- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 25, 2025 00:33

Back to list

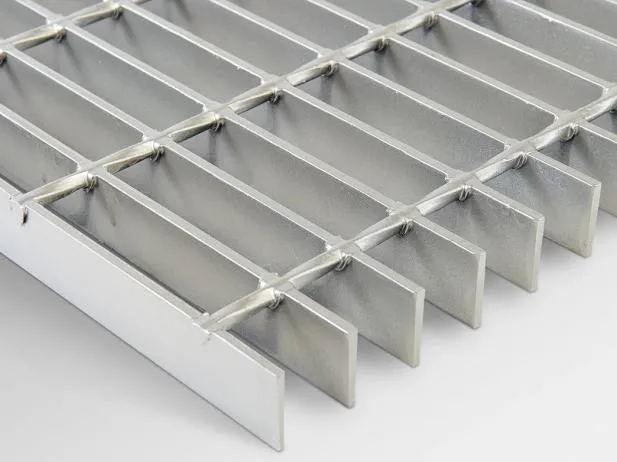

grating hot dip galvanized

The industrial and construction sectors have long been acquainted with the resilience and reliability of hot-dip galvanized grating. As a protective measure, this process involves coating steel or iron with a layer of zinc, thus providing an unparalleled level of resistance against corrosion. But beyond its technical allure, what makes hot-dip galvanized grating an optimal choice for project managers and engineers across various industries?

Trust in this grating solution is often a byproduct of its proven track record. Real-world installations have shown that hot-dip galvanized grating can surpass the 50-year mark in terms of effective service life, fostering trust among stakeholders. This is particularly significant in sectors where safety and structural integrity are paramount. Regular inspections of such installations reveal that even after decades of exposure to the elements, hot-dip galvanized grating typically shows minimal degradation, a testament to its enduring robustness. The environmental benefits of hot-dip galvanized grating further enhance its trustworthiness. The zinc layer acts as both a protector and sacrificial element—meaning, it corrodes in place of the metal it shields. This sacrificial behavior is a key reason why galvanized steel can survive in the harshest of climates without needing frequent replacement, thereby reducing waste and promoting greener construction practices. These sustainability credentials often align well with corporate goals geared towards reducing environmental footprints. In conclusion, the multifaceted advantages of hot-dip galvanized grating—from exceptional long-term performance and substantial cost savings to its environmental sustainability attributes—make it a compelling choice for diverse engineering needs. Coupled with a history of reliable application and adherence to the highest standards, it stands as a stalwart component in modern construction and industrial processes. This knowledge-driven choice not only meets immediate project demands but also aligns with strategic visions for durability and sustainability, rendering hot-dip galvanized grating an unparalleled asset in forward-thinking engineering projects.

Trust in this grating solution is often a byproduct of its proven track record. Real-world installations have shown that hot-dip galvanized grating can surpass the 50-year mark in terms of effective service life, fostering trust among stakeholders. This is particularly significant in sectors where safety and structural integrity are paramount. Regular inspections of such installations reveal that even after decades of exposure to the elements, hot-dip galvanized grating typically shows minimal degradation, a testament to its enduring robustness. The environmental benefits of hot-dip galvanized grating further enhance its trustworthiness. The zinc layer acts as both a protector and sacrificial element—meaning, it corrodes in place of the metal it shields. This sacrificial behavior is a key reason why galvanized steel can survive in the harshest of climates without needing frequent replacement, thereby reducing waste and promoting greener construction practices. These sustainability credentials often align well with corporate goals geared towards reducing environmental footprints. In conclusion, the multifaceted advantages of hot-dip galvanized grating—from exceptional long-term performance and substantial cost savings to its environmental sustainability attributes—make it a compelling choice for diverse engineering needs. Coupled with a history of reliable application and adherence to the highest standards, it stands as a stalwart component in modern construction and industrial processes. This knowledge-driven choice not only meets immediate project demands but also aligns with strategic visions for durability and sustainability, rendering hot-dip galvanized grating an unparalleled asset in forward-thinking engineering projects.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024