- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 26, 2025 04:24

Back to list

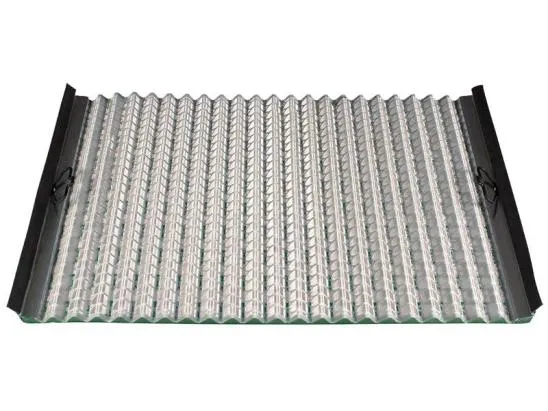

swage locked grating

Swage locked grating, known for its robust construction and versatile applications, stands out as a pivotal component in industrial, commercial, and architectural sectors. This construction element, sought for its durability and safety, embodies a unique mesh design that enhances facility efficiency and worker protection. In a world where infrastructure reliability and safety are paramount, swage locked grating offers an innovative solution that meets and often exceeds industry demands.

Moreover, swage locked grating's versatility adds to its appeal. It can be custom-manufactured to meet specific dimensions and load requirements, offering bespoke solutions for complex projects. This adaptability ensures that the grating can be integrated into existing infrastructures or new constructions with minimal modification, thereby reducing installation time and costs. Incorporating swage locked grating into a project is an investment in quality and longevity. Its low maintenance needs and resilient structure mean that once installed, it requires minimal oversight, providing peace of mind to facility managers. This characteristic is particularly valuable in remote or high-stakes environments where unscheduled maintenance can be costly and hazardous. Furthermore, swage locked grating supports environmental sustainability efforts. Many manufacturers prioritize eco-friendly production processes and materials, ensuring that the grating is not only effective but also environmentally responsible. The recyclability of its primary materials—steel and aluminum—aligns with global sustainability goals, reducing waste and promoting resource efficiency. Ultimately, swage locked grating represents the zenith of modern engineering solutions, marrying practicality with performance. Its presence in critical infrastructure speaks to its importance and reliability, making it an indispensable asset in building safe, efficient, and durable environments. By choosing swage locked grating, industries not only adhere to best practices in safety and efficiency but also pave the way for future innovation in structural components.

Moreover, swage locked grating's versatility adds to its appeal. It can be custom-manufactured to meet specific dimensions and load requirements, offering bespoke solutions for complex projects. This adaptability ensures that the grating can be integrated into existing infrastructures or new constructions with minimal modification, thereby reducing installation time and costs. Incorporating swage locked grating into a project is an investment in quality and longevity. Its low maintenance needs and resilient structure mean that once installed, it requires minimal oversight, providing peace of mind to facility managers. This characteristic is particularly valuable in remote or high-stakes environments where unscheduled maintenance can be costly and hazardous. Furthermore, swage locked grating supports environmental sustainability efforts. Many manufacturers prioritize eco-friendly production processes and materials, ensuring that the grating is not only effective but also environmentally responsible. The recyclability of its primary materials—steel and aluminum—aligns with global sustainability goals, reducing waste and promoting resource efficiency. Ultimately, swage locked grating represents the zenith of modern engineering solutions, marrying practicality with performance. Its presence in critical infrastructure speaks to its importance and reliability, making it an indispensable asset in building safe, efficient, and durable environments. By choosing swage locked grating, industries not only adhere to best practices in safety and efficiency but also pave the way for future innovation in structural components.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024