- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 19:49

Back to list

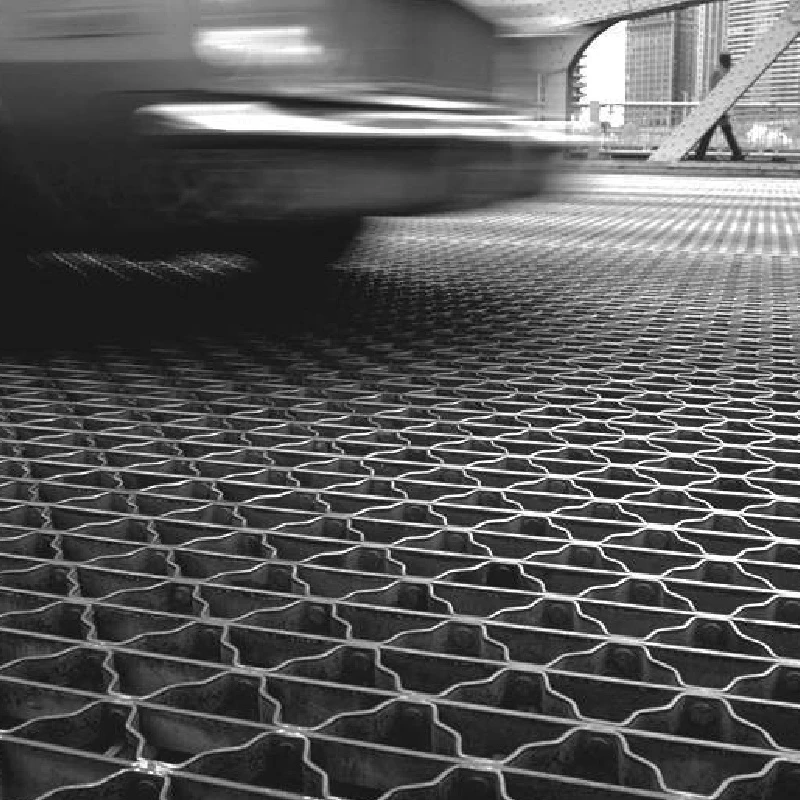

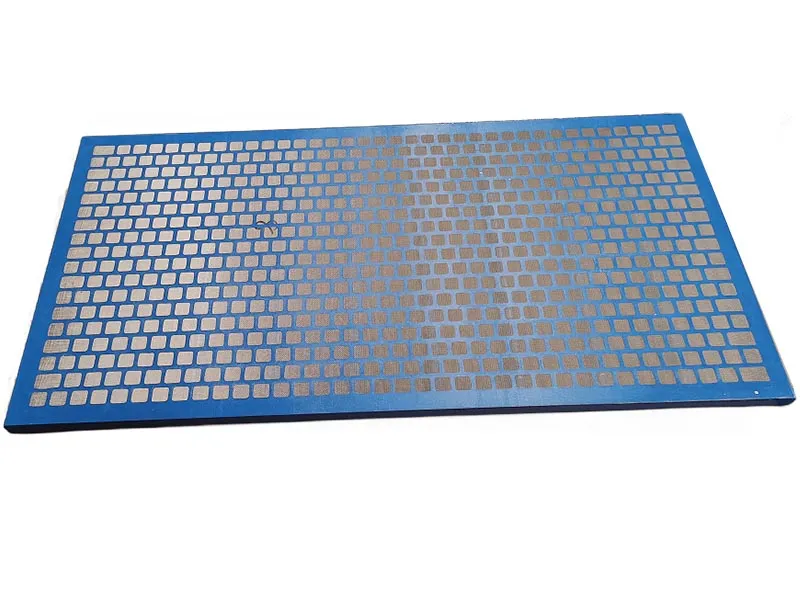

floor grating panels

Floor grating panels are an indispensable component in numerous industrial applications. They provide a robust, anti-slip surface that ensures safety while offering versatility and durability. To understand the full potential and utility of floor grating panels, it is necessary to delve deeper into their features, variety, and specific applications. These panels are not only a choice for enhancing safety but also stand as a testament to engineering excellence, meeting the stringent demands of contemporary industrial environments.

Furthermore, the installation process of floor grating panels is designed to be straightforward, minimizing downtime and ensuring that any interruption to operations is kept to a minimum. Their lightweight feature, particularly with aluminum and fiberglass variants, allows for easier handling and quicker installation. This efficiency is critical in industries where time is of the essence, enabling swift installation, replacement, or removal when necessary. Regulations and standards govern the production and application of floor grating panels, ensuring they meet industry-specific safety and quality requirements. Existing standards from organizations such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) ensure that these products are manufactured to the highest safety standards. Utilizing floor grating panels that comply with these regulations not only guarantees safety but also enhances the credibility of the business using them. When evaluating different types of floor grating panels, cost considerations often come into play. While steel is typically more economical upfront, aluminum and fiberglass may offer better life-cycle cost savings due to their reduced maintenance requirements and long service life. Therefore, assessing the total cost of ownership is essential when making purchase decisions. Innovation in floor grating panel design continues to evolve with advancements in technology. The introduction of novel materials enhancing anti-slip performance, incorporating eco-friendly components, and utilizing enhanced fabrication techniques reflect the industry's strong commitment to safety and sustainability. Such innovations not only improve product performance but also help companies adhere to increasingly stringent environmental and safety regulations. In summary, floor grating panels stand out as versatile, durable, and essential components in various industrial settings. By offering tailored solutions, ensuring compliance with safety standards, and adapting to new technological advancements, these panels provide an invaluable resource for businesses seeking to maintain high safety standards and efficient operations. Their strategic application can significantly impact operational efficiency, safety, and profitability, underscoring their indispensable role in modern industry.

Furthermore, the installation process of floor grating panels is designed to be straightforward, minimizing downtime and ensuring that any interruption to operations is kept to a minimum. Their lightweight feature, particularly with aluminum and fiberglass variants, allows for easier handling and quicker installation. This efficiency is critical in industries where time is of the essence, enabling swift installation, replacement, or removal when necessary. Regulations and standards govern the production and application of floor grating panels, ensuring they meet industry-specific safety and quality requirements. Existing standards from organizations such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) ensure that these products are manufactured to the highest safety standards. Utilizing floor grating panels that comply with these regulations not only guarantees safety but also enhances the credibility of the business using them. When evaluating different types of floor grating panels, cost considerations often come into play. While steel is typically more economical upfront, aluminum and fiberglass may offer better life-cycle cost savings due to their reduced maintenance requirements and long service life. Therefore, assessing the total cost of ownership is essential when making purchase decisions. Innovation in floor grating panel design continues to evolve with advancements in technology. The introduction of novel materials enhancing anti-slip performance, incorporating eco-friendly components, and utilizing enhanced fabrication techniques reflect the industry's strong commitment to safety and sustainability. Such innovations not only improve product performance but also help companies adhere to increasingly stringent environmental and safety regulations. In summary, floor grating panels stand out as versatile, durable, and essential components in various industrial settings. By offering tailored solutions, ensuring compliance with safety standards, and adapting to new technological advancements, these panels provide an invaluable resource for businesses seeking to maintain high safety standards and efficient operations. Their strategic application can significantly impact operational efficiency, safety, and profitability, underscoring their indispensable role in modern industry.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024