which is crucial in environments where soon-to-be-serviced equipment lies underneath. In essence, it unites structural integrity with utility. The economic aspect also plays a role in the rising popularity of grating galvanized steel. As the global economy continues to adapt and industries seek sustainable growth measures, the balance of initial investment versus the ongoing benefits of galvanized steel becomes increasingly attractive. The adaptability of this material across various sectors underscores its economic viability, making it a practical choice for businesses aiming at resilience and sustainability. In conclusion, the grating galvanized steel industry is positioned at the intersection of experience, expertise, authoritativeness, and trustworthiness—a quartet vital for informed industrial material selection. As industries evolve, the demand for reliable, cost-effective, and durable materials continues to surge, and galvanized steel grating remains at the forefront, providing solutions that are as practical as they are innovative.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024