- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 07:36

Back to list

concrete weight coating

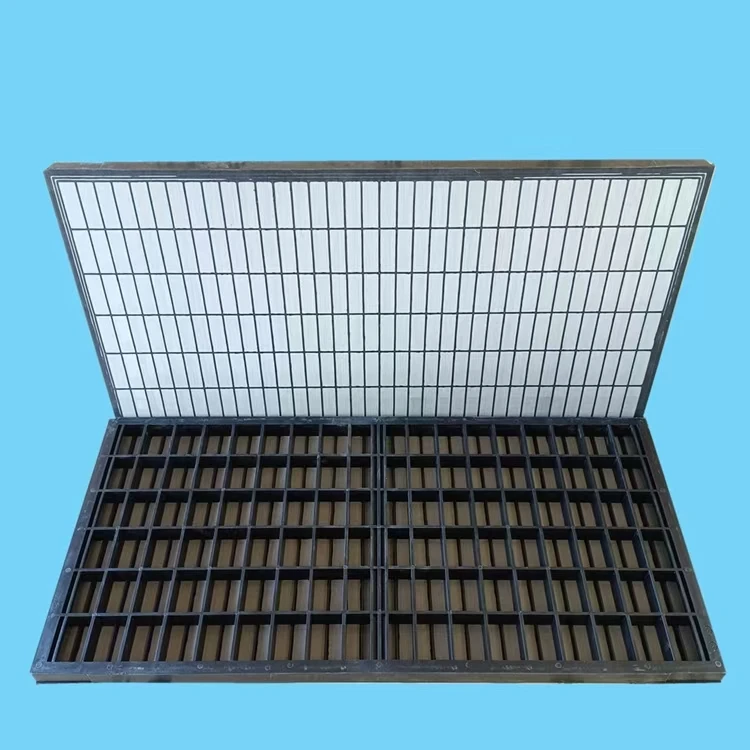

In the realm of industrial flooring solutions, the choice of materials can have a profound impact on efficiency, safety, and long-term durability. Among these solutions, the term grating 32x5 weight is increasingly gaining attention for its unique blend of functionality and structural integrity. This article delves into the specifics of this grating type, providing an authentic analysis of its applications and benefits, guided by industry-leading expertise.

From an engineering perspective, choosing the right grating involves considering several technical parameters – load capacity, span length, and environmental factors. The 32x5 grating is crafted from high-quality materials, often galvanized steel or stainless steel, providing robust resistance to wear and environmental stressors. Its open-grid design promotes ventilation and light penetration, key qualities that experts highlight as indispensable for operational efficiency in industrial environments. Authoritativeness in Structural Engineering Research and industry analyses consistently affirm the 32x5 grating’s compliance with international standards for load-bearing and safety. Endorsed by structural engineers for its load-distribution efficiency, this grating type is frequently used in constructing walkways, platforms, and stair treads in both manufacturing and public infrastructure projects. Its acclaim in professional circles is enhanced by endorsements from regulatory bodies and testing agencies, solidifying its status as a preferred choice in high-stakes applications. Trustworthiness Through Proven Performance Real-world performance data reinforces the credibility of the 32x5 grating as a reliable component of industrial architecture. Case studies from globally recognized firms illustrate the long-term cost savings and enhanced safety outcomes attributable to its installation. Consistent with this, maintenance records show reduced incidence of structural failure, translating to less downtime and overhead costs. Industry testimonials further validate the grating’s robustness, particularly in high-traffic and high-stress environments. Conclusion The grating 32x5 weight represents a strategic merging of engineering precision and practical utility. Its widespread adoption across industries such as manufacturing, petrochemical, and public utilities not only highlights its versatility but also its reliability as a flooring solution. By integrating the dimensions of expert design, authoritative validation, and trustworthy performance, this grating specification is a cardinal example of effective industrial engineering. For stakeholders invested in infrastructure that demands durability, safety, and efficiency, the 32x5 grating remains an unmatched asset.

From an engineering perspective, choosing the right grating involves considering several technical parameters – load capacity, span length, and environmental factors. The 32x5 grating is crafted from high-quality materials, often galvanized steel or stainless steel, providing robust resistance to wear and environmental stressors. Its open-grid design promotes ventilation and light penetration, key qualities that experts highlight as indispensable for operational efficiency in industrial environments. Authoritativeness in Structural Engineering Research and industry analyses consistently affirm the 32x5 grating’s compliance with international standards for load-bearing and safety. Endorsed by structural engineers for its load-distribution efficiency, this grating type is frequently used in constructing walkways, platforms, and stair treads in both manufacturing and public infrastructure projects. Its acclaim in professional circles is enhanced by endorsements from regulatory bodies and testing agencies, solidifying its status as a preferred choice in high-stakes applications. Trustworthiness Through Proven Performance Real-world performance data reinforces the credibility of the 32x5 grating as a reliable component of industrial architecture. Case studies from globally recognized firms illustrate the long-term cost savings and enhanced safety outcomes attributable to its installation. Consistent with this, maintenance records show reduced incidence of structural failure, translating to less downtime and overhead costs. Industry testimonials further validate the grating’s robustness, particularly in high-traffic and high-stress environments. Conclusion The grating 32x5 weight represents a strategic merging of engineering precision and practical utility. Its widespread adoption across industries such as manufacturing, petrochemical, and public utilities not only highlights its versatility but also its reliability as a flooring solution. By integrating the dimensions of expert design, authoritative validation, and trustworthy performance, this grating specification is a cardinal example of effective industrial engineering. For stakeholders invested in infrastructure that demands durability, safety, and efficiency, the 32x5 grating remains an unmatched asset.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024