- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 06, 2025 04:23

Back to list

derrick shaker screens

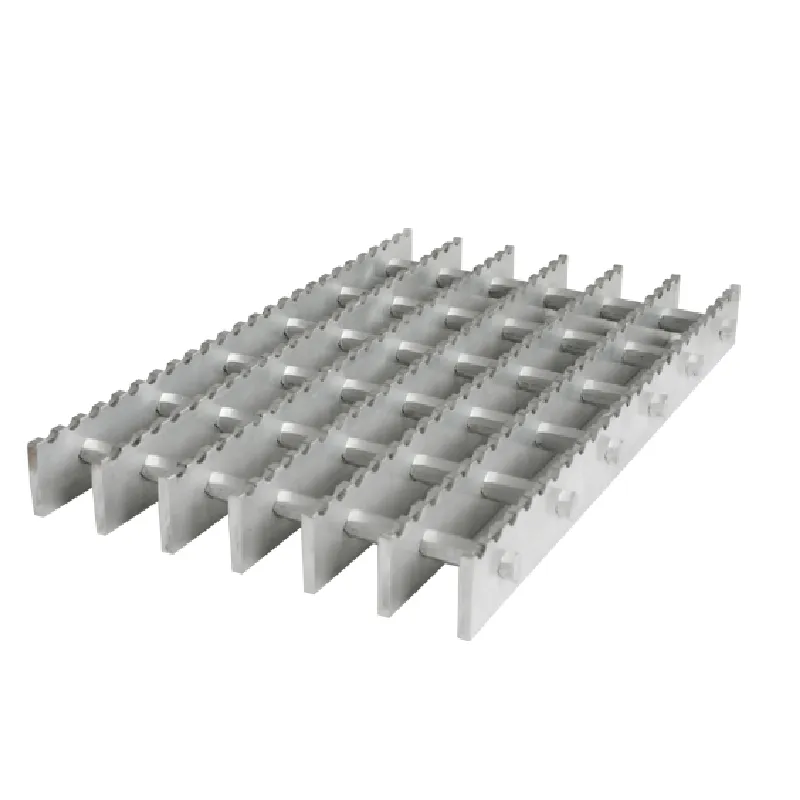

Choosing the right trench drain grate sizes is a critical step in ensuring effective drainage solutions for both residential and commercial projects. This decision impacts not only the functionality but also the safety and aesthetics of the drainage system. Leveraging years of industry expertise, we delve into the nuances of selecting trench drain grate sizes, offering insights that blend technical precision with real-world application.

A well-sized trench drain grate contributes significantly to the aesthetics of a project. Architectural preferences often dictate the need for customizing grate size and pattern to meet the specific visual or functional objectives of a project. Appropriately sized grates blended with aesthetically pleasing designs can complement paved surfaces and enhance overall site appearance without compromising performance. Industry expertise underscores the necessity of adhering to stringent compliance standards when selecting trench drain grates. Compliance with standards such as EN1433 or ASTM ensures that grates meet safety, performance, and longevity specifications. These standards define acceptable ranges for water intake capacity, load ratings, and surface conditions. Professionals must ensure selected grates are certified to avoid potential liabilities or failures. Track record and expert recommendations can further guide the selection process. Engaging with manufacturers renowned for their quality assurance and innovative designs can simplify decision-making. They can offer bespoke solutions tailored to specific project demands and provide warranties that add a layer of trust and reliability, crucial in large scale or public infrastructure projects. Ultimately, selecting the right trench drain grate size involves a delicate balance between technical requirements and aesthetic aspirations, guided by expertise and a commitment to standards. When done correctly, this process ensures that drainage systems are safe, functional, and visually cohesive, providing lasting value and performance. For those in the planning and implementation stages of drainage projects, consulting with industry experts and reviewing technical guidelines can provide invaluable insight, significantly contributing to the success and sustainability of the installation.

A well-sized trench drain grate contributes significantly to the aesthetics of a project. Architectural preferences often dictate the need for customizing grate size and pattern to meet the specific visual or functional objectives of a project. Appropriately sized grates blended with aesthetically pleasing designs can complement paved surfaces and enhance overall site appearance without compromising performance. Industry expertise underscores the necessity of adhering to stringent compliance standards when selecting trench drain grates. Compliance with standards such as EN1433 or ASTM ensures that grates meet safety, performance, and longevity specifications. These standards define acceptable ranges for water intake capacity, load ratings, and surface conditions. Professionals must ensure selected grates are certified to avoid potential liabilities or failures. Track record and expert recommendations can further guide the selection process. Engaging with manufacturers renowned for their quality assurance and innovative designs can simplify decision-making. They can offer bespoke solutions tailored to specific project demands and provide warranties that add a layer of trust and reliability, crucial in large scale or public infrastructure projects. Ultimately, selecting the right trench drain grate size involves a delicate balance between technical requirements and aesthetic aspirations, guided by expertise and a commitment to standards. When done correctly, this process ensures that drainage systems are safe, functional, and visually cohesive, providing lasting value and performance. For those in the planning and implementation stages of drainage projects, consulting with industry experts and reviewing technical guidelines can provide invaluable insight, significantly contributing to the success and sustainability of the installation.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024