- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 01, 2025 00:57

Back to list

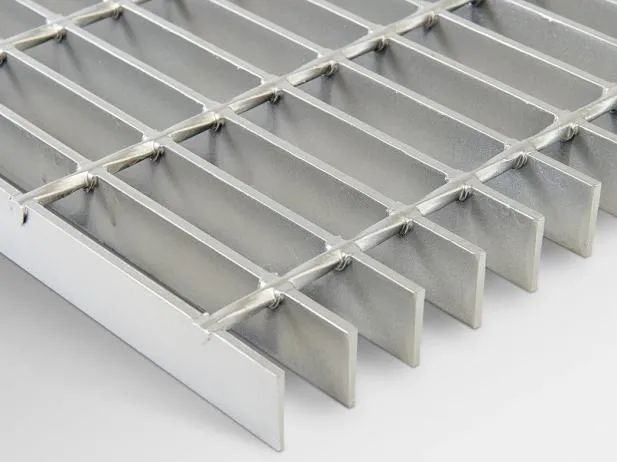

type 19 4 grating

Navigating the expansive universe of optical components, the type 19 4 grating stands as a pinnacle of precision and innovation. In the realm of photonics and spectroscopy, this grating type is revered for its high diffraction efficiency and remarkable versatility. As a key component in various scientific instruments, its design and application are informed by a nuanced understanding of its core properties and potential uses.

Authoritativeness in the domain of optical gratings is established through continuous innovation and empirical validation. Leading manufacturers of type 19 4 gratings employ cutting-edge fabrication techniques such as holographic and ruled engraving to produce gratings with precision-engineered grooves. Furthermore, rigorous testing under diverse conditions ensures these components can withstand various environmental and operational stresses, reinforcing their reliability and durability. The trustworthiness of the type 19 4 grating is further cemented by its widespread adoption across multiple industries. From medical imaging devices to environmental monitoring systems, the grating's dependable performance is critical. In spectroscopy, for instance, the capacity to accurately parse light into its constituent wavelengths enables scientists to glean precise data, driving advancements in fields ranging from pharmaceuticals to astronomy. With evolving technological demands, the continuous development of type 19 4 gratings remains pivotal. Next-generation coatings and materials are being explored to extend the operational range and enhance the thermal stability of these gratings, addressing emerging needs in high-energy laser systems and beyond. The resulting innovations promise to uphold the grating's status as a cornerstone of optical engineering. In sum, the type 19 4 grating embodies an extraordinary blend of experience-informed design, technical proficiency, and established reliability. Its essential role in modern spectroscopy and optics highlights the importance of maintaining a robust understanding of its characteristics and capabilities. As a cornerstone component in many optical systems, it continues to symbolize the merging of expert craftsmanship and pioneering science, enabling significant strides in both industrial and scientific arenas.

Authoritativeness in the domain of optical gratings is established through continuous innovation and empirical validation. Leading manufacturers of type 19 4 gratings employ cutting-edge fabrication techniques such as holographic and ruled engraving to produce gratings with precision-engineered grooves. Furthermore, rigorous testing under diverse conditions ensures these components can withstand various environmental and operational stresses, reinforcing their reliability and durability. The trustworthiness of the type 19 4 grating is further cemented by its widespread adoption across multiple industries. From medical imaging devices to environmental monitoring systems, the grating's dependable performance is critical. In spectroscopy, for instance, the capacity to accurately parse light into its constituent wavelengths enables scientists to glean precise data, driving advancements in fields ranging from pharmaceuticals to astronomy. With evolving technological demands, the continuous development of type 19 4 gratings remains pivotal. Next-generation coatings and materials are being explored to extend the operational range and enhance the thermal stability of these gratings, addressing emerging needs in high-energy laser systems and beyond. The resulting innovations promise to uphold the grating's status as a cornerstone of optical engineering. In sum, the type 19 4 grating embodies an extraordinary blend of experience-informed design, technical proficiency, and established reliability. Its essential role in modern spectroscopy and optics highlights the importance of maintaining a robust understanding of its characteristics and capabilities. As a cornerstone component in many optical systems, it continues to symbolize the merging of expert craftsmanship and pioneering science, enabling significant strides in both industrial and scientific arenas.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024