- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 18:53

Back to list

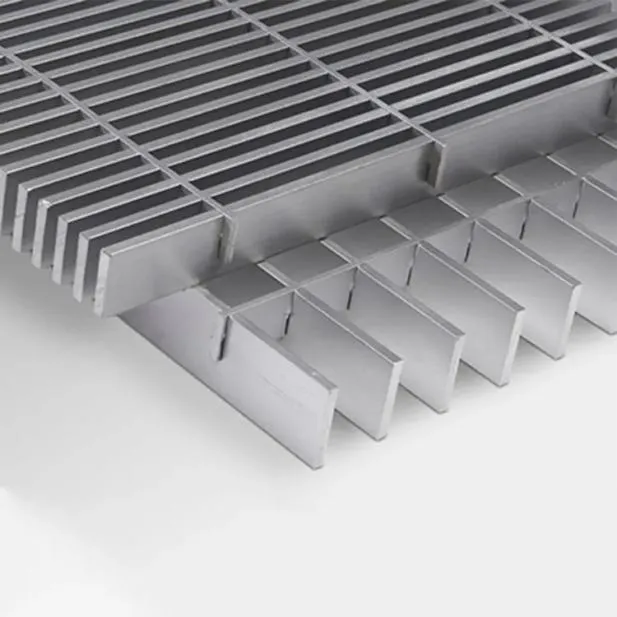

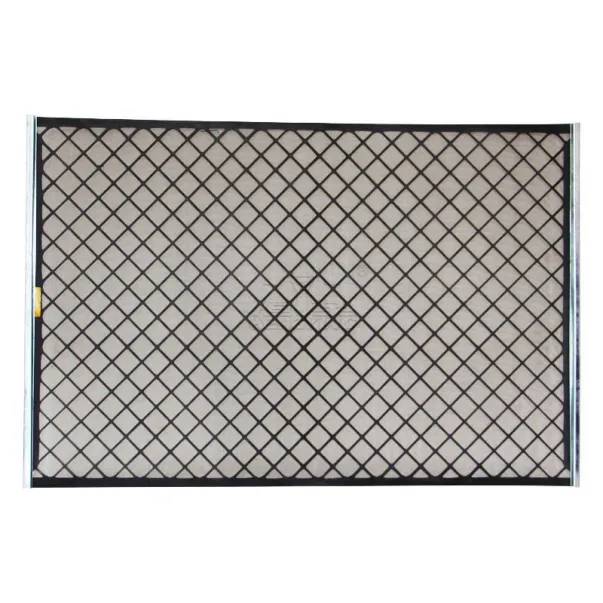

Steel Grating

In the realm of industrial and construction materials, grating galvanized iron emerges as an unsung hero, fortifying structures with its unmatched durability and robustness. The grating galv iron, with its distinctive features and versatile applications, stands as a testament to engineering prowess. This product seamlessly amalgamates longevity with strength, making it an indispensable asset in a myriad of projects.

Moreover, grating galvanized iron aligns with sustainability goals, a priority in today's conscientious construction environment. The galvanized coating prolongs the lifecycle of the iron, reducing the need for frequent replacements. This longevity translates into tangible environmental benefits, curtailing waste and minimizing the carbon footprint associated with manufacturing new materials. Its eco-friendly credentials make it a top contender in projects aiming for sustainability certifications. From a trustworthiness perspective, grating galv iron is manufactured under stringent quality control measures. Reputable manufacturers adhere to international standards, ensuring that each piece of grating meets the requisite safety and performance benchmarks. This rigorous quality assurance process inspires confidence among engineers and contractors, allowing them to embark on projects knowing they are backed by materials that won't falter under pressure. In essence, the story of grating galvanized iron is one of enduring performance, assured safety, and proactive sustainability. Its integration into projects speaks to a broader narrative of building towards a future that prizes durability without compromising on quality or safety. For professionals seeking materials that offer a blend of strength, security, and eco-consciousness, grating galv iron is an invaluable ally. As industries progress towards more demanding and challenging projects, the role of materials that can deliver reliable performance cannot be overstated. Grating galvanized iron stands ready to meet these challenges head-on, its legacy cemented by decades of proven service. For those in pursuit of excellence in their infrastructural endeavors, it offers not just a material, but a promise of unwavering quality and longevity.

Moreover, grating galvanized iron aligns with sustainability goals, a priority in today's conscientious construction environment. The galvanized coating prolongs the lifecycle of the iron, reducing the need for frequent replacements. This longevity translates into tangible environmental benefits, curtailing waste and minimizing the carbon footprint associated with manufacturing new materials. Its eco-friendly credentials make it a top contender in projects aiming for sustainability certifications. From a trustworthiness perspective, grating galv iron is manufactured under stringent quality control measures. Reputable manufacturers adhere to international standards, ensuring that each piece of grating meets the requisite safety and performance benchmarks. This rigorous quality assurance process inspires confidence among engineers and contractors, allowing them to embark on projects knowing they are backed by materials that won't falter under pressure. In essence, the story of grating galvanized iron is one of enduring performance, assured safety, and proactive sustainability. Its integration into projects speaks to a broader narrative of building towards a future that prizes durability without compromising on quality or safety. For professionals seeking materials that offer a blend of strength, security, and eco-consciousness, grating galv iron is an invaluable ally. As industries progress towards more demanding and challenging projects, the role of materials that can deliver reliable performance cannot be overstated. Grating galvanized iron stands ready to meet these challenges head-on, its legacy cemented by decades of proven service. For those in pursuit of excellence in their infrastructural endeavors, it offers not just a material, but a promise of unwavering quality and longevity.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024