- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 05:44

Back to list

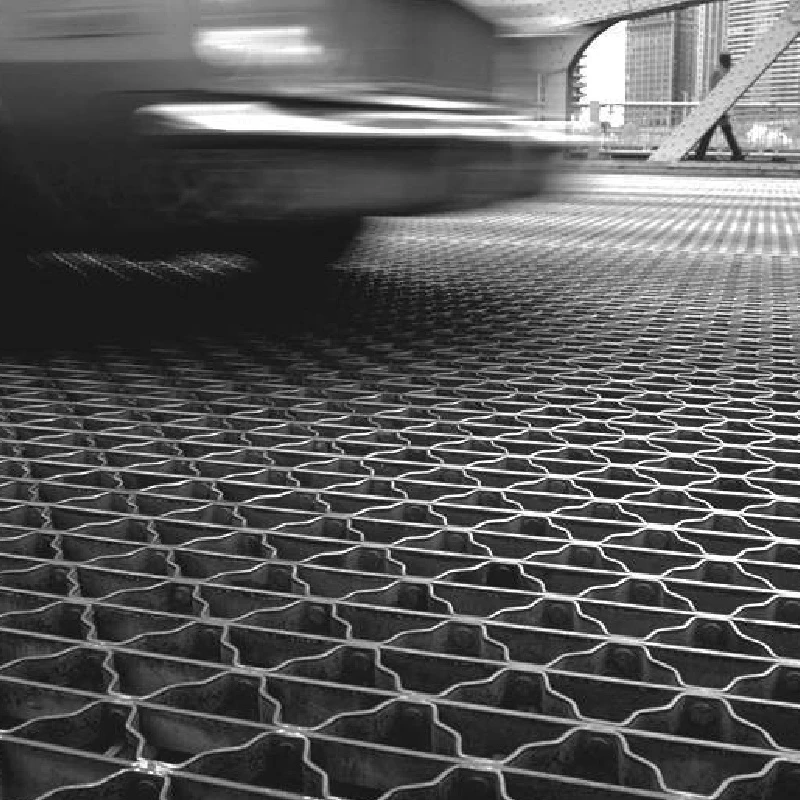

Welded Steel Grating

For industry professionals seeking innovative solutions for structural applications, welded bar grating emerges as an unparalleled choice. This product has gained significant traction across multiple sectors due to its robustness, versatility, and cost-effectiveness.

Safety is not compromised with the use of welded bar grating. The surface design includes arrays that provide excellent grip, preventing slips and falls—a crucial factor in workplace safety. It's often utilized where ventilation and light passage are required, such as in mezzanines or elevated walkways, merging safety with functionality effectively. Moreover, welded bar grating supports sustainable building practices. Steel is highly recyclable, which aligns with environmental goals and standards. Choosing this material contributes to a circular economy, making it an eco-conscious choice for environmentally aware industries. In terms of authority and trustworthiness, the consistent performance of welded bar grating has been documented across numerous high-stakes installations. Leading architects and construction experts endorse its use due to its track record of reliability and efficiency. Many industry certifications back its quality, setting a benchmark for standards in construction materials. To ensure the highest level of expertise when selecting welded bar grating, engagement with knowledgeable suppliers and manufacturers is recommended. These professionals provide valuable insights into which specifications meet industry standards and project needs. They can guide you through options in finishes and fabrication methods to optimize the benefits of your grating solution. In conclusion, welded bar grating stands out as a superior construction material attributed to its strength, adaptability, and durability. Its applicability across diverse industrial scenarios underscores its value, while its low maintenance and high safety features render it an indispensable asset in modern engineering and construction projects. From initial selection to installation and long-term maintenance, welded bar grating represents a choice rooted in reliability, economy, and enduring performance.

Safety is not compromised with the use of welded bar grating. The surface design includes arrays that provide excellent grip, preventing slips and falls—a crucial factor in workplace safety. It's often utilized where ventilation and light passage are required, such as in mezzanines or elevated walkways, merging safety with functionality effectively. Moreover, welded bar grating supports sustainable building practices. Steel is highly recyclable, which aligns with environmental goals and standards. Choosing this material contributes to a circular economy, making it an eco-conscious choice for environmentally aware industries. In terms of authority and trustworthiness, the consistent performance of welded bar grating has been documented across numerous high-stakes installations. Leading architects and construction experts endorse its use due to its track record of reliability and efficiency. Many industry certifications back its quality, setting a benchmark for standards in construction materials. To ensure the highest level of expertise when selecting welded bar grating, engagement with knowledgeable suppliers and manufacturers is recommended. These professionals provide valuable insights into which specifications meet industry standards and project needs. They can guide you through options in finishes and fabrication methods to optimize the benefits of your grating solution. In conclusion, welded bar grating stands out as a superior construction material attributed to its strength, adaptability, and durability. Its applicability across diverse industrial scenarios underscores its value, while its low maintenance and high safety features render it an indispensable asset in modern engineering and construction projects. From initial selection to installation and long-term maintenance, welded bar grating represents a choice rooted in reliability, economy, and enduring performance.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024