- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 16:30

Back to list

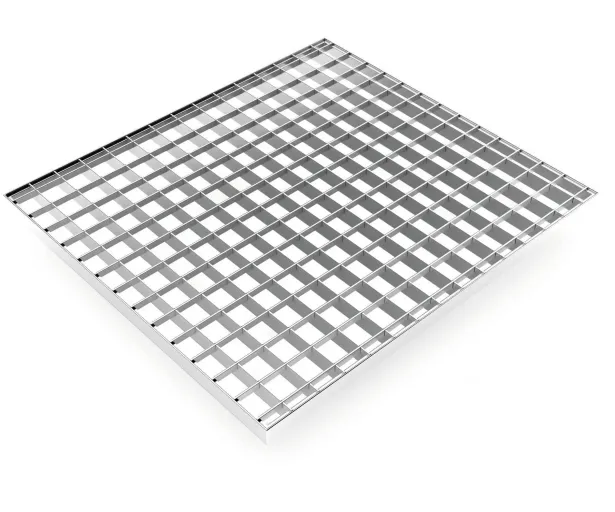

Welded Steel Grating

For anyone diving into the world of industrial flooring solutions, bar grating is likely a term that will surface consistently. An essential material in various sectors, bar grating provides strength, safety, and durability for platforms, walkways, and stair treads. Understanding bar grating sizes is integral for selecting the appropriate type for your specific application. This exploration into bar grating sizes will unveil insights into its varied dimensions and specifications, offering practical knowledge drawn from real-world experience and expertise.

Expertise drawn from applications in refinery platforms to urban infrastructures suggests that the environment is a decisive factor in selecting grating size. Corrosion-prone settings, like chemical processing plants or coastal areas, often require grating with larger bearing bars and stainless steel material to withstand harsh conditions. Moreover, the spacing between bars matters significantly, classified into terms like ‘close mesh’ or ‘wide mesh’. Close mesh, where bars are spaced narrowly, provides additional safety in pedestrian areas where stiletto heels or small debris can cause issues. One quintessential aspect underlined by experience is safety compliance. Ensure the grating selected conforms to standards like those outlined by the American National Standards Institute (ANSI) or Occupational Safety and Health Administration (OSHA). Proper sizing exceeding these standards can mitigate hazards, ensuring a safe environment for its intended use. In summary, selecting the right bar grating size is more than measuring dimensions; it’s about aligning practical needs with industry standards and environmental considerations. By understanding the intricate specification matrices that include bar sizes, thickness, material choice, and spacing, a savvy professional can ensure they select the most appropriate grating for their project’s needs. All these factors, when combined, amplify the durability, safety, and efficiency of the final installation. Thus, approaching bar grating selection with a comprehensive view strengthens the foundation, both literally and metaphorically, benefiting industries and communities alike.

Expertise drawn from applications in refinery platforms to urban infrastructures suggests that the environment is a decisive factor in selecting grating size. Corrosion-prone settings, like chemical processing plants or coastal areas, often require grating with larger bearing bars and stainless steel material to withstand harsh conditions. Moreover, the spacing between bars matters significantly, classified into terms like ‘close mesh’ or ‘wide mesh’. Close mesh, where bars are spaced narrowly, provides additional safety in pedestrian areas where stiletto heels or small debris can cause issues. One quintessential aspect underlined by experience is safety compliance. Ensure the grating selected conforms to standards like those outlined by the American National Standards Institute (ANSI) or Occupational Safety and Health Administration (OSHA). Proper sizing exceeding these standards can mitigate hazards, ensuring a safe environment for its intended use. In summary, selecting the right bar grating size is more than measuring dimensions; it’s about aligning practical needs with industry standards and environmental considerations. By understanding the intricate specification matrices that include bar sizes, thickness, material choice, and spacing, a savvy professional can ensure they select the most appropriate grating for their project’s needs. All these factors, when combined, amplify the durability, safety, and efficiency of the final installation. Thus, approaching bar grating selection with a comprehensive view strengthens the foundation, both literally and metaphorically, benefiting industries and communities alike.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024