- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 06:59

Back to list

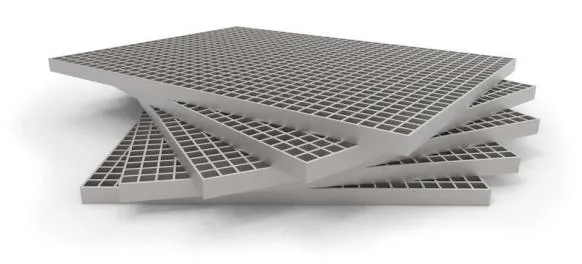

heavy-duty welded bar grating

High-quality bar grating serves an integral role in diverse industrial applications, particularly when it comes to structures requiring durable and load-bearing surfaces. A particular standout in this realm is the 48 wide bar grating, a product engineered for top-notch performance, reliability, and utility across numerous sectors.

Another pivotal aspect relating to trust is the customizability of 48 wide bar grating. Manufacturers offer tailored solutions that align precisely with project specifications, incorporating variables such as load requirement, support structure arrangement, and environmental considerations. This level of customization ensures that users receive a product that not only meets but exceeds specific operational needs. Additionally, the environmental benefits associated with using bar grating reinforce its trust profile. Many manufacturers commit to sustainable processes, offering products made of recycled materials and employing energy-efficient production technologies. Moreover, the lightweight nature of the 48 wide grating eases transportation logistics, reducing carbon footprints related to distribution. The cumulative benefits derived from utilizing 48 wide bar grating articulate a clear narrative for its inclusion in demanding projects. Its remarkable blend of durability, safety, and efficiency makes it a preferred choice for professionals in fields that cannot afford to compromise on any of these aspects. Mastery over its specifications further strengthens one's acumen in project design and implementation, underscoring not only the product's immediate utility but also its pivotal role in long-term structural integrity and economic sustainability. For those embarking on integrating industry-grade grating solutions, a comprehensive understanding coupled with consultative engagement with engineering experts is advisable. Consequently, incorporating 48 wide bar grating into one's project signifies a strategic procurement of quality and assurance, positioning enterprises to harness safety, compliance, and operational success.

Another pivotal aspect relating to trust is the customizability of 48 wide bar grating. Manufacturers offer tailored solutions that align precisely with project specifications, incorporating variables such as load requirement, support structure arrangement, and environmental considerations. This level of customization ensures that users receive a product that not only meets but exceeds specific operational needs. Additionally, the environmental benefits associated with using bar grating reinforce its trust profile. Many manufacturers commit to sustainable processes, offering products made of recycled materials and employing energy-efficient production technologies. Moreover, the lightweight nature of the 48 wide grating eases transportation logistics, reducing carbon footprints related to distribution. The cumulative benefits derived from utilizing 48 wide bar grating articulate a clear narrative for its inclusion in demanding projects. Its remarkable blend of durability, safety, and efficiency makes it a preferred choice for professionals in fields that cannot afford to compromise on any of these aspects. Mastery over its specifications further strengthens one's acumen in project design and implementation, underscoring not only the product's immediate utility but also its pivotal role in long-term structural integrity and economic sustainability. For those embarking on integrating industry-grade grating solutions, a comprehensive understanding coupled with consultative engagement with engineering experts is advisable. Consequently, incorporating 48 wide bar grating into one's project signifies a strategic procurement of quality and assurance, positioning enterprises to harness safety, compliance, and operational success.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024