- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 07:18

Back to list

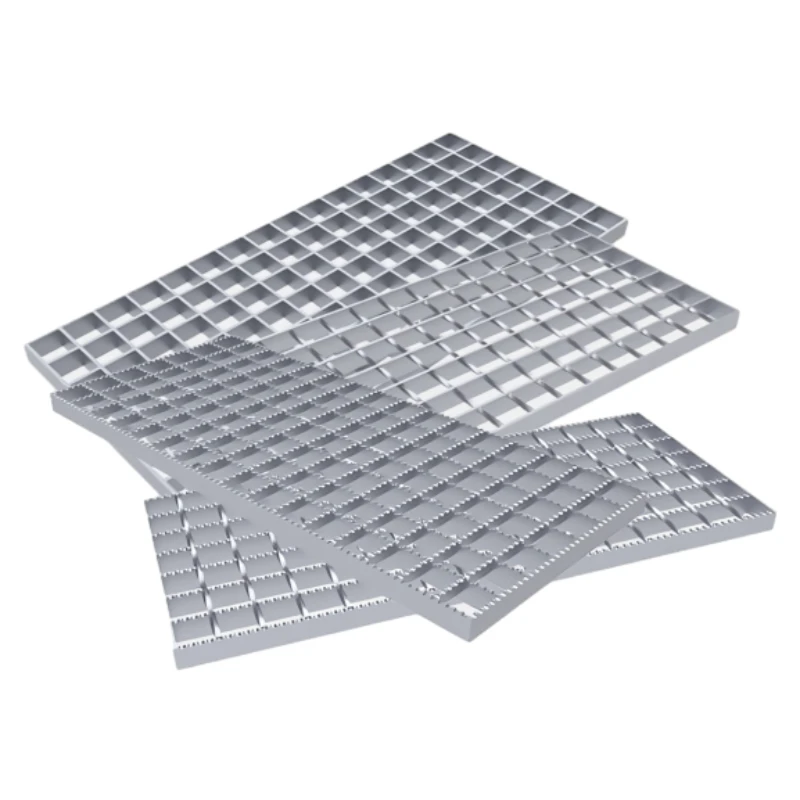

heavy-duty welded bar grating

Understanding the weight of bar grating per square foot is crucial for industries that rely on this durable material to build efficient, safe, and structurally sound platforms. Whether it's for industrial flooring, walkways, or stair treads, knowing how to calculate and assess bar grating weight is invaluable for architects, engineers, and project managers.

In terms of practical application, industry insiders often turn to standardized load tables and weight charts, tools essential for an accurate analysis of weight per square foot. Engineers and architects can thereby predict how the grating will perform under varying loads, customize grating to fit unique project requirements, and ensure compliance with local building codes and safety regulations. Trustworthy insights from field experts are crucial to navigate the intricacies of selecting the right bar grating. Choosing the appropriate type and size based on weight specifications not only ensures the longevity and reliability of the installation but also complements the overall effectiveness of the operational environment. For instance, in wastewater treatment plants, selecting a fiberglass grating might initially seem unconventional; however, its corrosion resistance and lower weight contribute to longer service life and reduced maintenance, underscoring the importance of aligning material characteristics with environmental challenges. Moreover, engaging with trusted suppliers who offer comprehensive product data and certifications can significantly affect the outcome of your project. Suppliers providing detailed technical sheets, installation guidance, and customer support underscore the importance of expertise and authority in the selection process, fortifying the trust between supplier and end-user and driving home the necessity of informed purchasing decisions. Ultimately, a deep dive into the weight per square foot of bar grating unravels a world of impactful decisions, each integral to the project’s success. From material science to load analysis, each component weaves into the final fabric of construction excellence, resonating the principles of expertise, authority, and trustworthiness that define the modern landscape of industrial construction and design.

In terms of practical application, industry insiders often turn to standardized load tables and weight charts, tools essential for an accurate analysis of weight per square foot. Engineers and architects can thereby predict how the grating will perform under varying loads, customize grating to fit unique project requirements, and ensure compliance with local building codes and safety regulations. Trustworthy insights from field experts are crucial to navigate the intricacies of selecting the right bar grating. Choosing the appropriate type and size based on weight specifications not only ensures the longevity and reliability of the installation but also complements the overall effectiveness of the operational environment. For instance, in wastewater treatment plants, selecting a fiberglass grating might initially seem unconventional; however, its corrosion resistance and lower weight contribute to longer service life and reduced maintenance, underscoring the importance of aligning material characteristics with environmental challenges. Moreover, engaging with trusted suppliers who offer comprehensive product data and certifications can significantly affect the outcome of your project. Suppliers providing detailed technical sheets, installation guidance, and customer support underscore the importance of expertise and authority in the selection process, fortifying the trust between supplier and end-user and driving home the necessity of informed purchasing decisions. Ultimately, a deep dive into the weight per square foot of bar grating unravels a world of impactful decisions, each integral to the project’s success. From material science to load analysis, each component weaves into the final fabric of construction excellence, resonating the principles of expertise, authority, and trustworthiness that define the modern landscape of industrial construction and design.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024