- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 19:32

Back to list

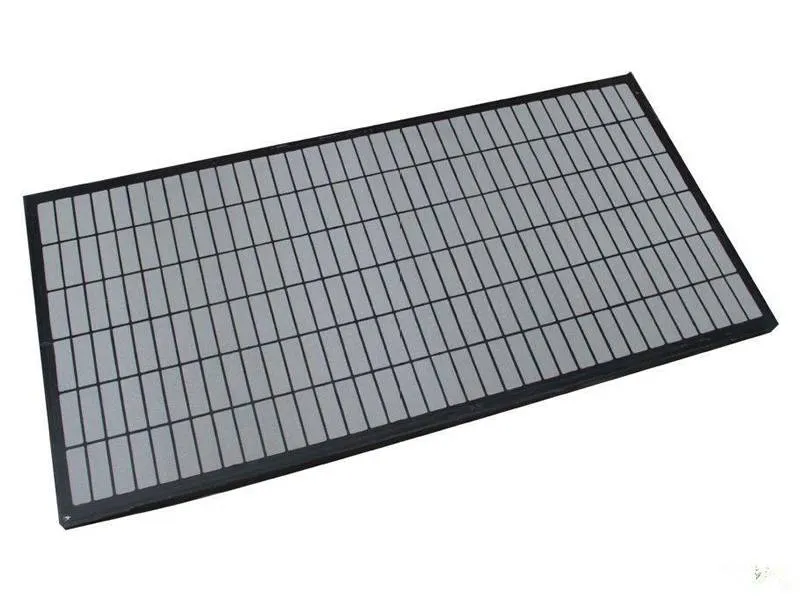

stainless bar grating

When contemplating the perfect material for your industrial flooring, stainless bar grating often stands out as an excellent choice. Its appeal lies in its remarkable blend of strength, durability, and versatility, making it a preferred choice for a range of applications, from walkways and platforms to drainage covers in bustling industrial environments. This article explores the various facets of stainless bar grating and offers insights that lean heavily on Experience, Expertise, Authoritativeness, and Trustworthiness.

Authoritativeness in the use of stainless bar grating is cemented by its endorsement in various engineering manuals and standards. Institutions like the American Institute of Steel Construction (AISC) and the National Association of Architectural Metal Manufacturers (NAAMM) provide guidelines and specifications that emphasize the reliability of stainless bar grating in structural applications. In projects where hygiene is paramount, such as in food processing plants, the choice of stainless bar grating extends beyond durability into maintenance efficiency. Stainless steel's non-porous surface prevents the absorption of contaminants, thereby simplifying the cleaning process. This contributes to a safer, more hygienic environment, curbing the risks of contamination—a significant factor for compliance with health regulations. Trustworthiness, another pillar in the evaluation of stainless bar grating, is evident in its track record. Clients from diverse industries place their trust in this material for high-stakes projects, citing not only its initial performance but also its low lifecycle costs. While the upfront investment may be higher compared to alternatives, the longevity and reduced maintenance expenses underscore substantial savings over time. Testimonials from industry leaders consistently highlight these benefits, reinforcing stainless bar grating's status as a smart investment. In conclusion, stainless bar grating's stronghold in the industrial sector is a reflection of its excellence across various parameters. Whether evaluated through the lenses of strength, versatility, corrosion resistance, or maintenance, it remains a superior choice for industrial flooring solutions. As industries evolve, the demand for reliable, durable, and adaptable materials like stainless bar grating is poised to grow, solidifying its place as a staple in modern engineering and construction projects.

Authoritativeness in the use of stainless bar grating is cemented by its endorsement in various engineering manuals and standards. Institutions like the American Institute of Steel Construction (AISC) and the National Association of Architectural Metal Manufacturers (NAAMM) provide guidelines and specifications that emphasize the reliability of stainless bar grating in structural applications. In projects where hygiene is paramount, such as in food processing plants, the choice of stainless bar grating extends beyond durability into maintenance efficiency. Stainless steel's non-porous surface prevents the absorption of contaminants, thereby simplifying the cleaning process. This contributes to a safer, more hygienic environment, curbing the risks of contamination—a significant factor for compliance with health regulations. Trustworthiness, another pillar in the evaluation of stainless bar grating, is evident in its track record. Clients from diverse industries place their trust in this material for high-stakes projects, citing not only its initial performance but also its low lifecycle costs. While the upfront investment may be higher compared to alternatives, the longevity and reduced maintenance expenses underscore substantial savings over time. Testimonials from industry leaders consistently highlight these benefits, reinforcing stainless bar grating's status as a smart investment. In conclusion, stainless bar grating's stronghold in the industrial sector is a reflection of its excellence across various parameters. Whether evaluated through the lenses of strength, versatility, corrosion resistance, or maintenance, it remains a superior choice for industrial flooring solutions. As industries evolve, the demand for reliable, durable, and adaptable materials like stainless bar grating is poised to grow, solidifying its place as a staple in modern engineering and construction projects.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024