- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 20:08

Back to list

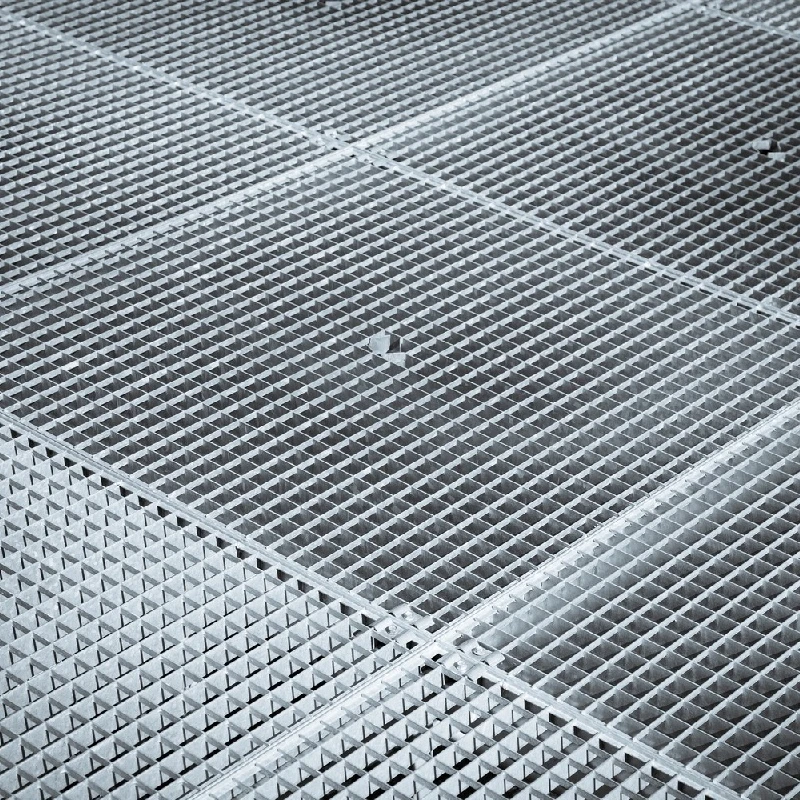

steel grating sizes

Steel grating is an essential component in various industrial and commercial applications, providing a versatile solution due to its durability, strength, and cost-effectiveness. Selecting the right steel grating size is crucial, depending on the specific needs of your project and understanding the different size options available can significantly impact the efficiency and safety of your operations.

1. Industrial Walkways and Platforms Steel grating in industries requires robust configurations, typically opting for thicker and higher bearing bars to support significant loads. Sizes like 1-1/4 inch by 1/4 inch are common, ensuring safety and durability in high-traffic areas. 2. Drainage Covers and Trench Grating In applications where drainage is a critical function, the size and spacing must allow for optimal water flow while maintaining structural integrity. Gratings with wider spacing allow for better flow but may need increased thickness to maintain strength. 3. Construction and Architectural Steel Grating While functionality is a priority, aesthetics also play a role in architectural applications. Custom-sized gratings can be specified to fit unique architectural designs, blending utility with visual appeal, without compromising on structural integrity. Expert Tips for Selecting the Right Steel Grating Size - Load Requirements Assess the maximum load capacity required for your application to determine the necessary bar height and thickness. - Environment Considerations Analyze environmental factors such as moisture, chemical exposure, and weather conditions, opting for suitable materials and coatings. - Compliance and Standards Ensure the selected grating size adheres to local safety and building regulations to prevent legal and safety issues. - Future-proofing Consider potential changes in the use or load requirements to select a size that allows for flexibility and adaptability in future applications. Choosing the correct steel grating size is not a one-size-fits-all process. Detailed assessment and understanding of the project requirements are crucial. Consulting with experienced engineers or grating manufacturers can provide valuable insights into the appropriate specifications, ensuring optimal performance and safety. As steel grating continues to evolve with advances in materials and technology, staying informed about new developments can also enhance project outcomes.

1. Industrial Walkways and Platforms Steel grating in industries requires robust configurations, typically opting for thicker and higher bearing bars to support significant loads. Sizes like 1-1/4 inch by 1/4 inch are common, ensuring safety and durability in high-traffic areas. 2. Drainage Covers and Trench Grating In applications where drainage is a critical function, the size and spacing must allow for optimal water flow while maintaining structural integrity. Gratings with wider spacing allow for better flow but may need increased thickness to maintain strength. 3. Construction and Architectural Steel Grating While functionality is a priority, aesthetics also play a role in architectural applications. Custom-sized gratings can be specified to fit unique architectural designs, blending utility with visual appeal, without compromising on structural integrity. Expert Tips for Selecting the Right Steel Grating Size - Load Requirements Assess the maximum load capacity required for your application to determine the necessary bar height and thickness. - Environment Considerations Analyze environmental factors such as moisture, chemical exposure, and weather conditions, opting for suitable materials and coatings. - Compliance and Standards Ensure the selected grating size adheres to local safety and building regulations to prevent legal and safety issues. - Future-proofing Consider potential changes in the use or load requirements to select a size that allows for flexibility and adaptability in future applications. Choosing the correct steel grating size is not a one-size-fits-all process. Detailed assessment and understanding of the project requirements are crucial. Consulting with experienced engineers or grating manufacturers can provide valuable insights into the appropriate specifications, ensuring optimal performance and safety. As steel grating continues to evolve with advances in materials and technology, staying informed about new developments can also enhance project outcomes.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024