- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 19, 2025 00:32

Back to list

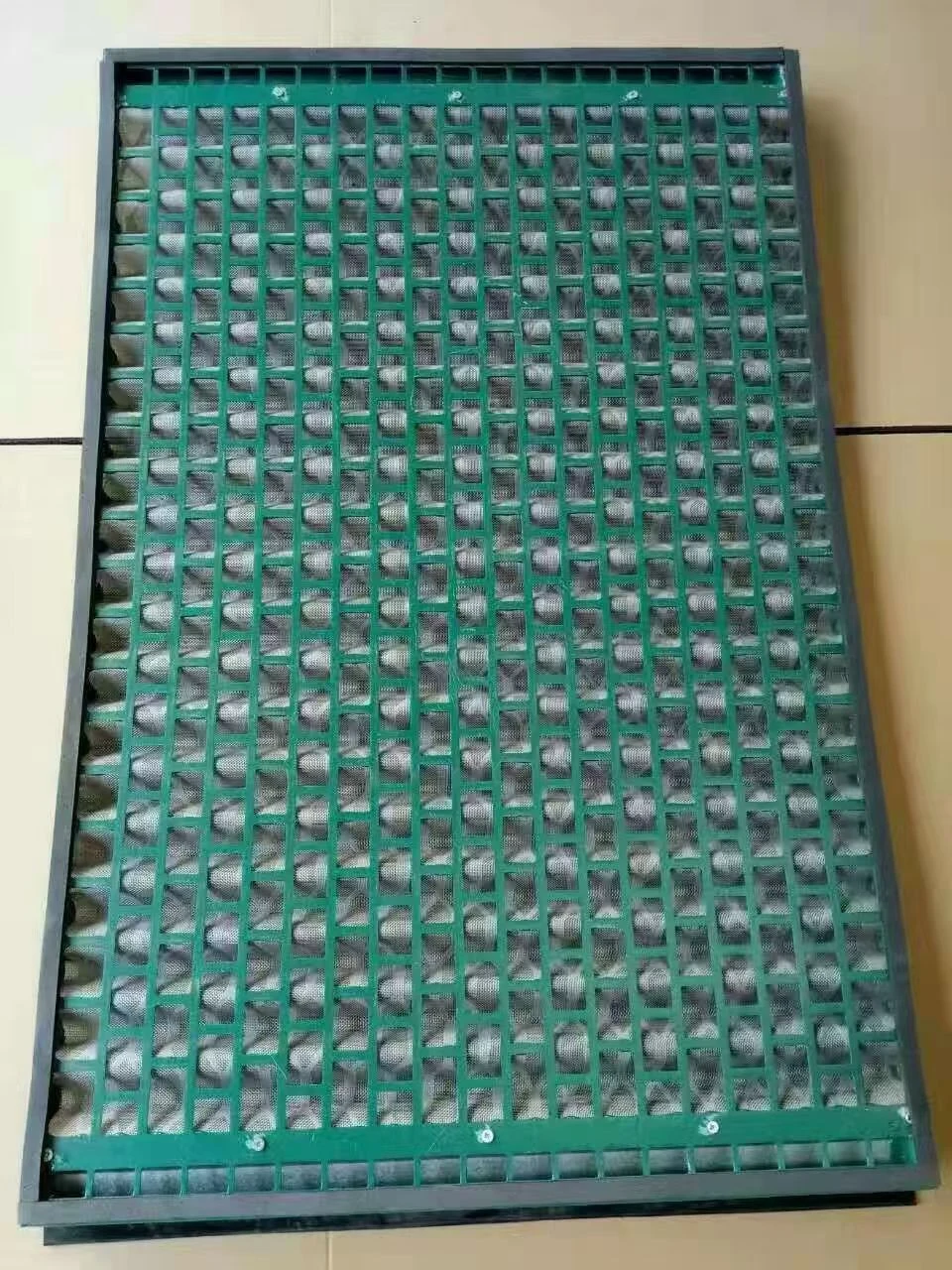

heavy-duty welded bar grating

Heavy-duty welded bar grating is an indispensable component in numerous industrial applications, providing both functionality and safety in areas requiring robust structural support. Its prominent use in construction, manufacturing, and warehousing demonstrates its integral role in these sectors. Here’s an in-depth exploration of heavy-duty welded bar grating that leverages the four SEO content pillars of experience, expertise, authoritativeness, and trustworthiness to ensure a distinctive article that stands out in Google search results.

From a practical standpoint, the versatility of heavy-duty welded bar grating cannot be overstated. Whether used in flooring, mezzanines, platforms, or walkways, it allows for sunlight, ventilation, and debris passage, an essential feature in maintaining a healthy environment within factories and warehouses. Additionally, its anti-slip surface is pivotal in preventing accidents, thereby boosting workplace safety—a primary concern for all industrial operations. Furthermore, the affordability and recyclability of these gratings make them a sustainable option for forward-thinking businesses aiming to reduce their environmental impact. Heavy-duty welded bar grating can be repurposed, significantly reducing waste. An often overlooked but valuable trait of heavy-duty welded bar grating is its adaptability to custom specifications, enabling it to effortlessly integrate into unique architectural and engineering designs. Heavy-duty welded bar grating, therefore, emerges not merely as an industrial commodity but as a pivotal element in infrastructure that promotes efficiency, safety, and sustainability. For those seeking robust solutions, investing in quality grating backed by solid experience and expertise remains a wise decision that pays dividends in both functionality and safety. By selecting high-grade products from a reputable supplier, stakeholders ensure not only compliance with industry standards but also a commitment to excellence, thus maximizing the utility and lifespan of heavy-duty welded bar grating in a myriad of applications.

From a practical standpoint, the versatility of heavy-duty welded bar grating cannot be overstated. Whether used in flooring, mezzanines, platforms, or walkways, it allows for sunlight, ventilation, and debris passage, an essential feature in maintaining a healthy environment within factories and warehouses. Additionally, its anti-slip surface is pivotal in preventing accidents, thereby boosting workplace safety—a primary concern for all industrial operations. Furthermore, the affordability and recyclability of these gratings make them a sustainable option for forward-thinking businesses aiming to reduce their environmental impact. Heavy-duty welded bar grating can be repurposed, significantly reducing waste. An often overlooked but valuable trait of heavy-duty welded bar grating is its adaptability to custom specifications, enabling it to effortlessly integrate into unique architectural and engineering designs. Heavy-duty welded bar grating, therefore, emerges not merely as an industrial commodity but as a pivotal element in infrastructure that promotes efficiency, safety, and sustainability. For those seeking robust solutions, investing in quality grating backed by solid experience and expertise remains a wise decision that pays dividends in both functionality and safety. By selecting high-grade products from a reputable supplier, stakeholders ensure not only compliance with industry standards but also a commitment to excellence, thus maximizing the utility and lifespan of heavy-duty welded bar grating in a myriad of applications.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024