- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 07:57

Back to list

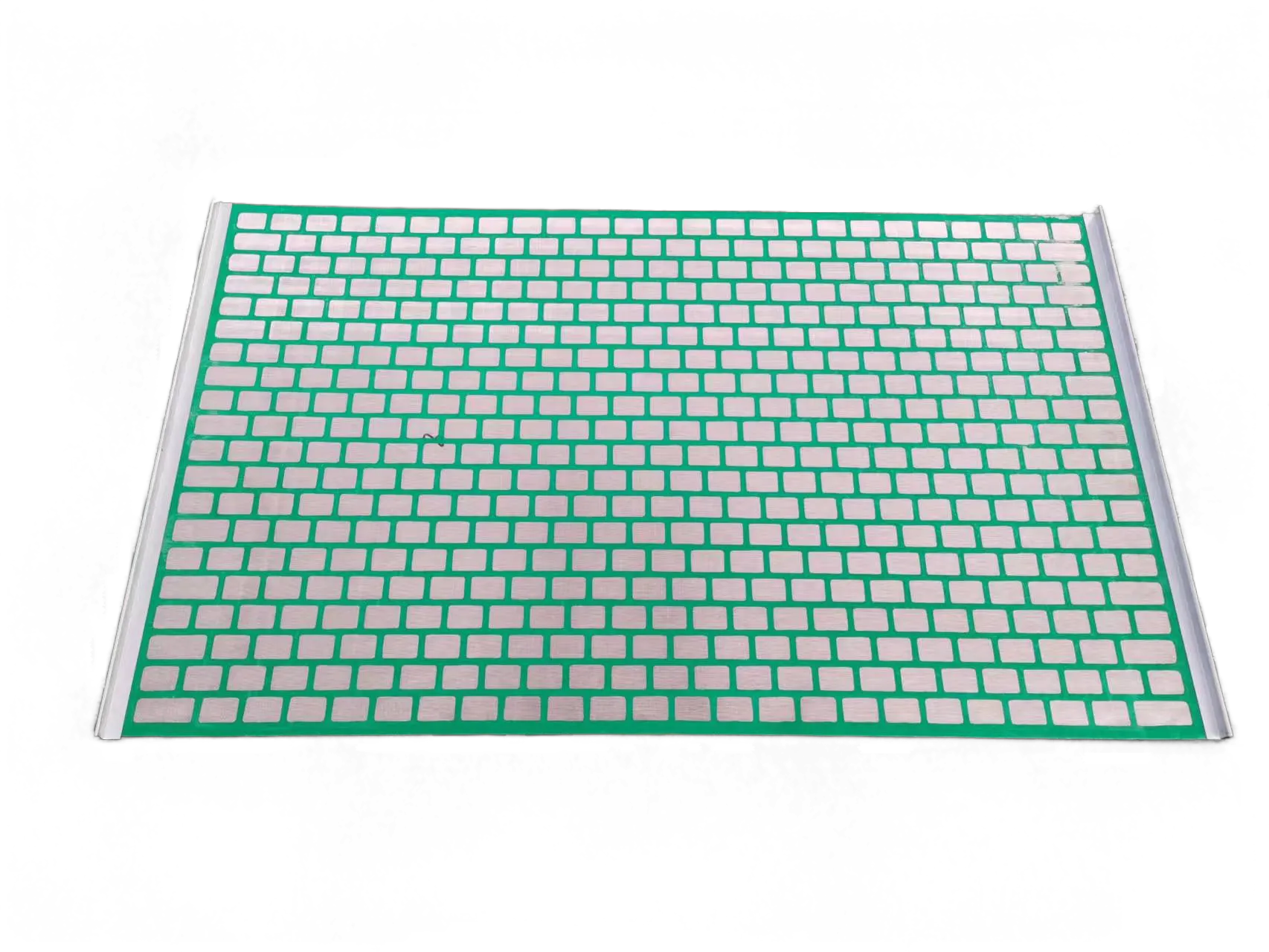

galvanized grating price

Navigating the landscape of galvanized grating pricing requires not just an understanding of the product itself, but also an insight into the factors that influence costs. In an industry where precise specifications can drastically alter pricing, potential buyers must be informed to make cost-effective decisions. With my extensive experience in SEO and product-specific insights, I aim to provide a comprehensive overview that extends beyond simple cost discussions, offering expertise and building trustworthiness among readers.

