- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 17:06

Back to list

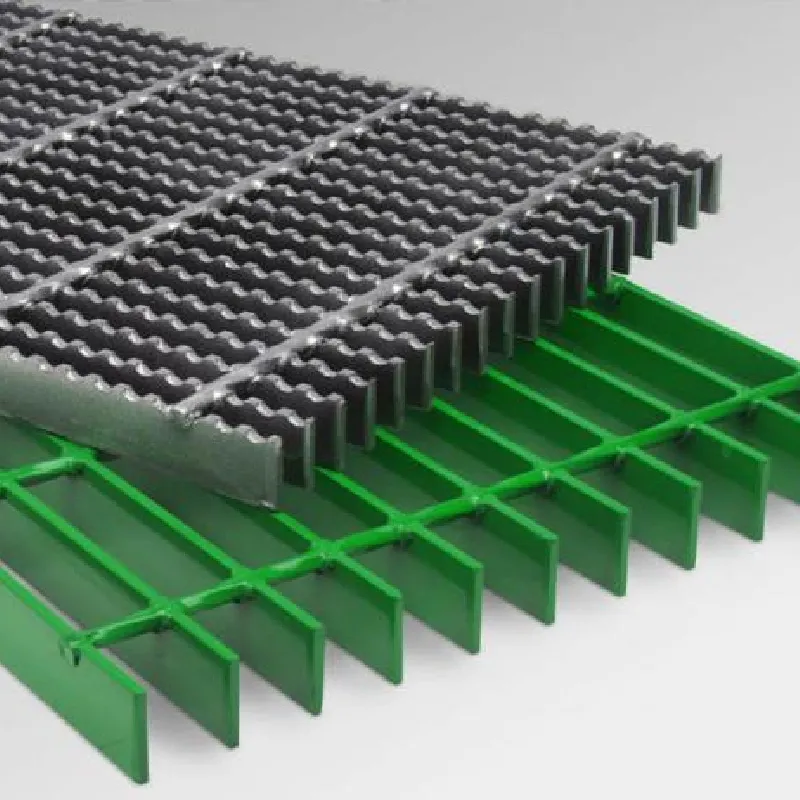

Steel Grating

The 19w4 grating technology represents a pivotal advancement in the field of optical gratings, a domain where precision, innovation, and application-specific customization play paramount roles. Gratings, essential in the manipulation and measurement of light, serve as crucial components in spectrometry, telecommunications, and laser systems, among other high-tech applications. The emergence of the 19w4 grating introduces significant enhancements in efficiency, precision, and application diversification, offering newfound possibilities in multiple industries.

Furthermore, its robust design and customizable features cater to the growing demand in research and industry for tailor-made optical solutions. Customization is crucial in applications such as laser manufacturing, where specific grating dimensions and properties can significantly impact laser output quality and efficiency. The 19w4 grating can be engineered with varying groove densities and blaze angles to meet these bespoke requirements, thereby establishing itself as a versatile tool for engineers and scientists seeking precision instrumentation. Another critical advantage of the 19w4 grating is its integration capabilities with other optical components. Complex optical systems often require seamless interfacing between different hardware elements to ensure optimal performance. The compatibility of the 19w4 grating with a range of substrates and its ease of integration make it a favored choice among system designers. Its ability to harmonize with lenses, mirrors, and detectors without causing aberrations or alignment issues contributes to the integrity and efficacy of optical setups across various applications. Trust in optical equipment often hinges on proven expertise and a history of successful deployments. Manufacturers associated with 19w4 grating technology bring a wealth of experience, supported by rigorous testing and quality assurance protocols. This reliability is substantiated by adherence to industry standards and certifications, which bolster confidence among users and regulators alike. As a result, the trustworthiness inherent in the 19w4 grating facilitates its adoption in critical applications such as aerospace technology, medical imaging, and scientific research, where equipment failure and inaccuracies are unacceptable. In conclusion, the 19w4 grating stands as a testament to the intersection of experience-driven innovation and the demand for precision in optical technology. Its enhancements in efficiency, thermal stability, adaptability, and system integration make it a formidable contender in the optical component market. As industries continue to evolve, the role of advanced grating technologies like the 19w4 will undoubtedly expand, underscoring the necessity for optical components that not only meet but exceed the rigorous demands of contemporary scientific and industrial applications.

Furthermore, its robust design and customizable features cater to the growing demand in research and industry for tailor-made optical solutions. Customization is crucial in applications such as laser manufacturing, where specific grating dimensions and properties can significantly impact laser output quality and efficiency. The 19w4 grating can be engineered with varying groove densities and blaze angles to meet these bespoke requirements, thereby establishing itself as a versatile tool for engineers and scientists seeking precision instrumentation. Another critical advantage of the 19w4 grating is its integration capabilities with other optical components. Complex optical systems often require seamless interfacing between different hardware elements to ensure optimal performance. The compatibility of the 19w4 grating with a range of substrates and its ease of integration make it a favored choice among system designers. Its ability to harmonize with lenses, mirrors, and detectors without causing aberrations or alignment issues contributes to the integrity and efficacy of optical setups across various applications. Trust in optical equipment often hinges on proven expertise and a history of successful deployments. Manufacturers associated with 19w4 grating technology bring a wealth of experience, supported by rigorous testing and quality assurance protocols. This reliability is substantiated by adherence to industry standards and certifications, which bolster confidence among users and regulators alike. As a result, the trustworthiness inherent in the 19w4 grating facilitates its adoption in critical applications such as aerospace technology, medical imaging, and scientific research, where equipment failure and inaccuracies are unacceptable. In conclusion, the 19w4 grating stands as a testament to the intersection of experience-driven innovation and the demand for precision in optical technology. Its enhancements in efficiency, thermal stability, adaptability, and system integration make it a formidable contender in the optical component market. As industries continue to evolve, the role of advanced grating technologies like the 19w4 will undoubtedly expand, underscoring the necessity for optical components that not only meet but exceed the rigorous demands of contemporary scientific and industrial applications.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024