- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 03, 2025 12:36

Back to list

helideck perimeter safety nets

Helideck perimeter safety nets are crucial components in ensuring the safety and functionality of offshore and onshore helidecks. These nets serve a fundamental role, often overlooked, in preventing serious accidents during helicopter operations. With an intricate mix of experience, expertise, authority, and trustworthiness, understanding the ins and outs of these nets is essential for industry professionals aiming to uphold the highest safety standards.

Trustworthiness in the realm of helideck safety nets revolves around continuous advancements in technology and materials. Companies leading this sector invest in research and development to pioneer innovations that increase net durability and ease of installation. Trust is further bolstered by transparency in testing methods and results, enabling purchasers to make informed decisions based on reliable data. Moreover, the role of helideck perimeter safety nets is expanding with advances in helicopter technology and the increasing complexity of offshore operations. As helicopters become more advanced, the safety measures supporting them must evolve in tandem. This requires a continual reassessment of net design, materials used, and installation techniques to ensure that they not only support current needs but anticipate future requirements. The human factor must also be accounted for in any discussion about safety measures. Rigorous training for all personnel involved with helideck operations is non-negotiable. Regular drills and safety seminars ensure that every crew member is familiar with the use and maintenance of safety equipment, including perimeter nets, thereby minimizing the risk of human error. Client testimonials and case studies provide practical insights into the real-world application of helideck perimeter safety nets. Feedback often highlights the peace of mind that comes with high-quality installations—knowing that they have a reliable barrier that offers critical protection during the chaotic environment of a helicopter takeoff or landing. This practical feedback loop allows manufacturers to continuously improve and adapt their offerings, creating products that are as resilient as they are reliable. In conclusion, helideck perimeter safety nets are a foundational aspect of any helideck safety system. Combining cutting-edge engineering with rigorous compliance standards helps create a product that stands as a testament to the industry’s commitment to safety and innovation. The synthesis of experience, expertise, authority, and trustworthiness ensures that these nets will continue to play a vital role in keeping helidecks safe for years to come.

Trustworthiness in the realm of helideck safety nets revolves around continuous advancements in technology and materials. Companies leading this sector invest in research and development to pioneer innovations that increase net durability and ease of installation. Trust is further bolstered by transparency in testing methods and results, enabling purchasers to make informed decisions based on reliable data. Moreover, the role of helideck perimeter safety nets is expanding with advances in helicopter technology and the increasing complexity of offshore operations. As helicopters become more advanced, the safety measures supporting them must evolve in tandem. This requires a continual reassessment of net design, materials used, and installation techniques to ensure that they not only support current needs but anticipate future requirements. The human factor must also be accounted for in any discussion about safety measures. Rigorous training for all personnel involved with helideck operations is non-negotiable. Regular drills and safety seminars ensure that every crew member is familiar with the use and maintenance of safety equipment, including perimeter nets, thereby minimizing the risk of human error. Client testimonials and case studies provide practical insights into the real-world application of helideck perimeter safety nets. Feedback often highlights the peace of mind that comes with high-quality installations—knowing that they have a reliable barrier that offers critical protection during the chaotic environment of a helicopter takeoff or landing. This practical feedback loop allows manufacturers to continuously improve and adapt their offerings, creating products that are as resilient as they are reliable. In conclusion, helideck perimeter safety nets are a foundational aspect of any helideck safety system. Combining cutting-edge engineering with rigorous compliance standards helps create a product that stands as a testament to the industry’s commitment to safety and innovation. The synthesis of experience, expertise, authority, and trustworthiness ensures that these nets will continue to play a vital role in keeping helidecks safe for years to come.

Share

Prev:

Next:

Latest news

-

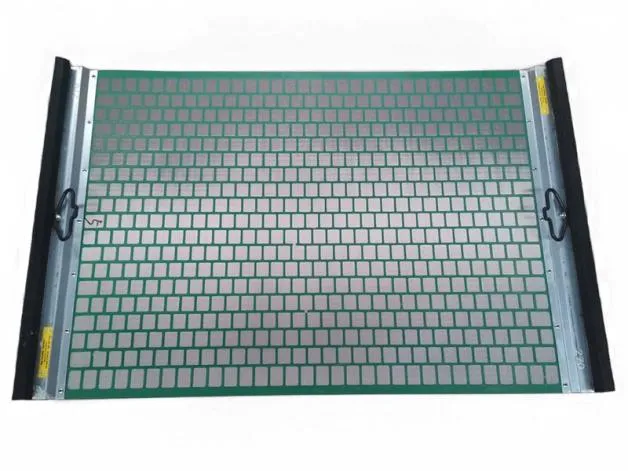

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

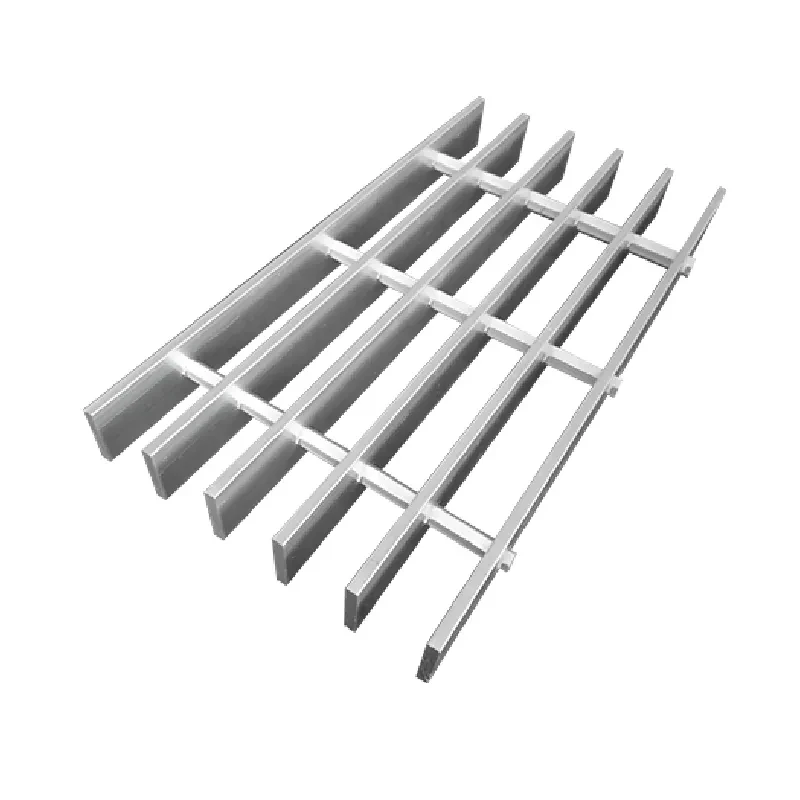

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024