- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 16:47

Back to list

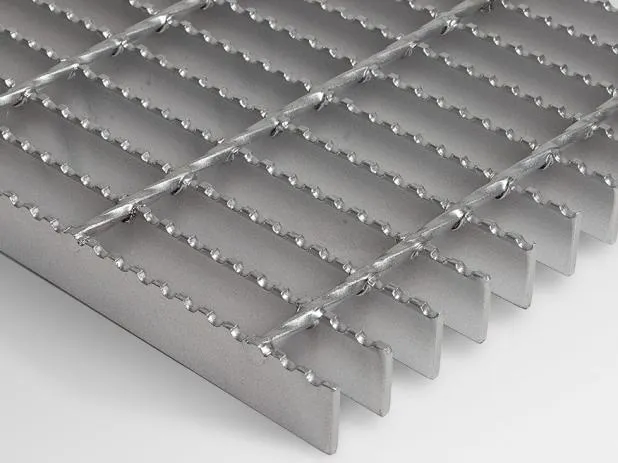

Riveted Grating

Floor grating steel stands as a vital component in numerous industrial and architectural applications, renowned for its strength, versatility, and durability. In the realms of construction and manufacturing, the floors one walks on must be as reliable as the foundations beneath them, and steel grating provides a tried-and-true solution.

Authoritativeness in the field of steel grating is reflected in the adherence to international standards. Compliance with standards such as ISO and ANSI guarantees that the products meet stringent safety and quality requirements. Suppliers and manufacturers who prioritize these certifications are committing to quality assurance, which fosters trust among their clientele. Buyers are encouraged to consider manufacturers with these accreditations as it provides peace of mind that their purchase is both safe and of superior quality. For architects and designers, steel grating also factors into aesthetic considerations. Its sleek, industrial look can be integrated into modern architectural designs, providing both form and function. This is particularly prevalent in urban renewal projects or in spaces where industrial chic is desired. Steel grating’s ability to serve as both a structural necessity and a design element demonstrates its versatility beyond traditional applications. Lastly, trustworthiness in the context of floor grating steel comes from a track record of successful installations and satisfied customers. Testimonials and case studies featuring projects where steel grating has been effectively utilized lend credibility to its continued use. Companies that highlight these success stories on their platforms cultivate trust and attract potential customers who are seeking reliable solutions. To conclude, floor grating steel combines robust functionality with expert flexibility, extending its use across various sectors due to its proven dependability and efficiency. Its integration into projects—from safety-focused industrial applications to trendsetting architectural designs—exemplifies its widespread appeal. By considering factors such as type, finish, and compliance with standards, businesses and builders alike can harness the full potential of steel grating, ensuring safe and aesthetically pleasing environments for years to come. In an evolving market, the prospects of floor grating steel shine brightly, poised to meet the challenges of both today and tomorrow.

Authoritativeness in the field of steel grating is reflected in the adherence to international standards. Compliance with standards such as ISO and ANSI guarantees that the products meet stringent safety and quality requirements. Suppliers and manufacturers who prioritize these certifications are committing to quality assurance, which fosters trust among their clientele. Buyers are encouraged to consider manufacturers with these accreditations as it provides peace of mind that their purchase is both safe and of superior quality. For architects and designers, steel grating also factors into aesthetic considerations. Its sleek, industrial look can be integrated into modern architectural designs, providing both form and function. This is particularly prevalent in urban renewal projects or in spaces where industrial chic is desired. Steel grating’s ability to serve as both a structural necessity and a design element demonstrates its versatility beyond traditional applications. Lastly, trustworthiness in the context of floor grating steel comes from a track record of successful installations and satisfied customers. Testimonials and case studies featuring projects where steel grating has been effectively utilized lend credibility to its continued use. Companies that highlight these success stories on their platforms cultivate trust and attract potential customers who are seeking reliable solutions. To conclude, floor grating steel combines robust functionality with expert flexibility, extending its use across various sectors due to its proven dependability and efficiency. Its integration into projects—from safety-focused industrial applications to trendsetting architectural designs—exemplifies its widespread appeal. By considering factors such as type, finish, and compliance with standards, businesses and builders alike can harness the full potential of steel grating, ensuring safe and aesthetically pleasing environments for years to come. In an evolving market, the prospects of floor grating steel shine brightly, poised to meet the challenges of both today and tomorrow.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024