- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 07:47

Back to list

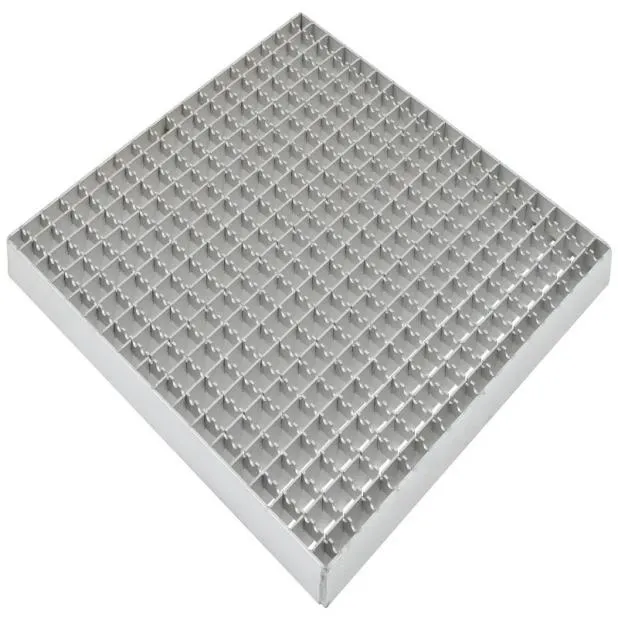

steel walkway grating prices

Navigating the landscape of steel walkway grating prices requires a keen understanding of the market dynamics, material specifications, and the factors that influence cost fluctuations. As an industry professional with years of hands-on experience in the field, I aim to shed light on these critical components to aid businesses and construction managers in making informed purchasing decisions.

Another vital factor influencing the price of steel walkway grating is the size and thickness of the bar and mesh. Grating with thicker bars and smaller mesh sizes typically costs more due to increased material usage and manufacturing complexity. Buyers need to consider the load requirements and the specific application environment to select the appropriate specifications that balance performance and price. Market trends and global steel prices further contribute to the fluctuating costs of steel grating. Global events, such as fluctuations in raw material availability, trade policies, and economic conditions in major steel-producing countries, can directly impact prices. For instance, recent global supply chain disruptions have led to significant price volatility in steel products, including walkway grating. Buyers must stay informed about these trends to time their purchases advantageously. Finally, the supplier’s expertise and reputation can influence pricing. Suppliers with a long-standing presence in the market tend to have more reliable quality controls and customer service, which can justify a slightly higher cost. Such suppliers often offer additional services, such as customized designs, installation guidance, and safety certifications, thereby providing added value beyond the base price of the grating. In conclusion, understanding the nuances of steel walkway grating prices goes beyond just comparing costs. It requires a comprehensive analysis of material types, manufacturing processes, specification needs, market conditions, and supplier reliability. By considering these factors thoughtfully, businesses can make strategic decisions that not only fit their budget but also ensure safety and reliability in their infrastructure projects. Buyers who approach the market with this expertise are better equipped to select the right product at the best possible price, ensuring long-term satisfaction and performance.

Another vital factor influencing the price of steel walkway grating is the size and thickness of the bar and mesh. Grating with thicker bars and smaller mesh sizes typically costs more due to increased material usage and manufacturing complexity. Buyers need to consider the load requirements and the specific application environment to select the appropriate specifications that balance performance and price. Market trends and global steel prices further contribute to the fluctuating costs of steel grating. Global events, such as fluctuations in raw material availability, trade policies, and economic conditions in major steel-producing countries, can directly impact prices. For instance, recent global supply chain disruptions have led to significant price volatility in steel products, including walkway grating. Buyers must stay informed about these trends to time their purchases advantageously. Finally, the supplier’s expertise and reputation can influence pricing. Suppliers with a long-standing presence in the market tend to have more reliable quality controls and customer service, which can justify a slightly higher cost. Such suppliers often offer additional services, such as customized designs, installation guidance, and safety certifications, thereby providing added value beyond the base price of the grating. In conclusion, understanding the nuances of steel walkway grating prices goes beyond just comparing costs. It requires a comprehensive analysis of material types, manufacturing processes, specification needs, market conditions, and supplier reliability. By considering these factors thoughtfully, businesses can make strategic decisions that not only fit their budget but also ensure safety and reliability in their infrastructure projects. Buyers who approach the market with this expertise are better equipped to select the right product at the best possible price, ensuring long-term satisfaction and performance.

Share

Latest news

-

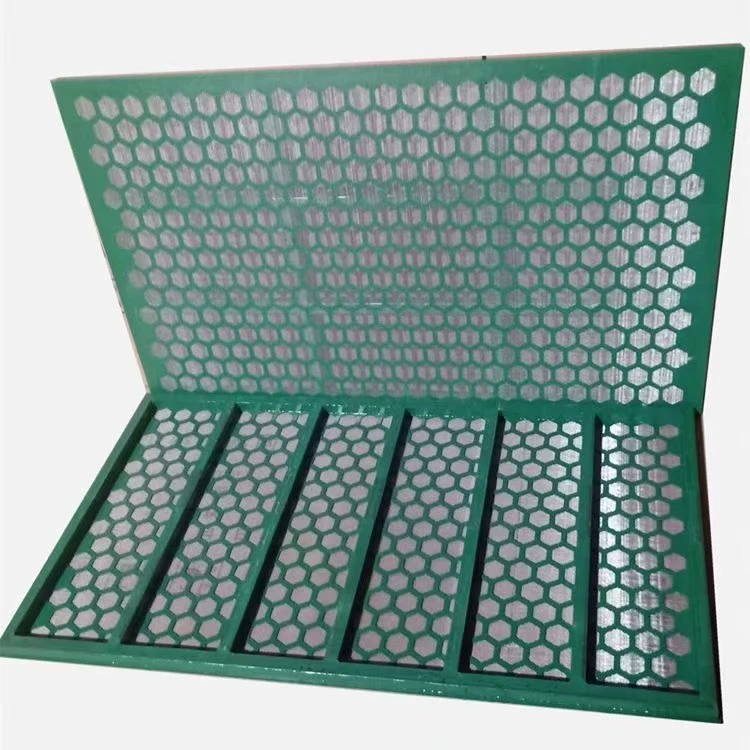

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024