- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 18:29

Back to list

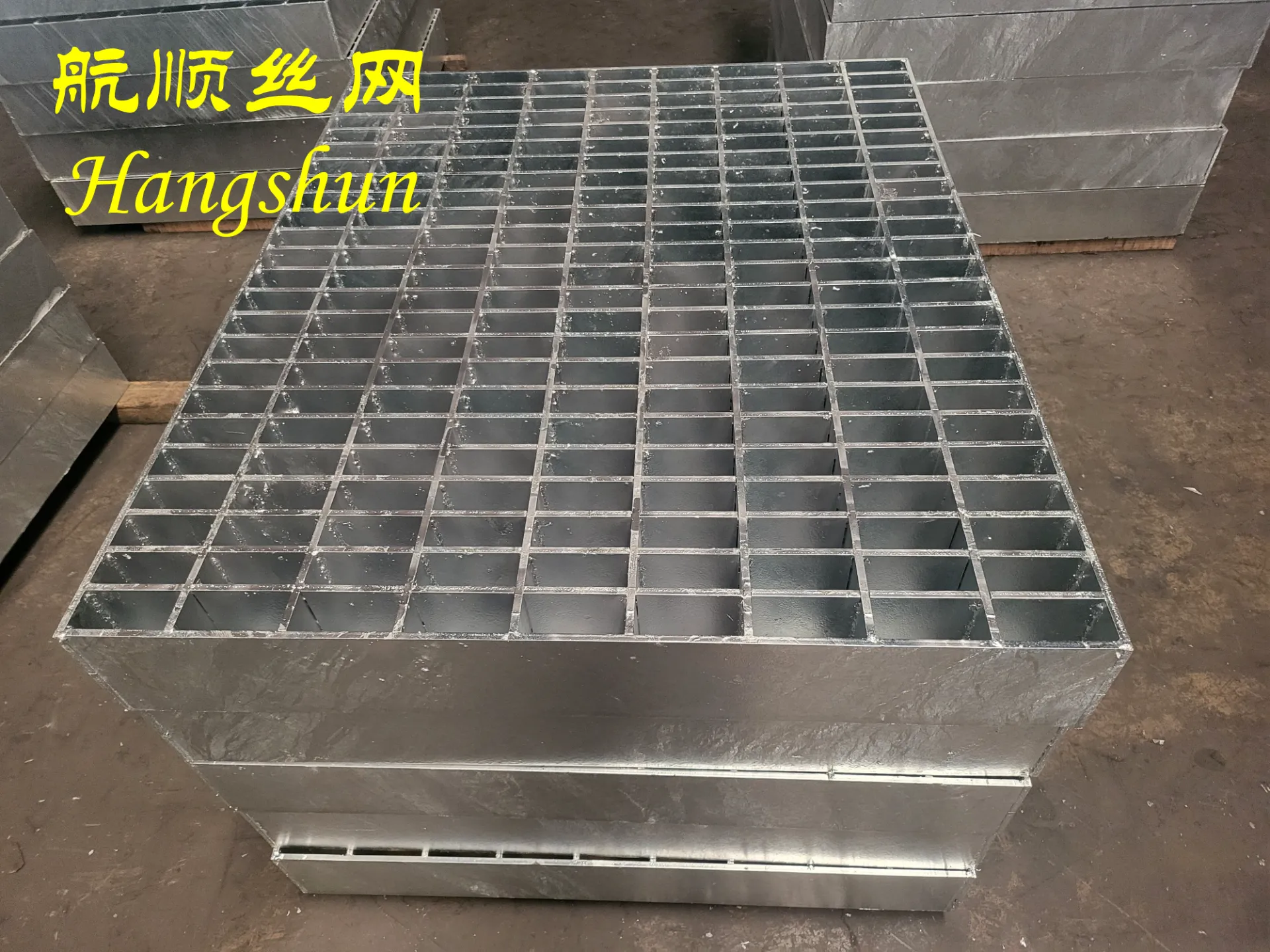

Press-Locked Steel Grating

Galvanized serrated grating is rapidly becoming a standout choice for industries seeking durability, safety, and long-term value. This type of grating is not only robust but also delivers a unique combination of features that make it the preferred option for a wide range of applications. Understanding its composition, benefits, and usage will equip anyone in the field with the insights necessary to make informed purchasing decisions.

When it comes to authoritativeness, suppliers of galvanized serrated grating build their credibility through quality assurance, adherence to standards, and comprehensive customer support. Reputable suppliers will provide certification of compliance with international safety and quality standards. Moreover, they often offer guidance on installation and maintenance, underscoring their commitment to long-term customer success. The trustworthiness of galvanized serrated grating suppliers can be evaluated based on their market reputation, customer feedback, and service track record. Transparent communication regarding product specifications, delivery times, and post-sale support further solidifies their reliability. Many suppliers prioritize establishing enduring relationships with their clients by offering robust warranties and responsive customer service teams. In practice, choosing the right galvanized serrated grating can significantly impact the efficiency and safety of an operation. For instance, a manufacturing facility experiencing frequent equipment downtimes due to floor corrosion could drastically reduce interruptions by switching to galvanized serrated grating. Similarly, in public transportation facilities, where daily foot traffic is immense, the enhanced grip provided by the serrated design can prevent accidents, thereby safeguarding both patrons and employees. In conclusion, galvanized serrated grating is a versatile, reliable solution that caters to diverse industrial needs. Its combination of strength, safety, and durability, underpinned by the expertise of seasoned suppliers, makes it a compelling choice for enterprises aiming to uphold rigorous safety and operational standards. For anyone vested in the realms of industrial or commercial development, investing in galvanized serrated grating signifies a commitment to quality and safety, promising long-term operational benefits and peace of mind.

When it comes to authoritativeness, suppliers of galvanized serrated grating build their credibility through quality assurance, adherence to standards, and comprehensive customer support. Reputable suppliers will provide certification of compliance with international safety and quality standards. Moreover, they often offer guidance on installation and maintenance, underscoring their commitment to long-term customer success. The trustworthiness of galvanized serrated grating suppliers can be evaluated based on their market reputation, customer feedback, and service track record. Transparent communication regarding product specifications, delivery times, and post-sale support further solidifies their reliability. Many suppliers prioritize establishing enduring relationships with their clients by offering robust warranties and responsive customer service teams. In practice, choosing the right galvanized serrated grating can significantly impact the efficiency and safety of an operation. For instance, a manufacturing facility experiencing frequent equipment downtimes due to floor corrosion could drastically reduce interruptions by switching to galvanized serrated grating. Similarly, in public transportation facilities, where daily foot traffic is immense, the enhanced grip provided by the serrated design can prevent accidents, thereby safeguarding both patrons and employees. In conclusion, galvanized serrated grating is a versatile, reliable solution that caters to diverse industrial needs. Its combination of strength, safety, and durability, underpinned by the expertise of seasoned suppliers, makes it a compelling choice for enterprises aiming to uphold rigorous safety and operational standards. For anyone vested in the realms of industrial or commercial development, investing in galvanized serrated grating signifies a commitment to quality and safety, promising long-term operational benefits and peace of mind.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024