- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 29, 2025 04:45

Back to list

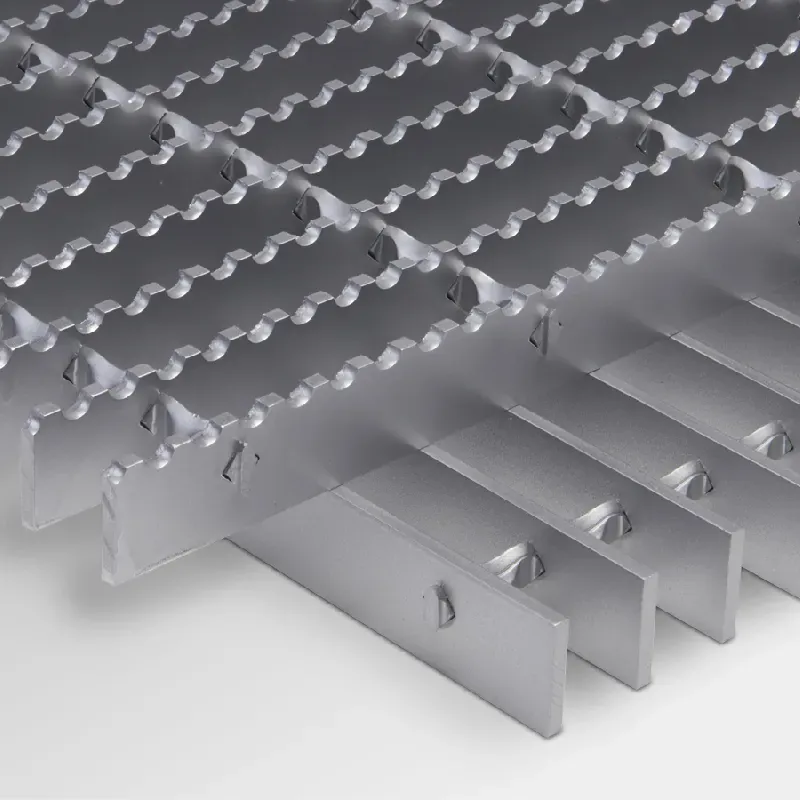

Steel Grating

Steel metal grating continues to be a pivotal asset in various industrial applications, known for its robustness and versatility. For those in manufacturing, construction, or any sector demanding formidable flooring solutions, steel metal grating is often the go-to choice. This piece explores the distinctive characteristics and extensive benefits of steel metal grating, making it a premier solution for businesses worldwide.

Trustworthiness is an essential element, particularly when it comes to safety. Steel metal grating’s slip-resistant surface enhances workplace safety, significantly reducing the risk of accidents, which is crucial in hazardous environments such as oil refineries or power plants. Reputable suppliers often provide extensive documentation and testing results, offering transparency into the product's performance metrics under real-world conditions. Moreover, the environmental impact of manufacturing processes today is under intense scrutiny. The recyclability of steel metal grating aligns it with sustainable practices, reducing industrial waste. Many companies are now investing in methods to make production processes more eco-friendly, thus reinforcing steel grating's reputation as a responsible choice for environmentally-conscious enterprises. In conclusion, steel metal grating distinguishes itself as an unmatched, reliable solution across various industrial sectors. Its historical pedigree and evolving innovations mirror a product that consistently meets the high demands for strength, safety, and sustainability in modern industries. Businesses choosing to integrate steel metal grating are not only investing in a proven product but are also aligning themselves with a legacy of engineering excellence and environmental responsibility.

Trustworthiness is an essential element, particularly when it comes to safety. Steel metal grating’s slip-resistant surface enhances workplace safety, significantly reducing the risk of accidents, which is crucial in hazardous environments such as oil refineries or power plants. Reputable suppliers often provide extensive documentation and testing results, offering transparency into the product's performance metrics under real-world conditions. Moreover, the environmental impact of manufacturing processes today is under intense scrutiny. The recyclability of steel metal grating aligns it with sustainable practices, reducing industrial waste. Many companies are now investing in methods to make production processes more eco-friendly, thus reinforcing steel grating's reputation as a responsible choice for environmentally-conscious enterprises. In conclusion, steel metal grating distinguishes itself as an unmatched, reliable solution across various industrial sectors. Its historical pedigree and evolving innovations mirror a product that consistently meets the high demands for strength, safety, and sustainability in modern industries. Businesses choosing to integrate steel metal grating are not only investing in a proven product but are also aligning themselves with a legacy of engineering excellence and environmental responsibility.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024