- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:44

Back to list

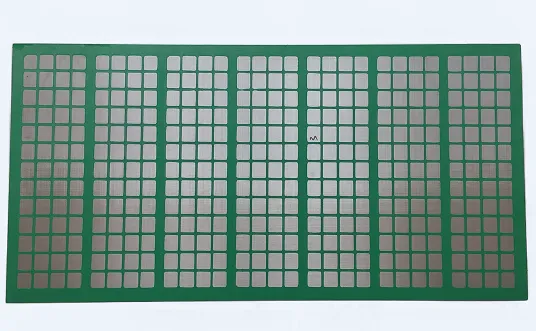

Steel Grating

Galvanized steel grating has emerged as an indispensable component across various industries due to its robustness, longevity, and adaptability. It is crafted from steel that has been coated with a layer of zinc, providing outstanding resistance against corrosion—one of its most valued attributes. This coating not only enhances the grating's durability but also ensures that it remains low-maintenance, making it a cost-effective solution over time.

A truly trustworthy provider of galvanized steel grating does not merely offer a product but enhances their service with expert consultation and tailored solutions. These companies work closely with clients to understand their specific demands, whether it’s for oil rigs, manufacturing facilities, or urban landscape projects. They guide clients through the selection process, elaborating on the benefits of different types of grating—like banded edge gratings or grating with kick plates—to ensure optimal application. Customer experiences consistently underline the relevance of galvanized steel grating's reliability and the strategic advantage it brings. Industry professionals trust it because it satisfies critical functional parameters while aligning with modern sustainability practices. Steel, as a recyclable material, ensures that even at the end of its lifecycle, the environmental impact is significantly reduced, adding an appealing dimension to ecologically-conscious companies. In conclusion, galvanized steel grating serves as a testament to engineering precision and sustainability. Its continued use across global markets underscores its critical role in facilitating safe, efficient, and long-lasting infrastructure. As industries evolve, the demand for such enduring materials, supported by expertise and trust, only stands to grow, highlighting its steadfast place in the future of construction and design.

A truly trustworthy provider of galvanized steel grating does not merely offer a product but enhances their service with expert consultation and tailored solutions. These companies work closely with clients to understand their specific demands, whether it’s for oil rigs, manufacturing facilities, or urban landscape projects. They guide clients through the selection process, elaborating on the benefits of different types of grating—like banded edge gratings or grating with kick plates—to ensure optimal application. Customer experiences consistently underline the relevance of galvanized steel grating's reliability and the strategic advantage it brings. Industry professionals trust it because it satisfies critical functional parameters while aligning with modern sustainability practices. Steel, as a recyclable material, ensures that even at the end of its lifecycle, the environmental impact is significantly reduced, adding an appealing dimension to ecologically-conscious companies. In conclusion, galvanized steel grating serves as a testament to engineering precision and sustainability. Its continued use across global markets underscores its critical role in facilitating safe, efficient, and long-lasting infrastructure. As industries evolve, the demand for such enduring materials, supported by expertise and trust, only stands to grow, highlighting its steadfast place in the future of construction and design.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024