- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 12:42

Back to list

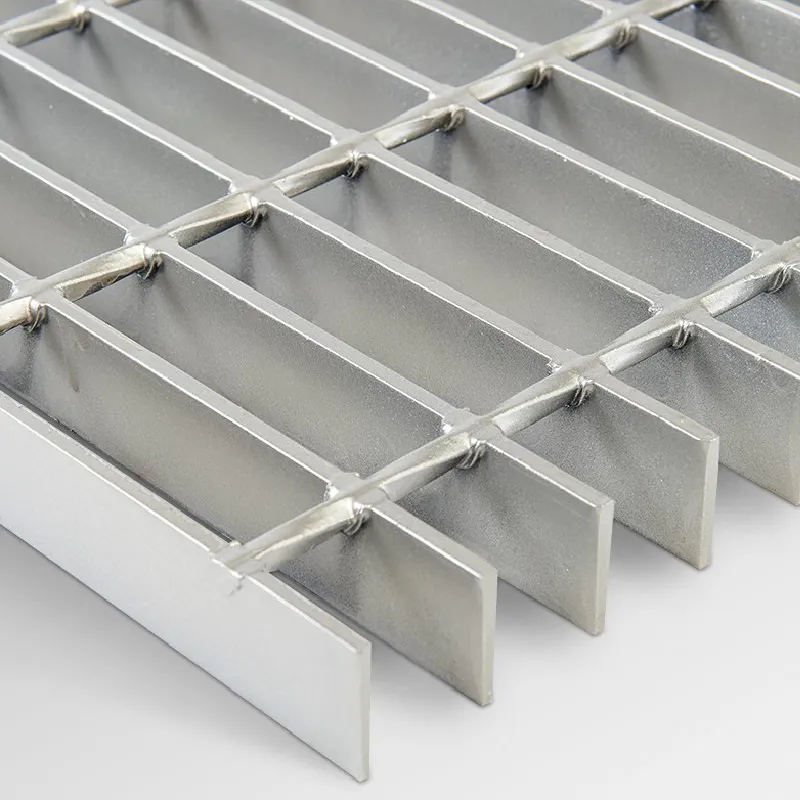

walkway grates

Navigating the intricate world of industrial components often brings us to a fundamental yet underrated element bar grates metal. Their presence is a testament to their structural integrity and functional necessity across various sectors. Not mere utilitarian objects, these grates stand as paragons of engineering efficiency, inviting a closer look into their expansive application and benefits.

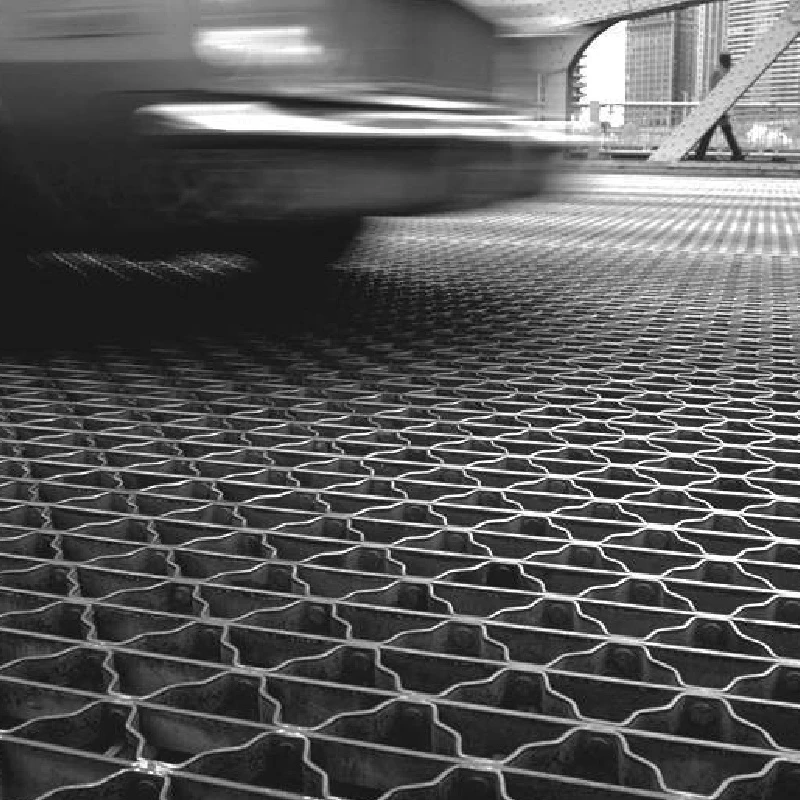

Trustworthiness crowns the value proposition of top-tier bar grates metal providers. They typically offer transparent service agreements, ensuring clients understand the product lifecycles and maintenance expectations. This transparency extends to customer service as well, where queries about product specifics, certifications, and cost-effectiveness are addressed with clarity and honesty, fostering a relationship built on trust and mutual respect. The real-world experience encapsulated in successful applications of bar grates metal further demonstrates their utility and adaptability. For instance, consider an urban setting notorious for its relentless pedestrian and vehicular traffic. Bar grates are skillfully integrated into sidewalks and roadsides, channeling runoff efficiently and reducing the likelihood of flooding after heavy rains. Moreover, in architectural wonderlands such as airports or stadiums, aesthetic adaptations of these metal marvels complement design ethos while providing essential support. Bar grates also find profound use in the green energy sector. Wind turbines, solar farms, and hydroelectric plants are replete with these metallic grids, ensuring not only structural support but also safe and easy access for maintenance crews. This underscores the dynamic role bar grates play in promoting sustainable development goals, further amplifying their essential status in future-forward projects. In conclusion, while bar grates metal might seem like an overlooked component, their inclusion in projects reveals a sophisticated confluence of strength, adaptability, and unyielding reliability. As indispensable connectors in the infrastructure puzzle, they blend engineering precision with practical design, ensuring that safety and function go hand in hand. Those committed to excellence in industrial or architectural projects would do well to regard bar grates metal not just as components, but as partners in progress towards a more secure, efficient, and sustainable built environment.

Trustworthiness crowns the value proposition of top-tier bar grates metal providers. They typically offer transparent service agreements, ensuring clients understand the product lifecycles and maintenance expectations. This transparency extends to customer service as well, where queries about product specifics, certifications, and cost-effectiveness are addressed with clarity and honesty, fostering a relationship built on trust and mutual respect. The real-world experience encapsulated in successful applications of bar grates metal further demonstrates their utility and adaptability. For instance, consider an urban setting notorious for its relentless pedestrian and vehicular traffic. Bar grates are skillfully integrated into sidewalks and roadsides, channeling runoff efficiently and reducing the likelihood of flooding after heavy rains. Moreover, in architectural wonderlands such as airports or stadiums, aesthetic adaptations of these metal marvels complement design ethos while providing essential support. Bar grates also find profound use in the green energy sector. Wind turbines, solar farms, and hydroelectric plants are replete with these metallic grids, ensuring not only structural support but also safe and easy access for maintenance crews. This underscores the dynamic role bar grates play in promoting sustainable development goals, further amplifying their essential status in future-forward projects. In conclusion, while bar grates metal might seem like an overlooked component, their inclusion in projects reveals a sophisticated confluence of strength, adaptability, and unyielding reliability. As indispensable connectors in the infrastructure puzzle, they blend engineering precision with practical design, ensuring that safety and function go hand in hand. Those committed to excellence in industrial or architectural projects would do well to regard bar grates metal not just as components, but as partners in progress towards a more secure, efficient, and sustainable built environment.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024