- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:40

Back to list

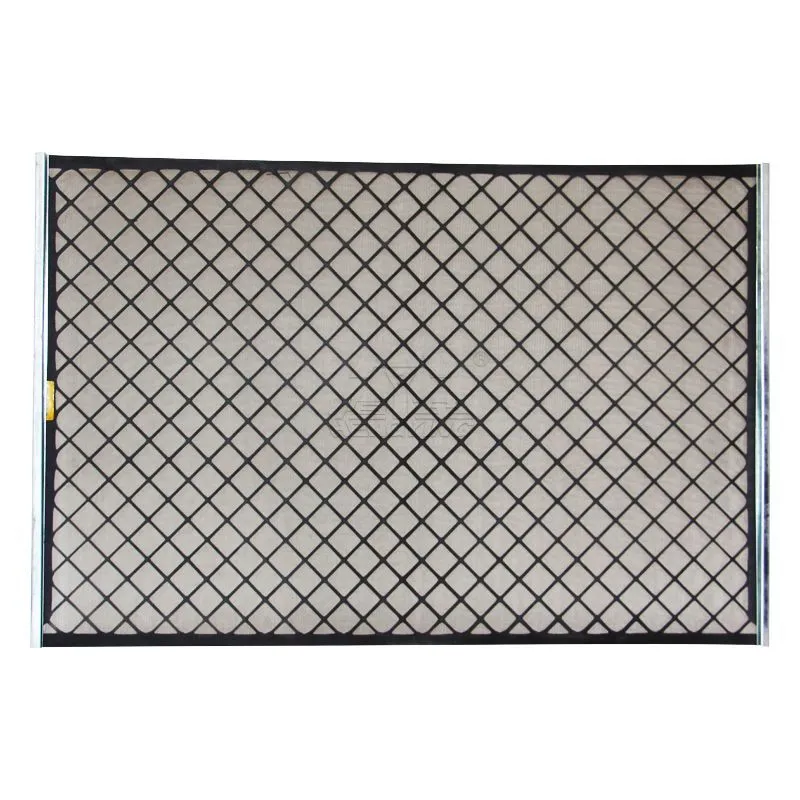

Steel Grating

Steel grating, an essential component in many industrial and commercial applications, offers unique benefits that can't be overlooked. Designed to provide sturdy and reliable flooring solutions, it plays a crucial role in settings ranging from factories to walkways to drainage covers. With its combination of strength, durability, and versatility, steel grating has become an authoritative choice for engineers and architects around the world.

Trustworthiness is further bolstered by the transparent sourcing of materials and ethical manufacturing practices. Steel, being a recyclable material, aligns with sustainable building goals and environmental considerations. Many manufacturers provide comprehensive certificates of compliance and traceability for their products, reinforcing trust and reliability for procurement managers and decision-makers invested in sustainable development. When considering the integration of steel grating into a project, it's important for professionals to assess the specific needs and challenges of their application. Factors such as load rating, environmental conditions, and even aesthetic considerations should guide the selection of the appropriate type of steel grating. Consulting with seasoned experts in the field can also provide invaluable insights tailored to individual project requirements, ensuring optimal performance and cost-effectiveness. Overall, the continued reliance on steel grating in numerous sectors underscores its pivotal role in construction and infrastructure. Its proven track record, backed by robust expertise and authoritative support, positions steel grating as a trustworthy choice for modern architecture and engineering demands. By combining functionality with reliability, steel grating stands as a testament to innovation and enduring quality in material solutions.

Trustworthiness is further bolstered by the transparent sourcing of materials and ethical manufacturing practices. Steel, being a recyclable material, aligns with sustainable building goals and environmental considerations. Many manufacturers provide comprehensive certificates of compliance and traceability for their products, reinforcing trust and reliability for procurement managers and decision-makers invested in sustainable development. When considering the integration of steel grating into a project, it's important for professionals to assess the specific needs and challenges of their application. Factors such as load rating, environmental conditions, and even aesthetic considerations should guide the selection of the appropriate type of steel grating. Consulting with seasoned experts in the field can also provide invaluable insights tailored to individual project requirements, ensuring optimal performance and cost-effectiveness. Overall, the continued reliance on steel grating in numerous sectors underscores its pivotal role in construction and infrastructure. Its proven track record, backed by robust expertise and authoritative support, positions steel grating as a trustworthy choice for modern architecture and engineering demands. By combining functionality with reliability, steel grating stands as a testament to innovation and enduring quality in material solutions.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024