- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 24, 2025 03:51

Back to list

metal walkways gratings

The diverse applications of galvanised metal grates make them an indispensable component in both industrial and residential settings. Characterized by their corrosion-resistant properties, strength, and durability, these grates are crafted by coating metal, typically steel, with a protective layer of zinc. This innovative process prevents rusting and enhances the longevity of the metal, making it an ideal choice for numerous applications. From drainage systems and walkways to ventilation and security settings, galvanised metal grates play crucial roles, reflecting the creativity and necessity underpinning their use.

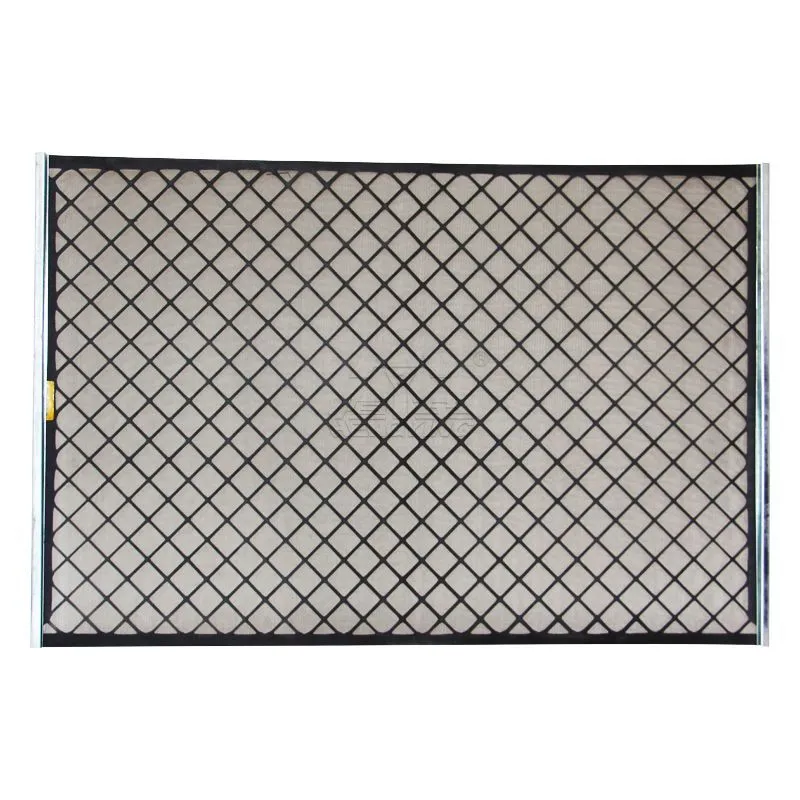

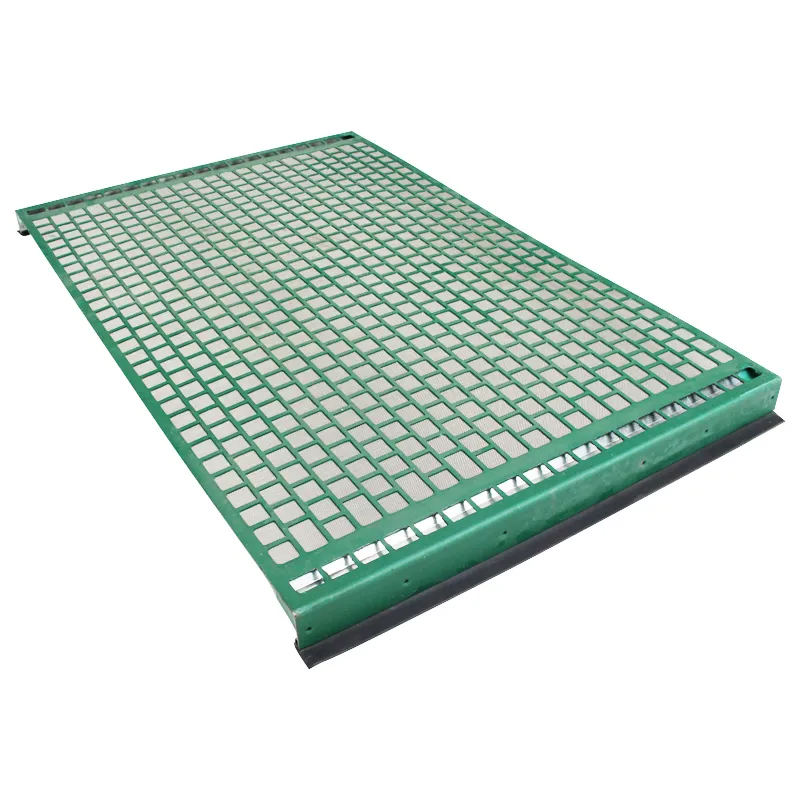

In security applications, galvanised metal grates provide a formidable barrier against unauthorized access. They are often used in windows, doors, and fencing where strength and resilience are crucial. These grates can withstand force while providing a clear line of sight, combining security with transparency - a balance often required in security design. The galvanisation process fortifies them against environmental exposure, ensuring longevity in demanding security environments. This role exemplifies the expertise involved in creating dependable security solutions. Reflecting on real-world experiences, the versatility of galvanised metal grates becomes evident. Homeowners appreciate their utility in garden and landscape projects, where drainage, security, and aesthetic aspects must coexist harmoniously. Industries, on the other hand, test their mettle daily in rigorous settings, from chemical plants to heavy manufacturing units, where their performance directly impacts operational efficiency and safety. Choosing galvanised metal grates requires consideration of the quality of galvanisation; thickness, coating, and method influence their suitability for specific uses. Trustworthy manufacturers ensure compliance with industry standards, thereby enhancing the reliability of these products. Engaging with suppliers who understand the nuanced requirements of different applications is crucial in selecting the right product. In conclusion, the diverse applications of galvanised metal grates span from industrial safety solutions to architectural elegance, underscoring their indispensable role in various sectors. Their corrosion resistance, strength, and durability speak to the expert craftsmanship involved in their creation. As infrastructure continually evolves, the need for reliable, authoritative solutions like galvanised metal grates persists, highlighting their continued relevance in meeting the multifaceted demands of modern industry and society.

In security applications, galvanised metal grates provide a formidable barrier against unauthorized access. They are often used in windows, doors, and fencing where strength and resilience are crucial. These grates can withstand force while providing a clear line of sight, combining security with transparency - a balance often required in security design. The galvanisation process fortifies them against environmental exposure, ensuring longevity in demanding security environments. This role exemplifies the expertise involved in creating dependable security solutions. Reflecting on real-world experiences, the versatility of galvanised metal grates becomes evident. Homeowners appreciate their utility in garden and landscape projects, where drainage, security, and aesthetic aspects must coexist harmoniously. Industries, on the other hand, test their mettle daily in rigorous settings, from chemical plants to heavy manufacturing units, where their performance directly impacts operational efficiency and safety. Choosing galvanised metal grates requires consideration of the quality of galvanisation; thickness, coating, and method influence their suitability for specific uses. Trustworthy manufacturers ensure compliance with industry standards, thereby enhancing the reliability of these products. Engaging with suppliers who understand the nuanced requirements of different applications is crucial in selecting the right product. In conclusion, the diverse applications of galvanised metal grates span from industrial safety solutions to architectural elegance, underscoring their indispensable role in various sectors. Their corrosion resistance, strength, and durability speak to the expert craftsmanship involved in their creation. As infrastructure continually evolves, the need for reliable, authoritative solutions like galvanised metal grates persists, highlighting their continued relevance in meeting the multifaceted demands of modern industry and society.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024