- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 18:04

Back to list

Steel Grating

When evaluating the costs associated with galvanized grating, it is crucial to understand the various factors that influence pricing, as well as the long-term benefits that justify the investment. Galvanized grating is a versatile material used in a variety of applications, including industrial flooring, walkways, and platforms. Its popularity stems from its durability, corrosion resistance, and cost-effectiveness compared to other materials.

A critical benefit of galvanized grating is its eco-friendliness — an increasingly important consideration in modern project planning. The galvanization process is energy-efficient and produces minimal waste, while the longevity of the grating reduces material turnover. This contributes to sustainability goals and can be a major selling point for companies positioning themselves as environmentally responsible. Moreover, galvanized grating's low maintenance requirement is a substantial cost advantage. Routine inspections and occasional cleaning are usually sufficient to maintain its condition, as opposed to untreated steel, which may need regular repainting or replacement due to corrosion. This reduced upkeep saves both time and resources, making galvanized grating an economically sound choice for facility managers and project planners. The industry expertise required to select and maintain galvanized grating cannot be underestimated. Working with experienced professionals in the field provides access to detailed knowledge and insights that can optimize both the selection and maintenance processes. Trusted industry consultants can offer strategic advice tailored to specific project needs, ensuring a blend of cost-efficiency and performance. Lastly, it is essential to consider the warranties and guarantees offered by manufacturers. Leading suppliers often provide comprehensive warranty packages that offer peace of mind, knowing that the investment is protected against manufacturing defects or unexpected failures. This assurance underscores the trustworthiness and reliability of galvanized grating as an investment. In conclusion, while the initial cost of galvanized grating might be higher compared to other materials, its long-term benefits, including durability, low maintenance, and environmental sustainability, make it a cost-effective solution. By considering factors such as material quality, design specifications, and market conditions, and by collaborating with experienced professionals, businesses can make informed decisions that align with both their economic and operational goals.

A critical benefit of galvanized grating is its eco-friendliness — an increasingly important consideration in modern project planning. The galvanization process is energy-efficient and produces minimal waste, while the longevity of the grating reduces material turnover. This contributes to sustainability goals and can be a major selling point for companies positioning themselves as environmentally responsible. Moreover, galvanized grating's low maintenance requirement is a substantial cost advantage. Routine inspections and occasional cleaning are usually sufficient to maintain its condition, as opposed to untreated steel, which may need regular repainting or replacement due to corrosion. This reduced upkeep saves both time and resources, making galvanized grating an economically sound choice for facility managers and project planners. The industry expertise required to select and maintain galvanized grating cannot be underestimated. Working with experienced professionals in the field provides access to detailed knowledge and insights that can optimize both the selection and maintenance processes. Trusted industry consultants can offer strategic advice tailored to specific project needs, ensuring a blend of cost-efficiency and performance. Lastly, it is essential to consider the warranties and guarantees offered by manufacturers. Leading suppliers often provide comprehensive warranty packages that offer peace of mind, knowing that the investment is protected against manufacturing defects or unexpected failures. This assurance underscores the trustworthiness and reliability of galvanized grating as an investment. In conclusion, while the initial cost of galvanized grating might be higher compared to other materials, its long-term benefits, including durability, low maintenance, and environmental sustainability, make it a cost-effective solution. By considering factors such as material quality, design specifications, and market conditions, and by collaborating with experienced professionals, businesses can make informed decisions that align with both their economic and operational goals.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

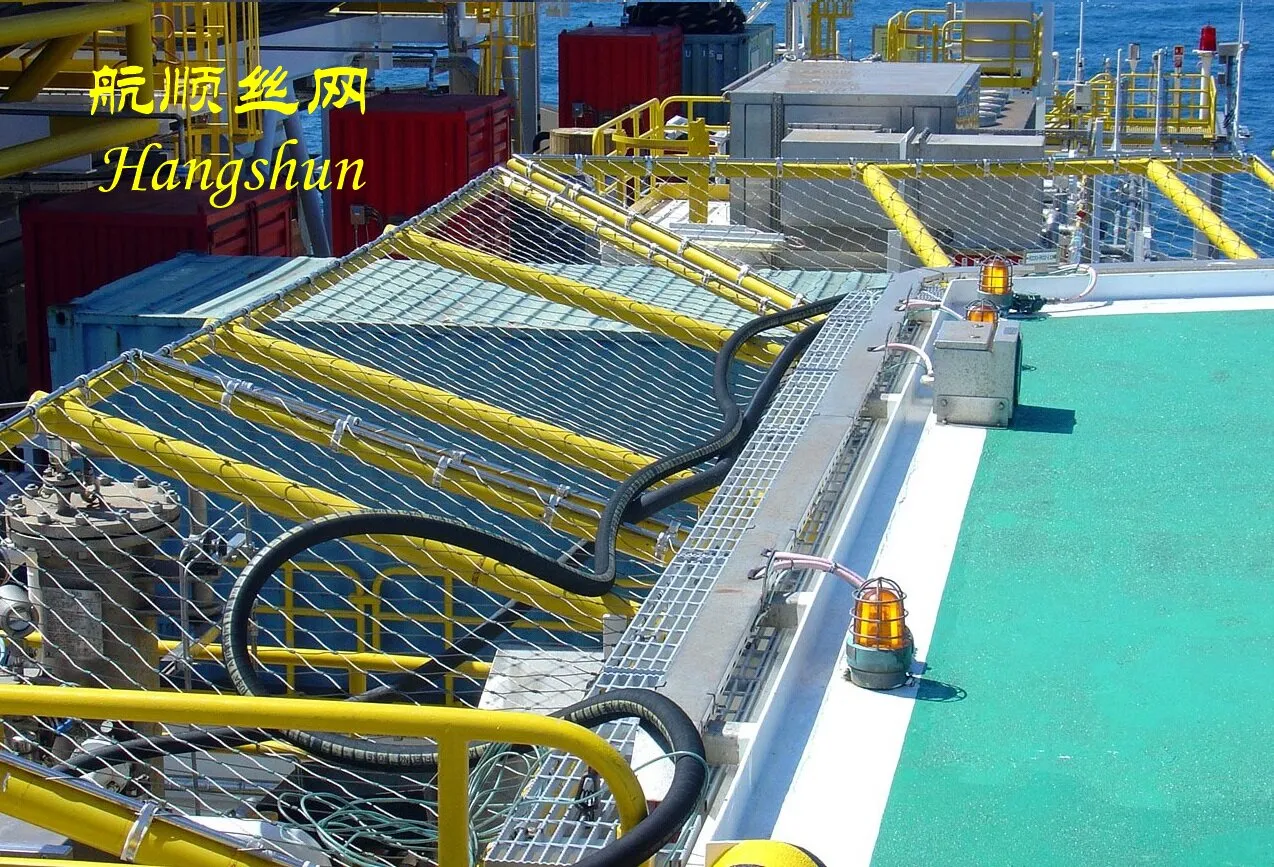

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024