- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 24, 2025 04:13

Back to list

Rope Perimeter Safety Netting

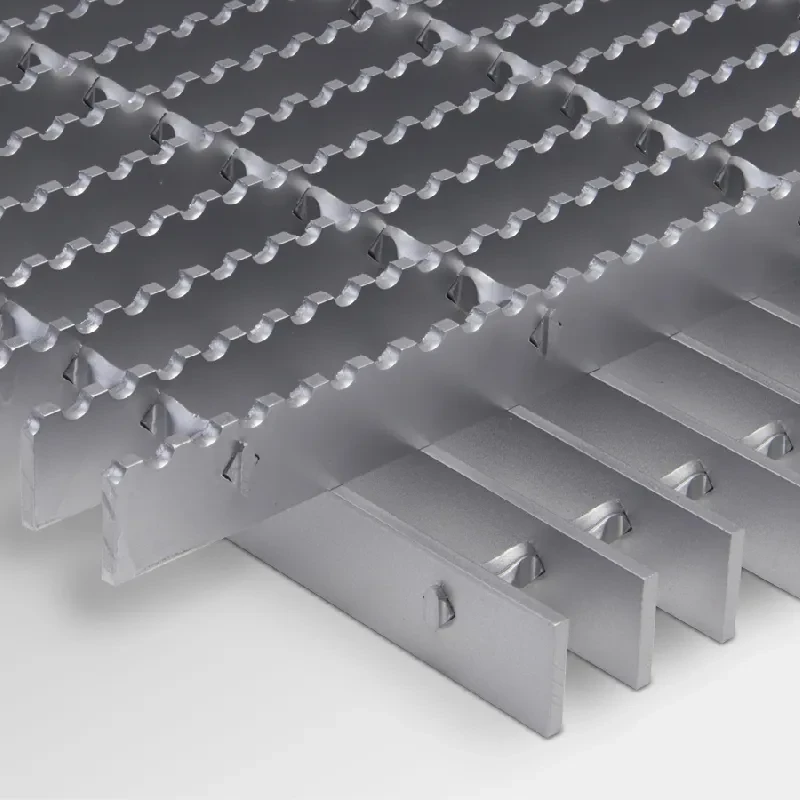

Galvanized steel grids have long been recognized as the backbone of many construction and industrial projects due to their robust nature and enduring quality. These grids, often referred to as steel grates or steel mesh, are commonly used in a plethora of applications ranging from flooring and walkways to drainage covers and fencing. Their versatility and durability make them an indispensable asset in the construction industry.

In the realm of security, galvanized steel grids provide an added layer of protection. Structures such as security fences, barriers, and gates gain substantial reinforcement from the use of these grids. The difficulty in tampering or cutting through galvanized steel without specialized equipment enhances the security of premises, vital for sensitive installations such as airports, military bases, and industrial sites. Furthermore, the visibility provided by the open grid pattern allows for effective monitoring, deterring potential intruders. Despite their utility and advantages, selecting the appropriate type of galvanized steel grid for a specific application requires a degree of expertise. Factors such as load-bearing requirements, environmental conditions, and budget constraints must be meticulously considered. Collaborating with experts in metallurgy or structural engineering can provide invaluable insights, ensuring the selected grid meets the demands of the intended project. For industries such as mining, oil and gas, and heavy manufacturing, the reliance on galvanized steel grids extends beyond simple functionality. These sectors demand materials that can withstand extreme pressures, high temperatures, and corrosive agents. In such cases, the customization of grid thickness, mesh size, and the galvanization thickness is often undertaken to meet industry-specific certification standards, ensuring that safety and operational efficiency are consistently maintained. In conclusion, galvanized steel grids remain a pivotal component within the construction and industrial sectors. Their proven track record in durability, cost-efficiency, and adaptability makes them a preferred choice among engineers and architects alike. As technology advances and sustainable practices continue to evolve, the role of galvanized steel grids is likely to expand, promising innovations that leverage their strengths while potentially addressing emerging industry challenges. For any project aiming for longevity and reliability, galvanized steel grids present a tried and trusted solution.

In the realm of security, galvanized steel grids provide an added layer of protection. Structures such as security fences, barriers, and gates gain substantial reinforcement from the use of these grids. The difficulty in tampering or cutting through galvanized steel without specialized equipment enhances the security of premises, vital for sensitive installations such as airports, military bases, and industrial sites. Furthermore, the visibility provided by the open grid pattern allows for effective monitoring, deterring potential intruders. Despite their utility and advantages, selecting the appropriate type of galvanized steel grid for a specific application requires a degree of expertise. Factors such as load-bearing requirements, environmental conditions, and budget constraints must be meticulously considered. Collaborating with experts in metallurgy or structural engineering can provide invaluable insights, ensuring the selected grid meets the demands of the intended project. For industries such as mining, oil and gas, and heavy manufacturing, the reliance on galvanized steel grids extends beyond simple functionality. These sectors demand materials that can withstand extreme pressures, high temperatures, and corrosive agents. In such cases, the customization of grid thickness, mesh size, and the galvanization thickness is often undertaken to meet industry-specific certification standards, ensuring that safety and operational efficiency are consistently maintained. In conclusion, galvanized steel grids remain a pivotal component within the construction and industrial sectors. Their proven track record in durability, cost-efficiency, and adaptability makes them a preferred choice among engineers and architects alike. As technology advances and sustainable practices continue to evolve, the role of galvanized steel grids is likely to expand, promising innovations that leverage their strengths while potentially addressing emerging industry challenges. For any project aiming for longevity and reliability, galvanized steel grids present a tried and trusted solution.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024