- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 02, 2025 01:48

Back to list

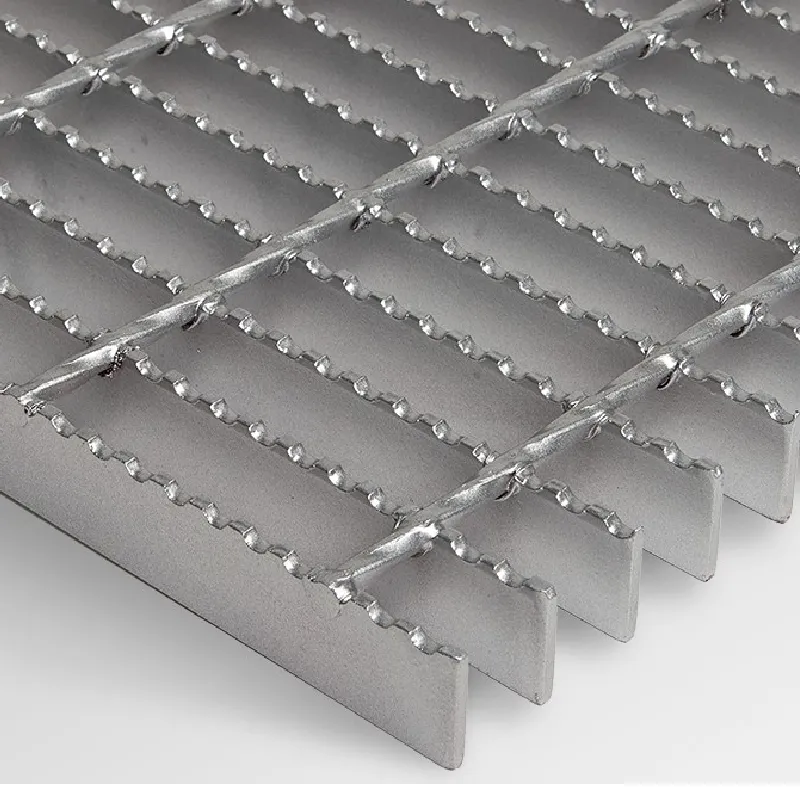

galvanized steel grating standard sizes

Selecting the right galvanized steel grating for your project can significantly impact the safety, durability, and efficiency of your infrastructure. As a seasoned professional in metal fabrication, my goal is to offer unique insights into galvanized steel grating standard sizes, helping you make informed decisions.

Choosing the right size requires a practical understanding of the project requirements, and insight into best practices established over years of professional experience. For environments subjected to extreme conditions, such as offshore platforms or chemical processing plants, corrosion resistance becomes paramount. This is where galvanized grating shines, offering a protective zinc coating that adheres to ASTM A123 standards, ensuring long-lasting performance even amidst harsh weather and corrosive agents. Additionally, compliance with safety standards such as the Occupational Safety and Health Administration (OSHA) regulations and the American National Standards Institute (ANSI) guidelines are critical. These standards emphasize the importance of selecting grating with appropriate load ratings, slip resistance characteristics, and structural integrity to prevent workplace accidents. Involving a professional engineer or specifier during the selection process can significantly enhance the decision-making process. These experts bring a wealth of knowledge and experience, ensuring that the selected galvanized steel grating not only meets project requirements but also aligns with industry standards for safety and performance. Experience has shown that a thoughtful approach to selecting the standard sizes of galvanized steel grating can lead to sturdy, safe, and sustainable installations. By understanding and implementing the nuances of sizing – from panel dimensions to bearing bar thickness and mesh spacing – you enhance the overall efficiency and longevity of your project infrastructure. In conclusion, while it may be tempting to choose galvanized steel grating based solely on cost or immediate availability, prioritizing standard sizes that appropriately match your specific requirements is crucial. This strategic approach ensures that the grating will provide optimal performance, safety, and durability throughout its service life. Relying on expert advice and adhering to recognized standards and regulations empowers project managers and engineers to make informed choices, cementing trust in the integrity of their installations long-term.

Choosing the right size requires a practical understanding of the project requirements, and insight into best practices established over years of professional experience. For environments subjected to extreme conditions, such as offshore platforms or chemical processing plants, corrosion resistance becomes paramount. This is where galvanized grating shines, offering a protective zinc coating that adheres to ASTM A123 standards, ensuring long-lasting performance even amidst harsh weather and corrosive agents. Additionally, compliance with safety standards such as the Occupational Safety and Health Administration (OSHA) regulations and the American National Standards Institute (ANSI) guidelines are critical. These standards emphasize the importance of selecting grating with appropriate load ratings, slip resistance characteristics, and structural integrity to prevent workplace accidents. Involving a professional engineer or specifier during the selection process can significantly enhance the decision-making process. These experts bring a wealth of knowledge and experience, ensuring that the selected galvanized steel grating not only meets project requirements but also aligns with industry standards for safety and performance. Experience has shown that a thoughtful approach to selecting the standard sizes of galvanized steel grating can lead to sturdy, safe, and sustainable installations. By understanding and implementing the nuances of sizing – from panel dimensions to bearing bar thickness and mesh spacing – you enhance the overall efficiency and longevity of your project infrastructure. In conclusion, while it may be tempting to choose galvanized steel grating based solely on cost or immediate availability, prioritizing standard sizes that appropriately match your specific requirements is crucial. This strategic approach ensures that the grating will provide optimal performance, safety, and durability throughout its service life. Relying on expert advice and adhering to recognized standards and regulations empowers project managers and engineers to make informed choices, cementing trust in the integrity of their installations long-term.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024