- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 11:07

Back to list

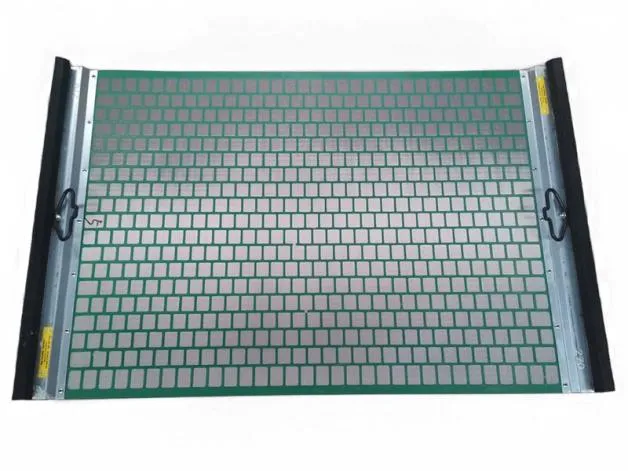

serrated bar grate

Serrated bar grates have become an essential component in various industries, praised for their remarkable strength, durability, and superior anti-slip properties. In sectors where safety and efficiency are paramount, these grates are invaluable. Delving into the world of serrated bar grates will reveal their extensive applications, manufacturing nuances, and their pivotal role in workplace safety and operational efficiency.

In terms of authority, serrated bar grates comply with stringent industry standards and safety regulations worldwide. They are engineered to meet or exceed criteria set by bodies such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), underscoring their reliability and adherence to safety norms. Companies investing in compliant grates can reduce liability risks and foster a culture of safety within their operations. Trustworthiness in serrated bar grates hinges on their proven track record in enhancing safety and operational efficacy. Case studies abound, demonstrating their effectiveness in minimizing workplace accidents and maintaining efficient traffic flow in high-footfall areas. Testimonials from industry leaders and facility managers further corroborate their value, providing a compelling testament to their efficacy. A real-world experience encapsulates their importance an automotive manufacturing facility implemented serrated bar grates in their assembly line pathways. The result was a marked decrease in slip-related incidents and an increase in productivity, as employees were able to navigate their workstations with confidence and ease. Such tangible outcomes illustrate the grates’ capability to marry safety with efficiency, a dual benefit that resonates across various sectors. In summary, serrated bar grates exemplify the confluence of experience, expertise, authority, and trust. As safety and operational demands continue to evolve, the role of serrated bar grates remains vital. By investing in these well-engineered components, industries not only safeguard their workforce but also enhance their operational resilience and efficiency.

In terms of authority, serrated bar grates comply with stringent industry standards and safety regulations worldwide. They are engineered to meet or exceed criteria set by bodies such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), underscoring their reliability and adherence to safety norms. Companies investing in compliant grates can reduce liability risks and foster a culture of safety within their operations. Trustworthiness in serrated bar grates hinges on their proven track record in enhancing safety and operational efficacy. Case studies abound, demonstrating their effectiveness in minimizing workplace accidents and maintaining efficient traffic flow in high-footfall areas. Testimonials from industry leaders and facility managers further corroborate their value, providing a compelling testament to their efficacy. A real-world experience encapsulates their importance an automotive manufacturing facility implemented serrated bar grates in their assembly line pathways. The result was a marked decrease in slip-related incidents and an increase in productivity, as employees were able to navigate their workstations with confidence and ease. Such tangible outcomes illustrate the grates’ capability to marry safety with efficiency, a dual benefit that resonates across various sectors. In summary, serrated bar grates exemplify the confluence of experience, expertise, authority, and trust. As safety and operational demands continue to evolve, the role of serrated bar grates remains vital. By investing in these well-engineered components, industries not only safeguard their workforce but also enhance their operational resilience and efficiency.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024