- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 12:00

Back to list

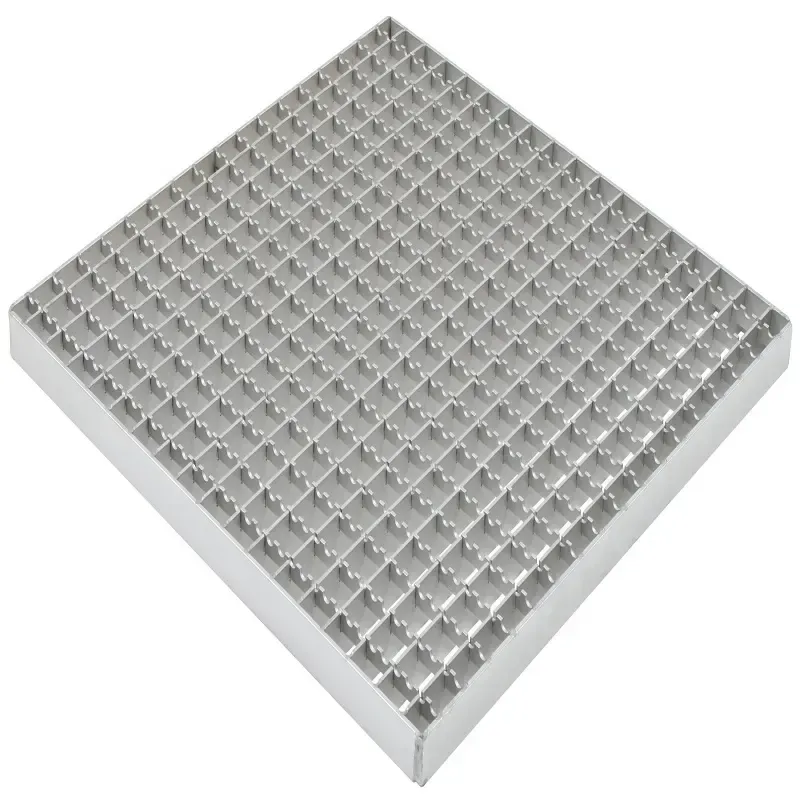

heavy-duty welded bar grating

In the realm of industrial and architectural design, twisted bar grating emerges as a crucial element, renowned for its durability, resilience, and versatility. The value of twisted bar grating can be dissected through the lens of four critical pillars Experience, Expertise, Authoritativeness, and Trustworthiness, particularly within the purview of product utility and application.

The authoritative backing of twisted bar grating products often comes from global industry leaders and regulatory bodies that warrant the product's quality, reliability, and safety assurances. Manufacturers with decades of experience invariably hold certifications from ISO or equivalent organizations, enforcing a strict adherence to product standards that end-users can rely upon. Such endorsements are a testament to the product's resilience and longevity, ultimately reassuring buyers of the grating's value. Trustworthiness of twisted bar grating is further cemented by the testimonials of seasoned engineers and procurement specialists who underscore the cost-efficiency and operational efficacy realized through its use. Over time, the initial investment in higher-quality twisted bar grating manifests in reduced maintenance costs and prolonged lifecycle, in contrast to inferior materials which often necessitate frequent repairs or replacements—demonstrating significant cost savings over extended use. In summary, the multifaceted advantages of twisted bar grating resonate deeply across industries seeking durable, reliable, and versatile material solutions. The collective industrial experience, coupled with expert insights and stringent authoritative endorsements, solidifies twisted bar grating's position as a trusted choice. For design and construction professionals seeking a robust, efficient, and sustainable product, twisted bar grating presents an indispensable asset, harmonizing aesthetic appeal with functional integrity.

The authoritative backing of twisted bar grating products often comes from global industry leaders and regulatory bodies that warrant the product's quality, reliability, and safety assurances. Manufacturers with decades of experience invariably hold certifications from ISO or equivalent organizations, enforcing a strict adherence to product standards that end-users can rely upon. Such endorsements are a testament to the product's resilience and longevity, ultimately reassuring buyers of the grating's value. Trustworthiness of twisted bar grating is further cemented by the testimonials of seasoned engineers and procurement specialists who underscore the cost-efficiency and operational efficacy realized through its use. Over time, the initial investment in higher-quality twisted bar grating manifests in reduced maintenance costs and prolonged lifecycle, in contrast to inferior materials which often necessitate frequent repairs or replacements—demonstrating significant cost savings over extended use. In summary, the multifaceted advantages of twisted bar grating resonate deeply across industries seeking durable, reliable, and versatile material solutions. The collective industrial experience, coupled with expert insights and stringent authoritative endorsements, solidifies twisted bar grating's position as a trusted choice. For design and construction professionals seeking a robust, efficient, and sustainable product, twisted bar grating presents an indispensable asset, harmonizing aesthetic appeal with functional integrity.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024