- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 08:33

Back to list

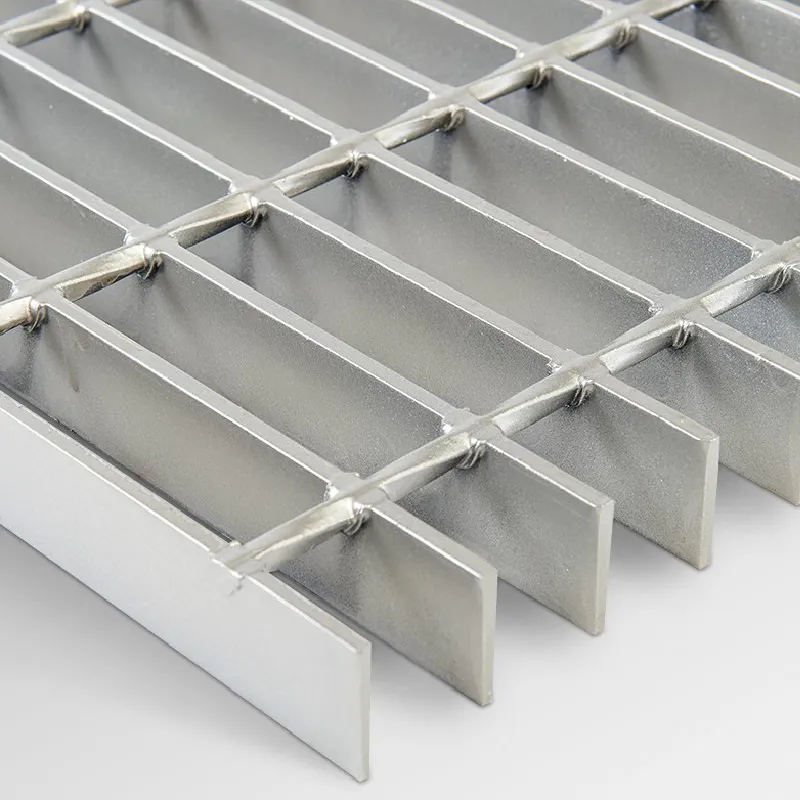

steel grating price

Steel grating, a vital component in construction and industrial applications, has seen dynamic shifts in pricing influenced by multiple factors. In recent years, sector experts and consumers alike have experienced varying trends in steel grating prices, driven by material costs, demand, and logistical factors.

Furthermore, environmental policies and sustainability concerns affect production costs and, by extension, pricing. Steel manufacturing is energy-intensive, and with the global push towards greener practices, companies are investing more in eco-friendly technologies. While these initiatives are critical for long-term sustainability, they can initially lead to cost increases that are reflected in steel grating prices. Expertise in market analytics plays a pivotal role for consumers looking to navigate these price landscapes. Industry forecasts and trend analysis, often accessible through specialized consultancies, provide invaluable insights. Knowing when to buy can lead to significant cost savings, and having authoritative sources offering market predictions enhances the credibility and decision-making capabilities of buyers and project managers. The pricing of steel grating is also influenced by design characteristics such as the type of material finish, mesh size, and load-bearing capabilities. Projects requiring bespoke grating solutions may incur additional costs due to custom manufacturing processes. These aspects need thorough examination by professionals to ensure the best value for high performance. Industry professionals stress the importance of building trust with reliable suppliers to mitigate price volatility risks. Trustworthy suppliers offer transparency in pricing models and often provide detailed breakdowns of costs. Establishing robust relationships ensures long-term supply stability and the possibility of negotiating price benefits. In summary, understanding the steel grating market requires comprehensive knowledge across several domains material costs, global demand, technological advancements, and environmental impacts. Integrating real-time data analysis with professional expertise ensures a strategic approach to purchasing, setting a foundation for cost-effective and high-quality project outcomes. For businesses and professionals involved in sectors relying heavily on steel grating, staying informed about these factors is paramount for sustaining competitive advantage.

Furthermore, environmental policies and sustainability concerns affect production costs and, by extension, pricing. Steel manufacturing is energy-intensive, and with the global push towards greener practices, companies are investing more in eco-friendly technologies. While these initiatives are critical for long-term sustainability, they can initially lead to cost increases that are reflected in steel grating prices. Expertise in market analytics plays a pivotal role for consumers looking to navigate these price landscapes. Industry forecasts and trend analysis, often accessible through specialized consultancies, provide invaluable insights. Knowing when to buy can lead to significant cost savings, and having authoritative sources offering market predictions enhances the credibility and decision-making capabilities of buyers and project managers. The pricing of steel grating is also influenced by design characteristics such as the type of material finish, mesh size, and load-bearing capabilities. Projects requiring bespoke grating solutions may incur additional costs due to custom manufacturing processes. These aspects need thorough examination by professionals to ensure the best value for high performance. Industry professionals stress the importance of building trust with reliable suppliers to mitigate price volatility risks. Trustworthy suppliers offer transparency in pricing models and often provide detailed breakdowns of costs. Establishing robust relationships ensures long-term supply stability and the possibility of negotiating price benefits. In summary, understanding the steel grating market requires comprehensive knowledge across several domains material costs, global demand, technological advancements, and environmental impacts. Integrating real-time data analysis with professional expertise ensures a strategic approach to purchasing, setting a foundation for cost-effective and high-quality project outcomes. For businesses and professionals involved in sectors relying heavily on steel grating, staying informed about these factors is paramount for sustaining competitive advantage.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024