- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 12:20

Back to list

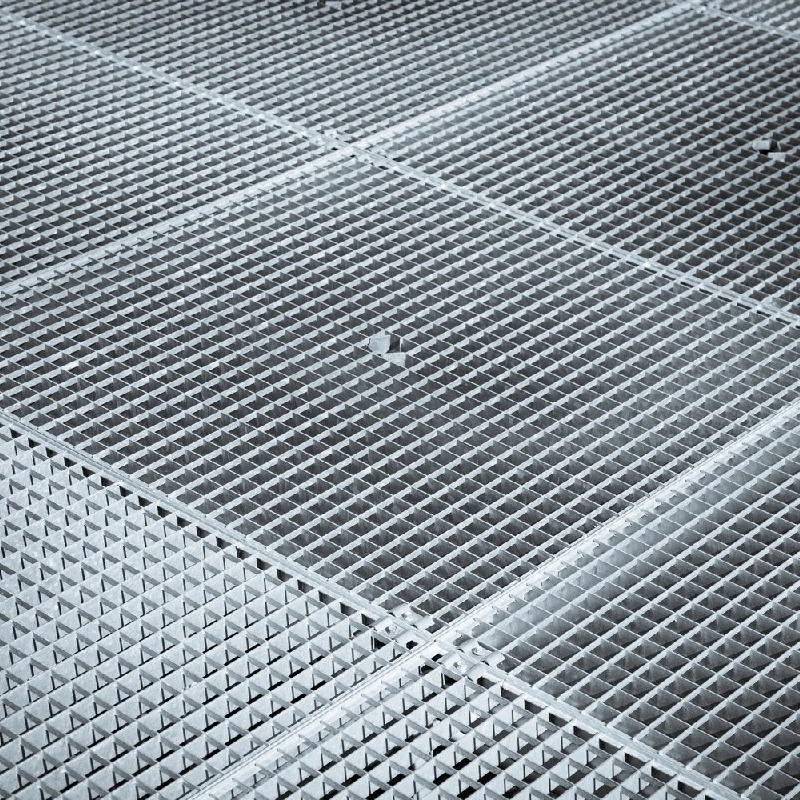

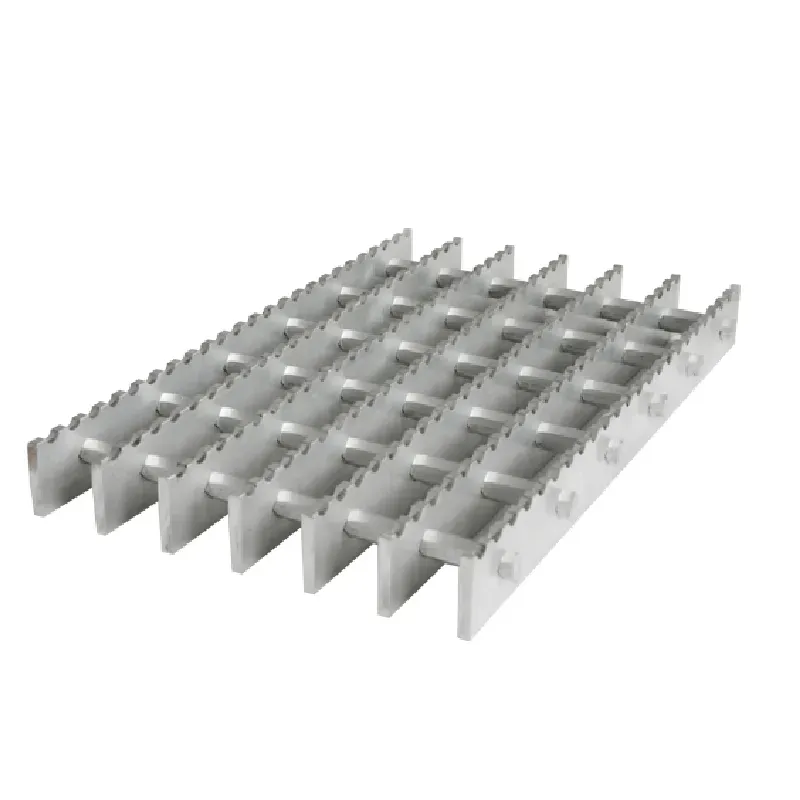

heavy-duty welded bar grating

Bar grating is a pivotal component in numerous industrial and architectural applications, providing a reliable and robust solution for flooring, platforms, and various structural bases. This guide delves into the world of bar grating catalogs, detailing the essential features that make bar gratings indispensable, the variety of options available, and the benefits of sourcing these materials from reputable suppliers.

Navigating a bar grating catalog efficiently is crucial for selecting the product that precisely meets your needs. Detailed product descriptions convey vital characteristics such as bar size, spacing, carrier size, and finish. It's vital to assess each of these aspects with the operational environment in mind. Additionally, consulting the load tables provided within these catalogs can ensure that the chosen grating will perform adequately under planned loads and stresses. The role of a qualified supplier cannot be overstated in the realm of bar grating selection. Reputable suppliers often provide added value through technical support services, professional expertise, and a wide array of customization options. Partnering with an experienced supplier ensures that the selections made are aligned with industry standards and compliance regulations, thereby safeguarding against potential operational failures and safety hazards. In conclusion, bar grating catalogs serve as an indispensable tool for engineers, architects, and procurement professionals aiming to integrate grit-reinforced metal solutions into their projects. By leveraging both expertise and experience, individuals can ensure that the choices they make in bar grating selection are not only optimal for their specific applications but also adhere to the highest standards of quality and safety. As engineers and construction managers continue to seek robust solutions, bar grating remains an efficient and effective choice that combines practicality with resilience across a multitude of environments and applications.

Navigating a bar grating catalog efficiently is crucial for selecting the product that precisely meets your needs. Detailed product descriptions convey vital characteristics such as bar size, spacing, carrier size, and finish. It's vital to assess each of these aspects with the operational environment in mind. Additionally, consulting the load tables provided within these catalogs can ensure that the chosen grating will perform adequately under planned loads and stresses. The role of a qualified supplier cannot be overstated in the realm of bar grating selection. Reputable suppliers often provide added value through technical support services, professional expertise, and a wide array of customization options. Partnering with an experienced supplier ensures that the selections made are aligned with industry standards and compliance regulations, thereby safeguarding against potential operational failures and safety hazards. In conclusion, bar grating catalogs serve as an indispensable tool for engineers, architects, and procurement professionals aiming to integrate grit-reinforced metal solutions into their projects. By leveraging both expertise and experience, individuals can ensure that the choices they make in bar grating selection are not only optimal for their specific applications but also adhere to the highest standards of quality and safety. As engineers and construction managers continue to seek robust solutions, bar grating remains an efficient and effective choice that combines practicality with resilience across a multitude of environments and applications.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024