- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 03, 2025 12:56

Back to list

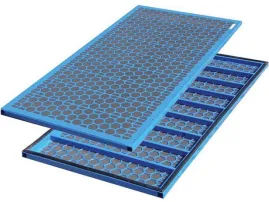

steel grating for sale

Steel grating has emerged as an essential component across various industries, renowned for its durability, strength, and versatility. Defined by its open-grid assembly, steel grating allows for the passage of light, air, and liquids, making it the preferred choice for numerous commercial and industrial applications.

Customers should consult manufacturers who adhere to rigorous quality standards. Such manufacturers often demonstrate their authoritativeness and reliability by adhering to industry certifications, like ISO standards. Certifications not only affirm a commitment to quality but also bolster the trust, a critical component when large-scale orders are involved. Speaking with seasoned professionals also tends to yield beneficial insights about the availability of custom solutions. Whether it involves specific coatings, different materials, or unique dimensions, reputable manufacturers can typically customize grating products to meet specific criteria. Such bespoke services underscore the flexibility and comprehensive nature of the service offered, fostering client trust and satisfaction. Furthermore, sustainability has taken center stage in many industries, and steel grating is no exception. Learn about environmentally-friendly practices being adopted by manufacturers, such as using recycled materials or implementing energy-efficient processes. An authoritative supplier should be able to articulate their approach to sustainability clearly, further solidifying trust. Finally, before committing to a purchase, it is prudent to solicit testimonials or case studies demonstrating the product's performance in real-world scenarios. Engaging with reviews or directly connecting with current or past clients can provide perspectives on the usability and longevity of the grating in situations similar to those you are considering. Ultimately, investing in the right steel grating is about understanding your unique industry requirements and seeking products that align with these standards. With informed decision-making, expert consultations, and a commitment to prioritize both quality and trust, the likelihood of purchasing the ideal steel grating solution dramatically increases. By embracing these insights, informed by your specific industry context, your steel grating decision can integrate experience, expertise, authoritativeness, and trustworthiness seamlessly into your industrial needs.

Customers should consult manufacturers who adhere to rigorous quality standards. Such manufacturers often demonstrate their authoritativeness and reliability by adhering to industry certifications, like ISO standards. Certifications not only affirm a commitment to quality but also bolster the trust, a critical component when large-scale orders are involved. Speaking with seasoned professionals also tends to yield beneficial insights about the availability of custom solutions. Whether it involves specific coatings, different materials, or unique dimensions, reputable manufacturers can typically customize grating products to meet specific criteria. Such bespoke services underscore the flexibility and comprehensive nature of the service offered, fostering client trust and satisfaction. Furthermore, sustainability has taken center stage in many industries, and steel grating is no exception. Learn about environmentally-friendly practices being adopted by manufacturers, such as using recycled materials or implementing energy-efficient processes. An authoritative supplier should be able to articulate their approach to sustainability clearly, further solidifying trust. Finally, before committing to a purchase, it is prudent to solicit testimonials or case studies demonstrating the product's performance in real-world scenarios. Engaging with reviews or directly connecting with current or past clients can provide perspectives on the usability and longevity of the grating in situations similar to those you are considering. Ultimately, investing in the right steel grating is about understanding your unique industry requirements and seeking products that align with these standards. With informed decision-making, expert consultations, and a commitment to prioritize both quality and trust, the likelihood of purchasing the ideal steel grating solution dramatically increases. By embracing these insights, informed by your specific industry context, your steel grating decision can integrate experience, expertise, authoritativeness, and trustworthiness seamlessly into your industrial needs.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024