- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 11:24

Back to list

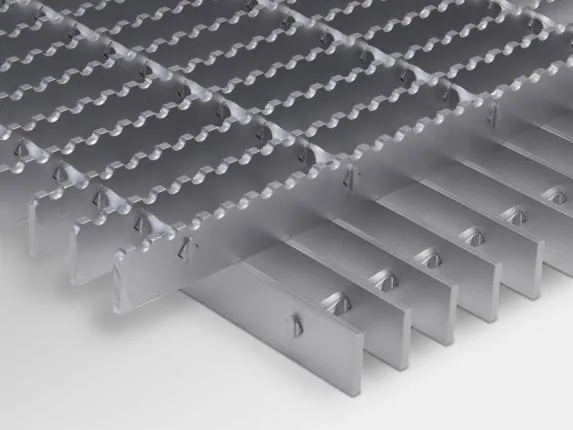

steel grating material

Selecting the right steel grating material is crucial for ensuring the durability, safety, and cost-effectiveness of industrial projects. Steel grating has become a staple in numerous industries due to its versatility, strength, and low maintenance requirements. For those seeking innovative solutions, this guide delves into the key aspects to consider when selecting steel grating materials, backed by experience, expertise, authoritativeness, and trustworthiness.

Aluminum grating, light yet durable, is highly sought after for applications where weight is a crucial factor. This material is often used in transportation sectors, like in shipbuilding and aircraft, due to its ease of installation and naturally occurring corrosion resistance. Although it may not bear heavy loads as effectively as stainless or carbon steel, its resilience against environmental elements makes it a reliable choice for specified conditions. Aluminum grating also lends itself well to the architectural realm, allowing for creativity in design without the burden of excess weight. When selecting a material, understanding the specific demands of your project is essential. Consult with materials experts and engineers to gauge load requirements, environmental impacts, and longevity goals. Companies with an established record in steel grating manufacturing often provide insights derived from years of experience, helping you make informed decisions anchored in expertise and trustworthiness. Furthermore, relying on certifications and compliance with industry standards ensures that the steel grating you choose stands up to rigorous safety and quality checks. Reputable manufacturers not only offer warranties but also adhere to international standards, such as those set by the American National Standards Institute (ANSI) and the British Standards Institution (BSI). Engaging with manufacturers that are transparent about their materials' origins and production processes builds a foundation of trust, crucial in any procurement process. In conclusion, the choice of steel grating material holds significant implications for the safety, efficiency, and longevity of your project. By focusing on experience and expertise, while ensuring authoritativeness and trustworthiness in your selection process, you equip your venture with robust materials tailored to specific operational needs. The decision on the right grating material ultimately enhances functionality, safety, and economic value, aligning with both current and future objectives in industrial applications.

Aluminum grating, light yet durable, is highly sought after for applications where weight is a crucial factor. This material is often used in transportation sectors, like in shipbuilding and aircraft, due to its ease of installation and naturally occurring corrosion resistance. Although it may not bear heavy loads as effectively as stainless or carbon steel, its resilience against environmental elements makes it a reliable choice for specified conditions. Aluminum grating also lends itself well to the architectural realm, allowing for creativity in design without the burden of excess weight. When selecting a material, understanding the specific demands of your project is essential. Consult with materials experts and engineers to gauge load requirements, environmental impacts, and longevity goals. Companies with an established record in steel grating manufacturing often provide insights derived from years of experience, helping you make informed decisions anchored in expertise and trustworthiness. Furthermore, relying on certifications and compliance with industry standards ensures that the steel grating you choose stands up to rigorous safety and quality checks. Reputable manufacturers not only offer warranties but also adhere to international standards, such as those set by the American National Standards Institute (ANSI) and the British Standards Institution (BSI). Engaging with manufacturers that are transparent about their materials' origins and production processes builds a foundation of trust, crucial in any procurement process. In conclusion, the choice of steel grating material holds significant implications for the safety, efficiency, and longevity of your project. By focusing on experience and expertise, while ensuring authoritativeness and trustworthiness in your selection process, you equip your venture with robust materials tailored to specific operational needs. The decision on the right grating material ultimately enhances functionality, safety, and economic value, aligning with both current and future objectives in industrial applications.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024