Moreover, the zinc coating thickness also contributes to pricing fluctuations. A thicker zinc layer offers enhanced protection and may increase initial costs but potentially lower long-term maintenance expenses. Consequently, projects with a longer horizon often justify this investment upfront to avoid future repair or replacement costs. Supply chain factors, such as the origin of materials and transportation logistics, undoubtedly impact pricing as well. Gratings manufactured locally may offer lower transportation costs, but global supply chain challenges can lead to unexpected price variations. As the world continues to see shifts in global trade dynamics, being aware of these factors can help purchasers mitigate unforeseen cost increases. Engaging with knowledgeable suppliers can be instrumental in making an informed purchase decision. Experienced suppliers not only provide competitive pricing but also offer insights into market trends and future cost predictions. Developing a relationship with a reputable supplier ensures access to high-quality products, transparent pricing structures, and potential project-specific discounts or advisories. Finally, bulk purchases generally offer an opportunity for cost savings. For large-scale installations, buying in volume may present a significant reduction per unit price, making it a strategic consideration for extensive projects. Engaging in negotiations focused on volume discounting can yield favorable purchasing agreements. In conclusion, understanding galvanized grating pricing demands a multifaceted approach comprising material choice, manufacturing processes, cost-effective procurement strategies, and keen market insights. While initial costs are crucial, it's equally important to consider long-term value implications such as maintenance and replacement timelines. With this comprehensive understanding, buyers can confidently navigate pricing structures and effectively plan their acquisitions, ensuring optimal resource allocation and successful project outcomes. Whether you're an industry veteran or a newcomer seeking information, being armed with this knowledge ensures proactive, informed decision-making in the ever-evolving world of galvanized grating.

Moreover, the zinc coating thickness also contributes to pricing fluctuations. A thicker zinc layer offers enhanced protection and may increase initial costs but potentially lower long-term maintenance expenses. Consequently, projects with a longer horizon often justify this investment upfront to avoid future repair or replacement costs. Supply chain factors, such as the origin of materials and transportation logistics, undoubtedly impact pricing as well. Gratings manufactured locally may offer lower transportation costs, but global supply chain challenges can lead to unexpected price variations. As the world continues to see shifts in global trade dynamics, being aware of these factors can help purchasers mitigate unforeseen cost increases. Engaging with knowledgeable suppliers can be instrumental in making an informed purchase decision. Experienced suppliers not only provide competitive pricing but also offer insights into market trends and future cost predictions. Developing a relationship with a reputable supplier ensures access to high-quality products, transparent pricing structures, and potential project-specific discounts or advisories. Finally, bulk purchases generally offer an opportunity for cost savings. For large-scale installations, buying in volume may present a significant reduction per unit price, making it a strategic consideration for extensive projects. Engaging in negotiations focused on volume discounting can yield favorable purchasing agreements. In conclusion, understanding galvanized grating pricing demands a multifaceted approach comprising material choice, manufacturing processes, cost-effective procurement strategies, and keen market insights. While initial costs are crucial, it's equally important to consider long-term value implications such as maintenance and replacement timelines. With this comprehensive understanding, buyers can confidently navigate pricing structures and effectively plan their acquisitions, ensuring optimal resource allocation and successful project outcomes. Whether you're an industry veteran or a newcomer seeking information, being armed with this knowledge ensures proactive, informed decision-making in the ever-evolving world of galvanized grating.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024