- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 23, 2025 03:50

Back to list

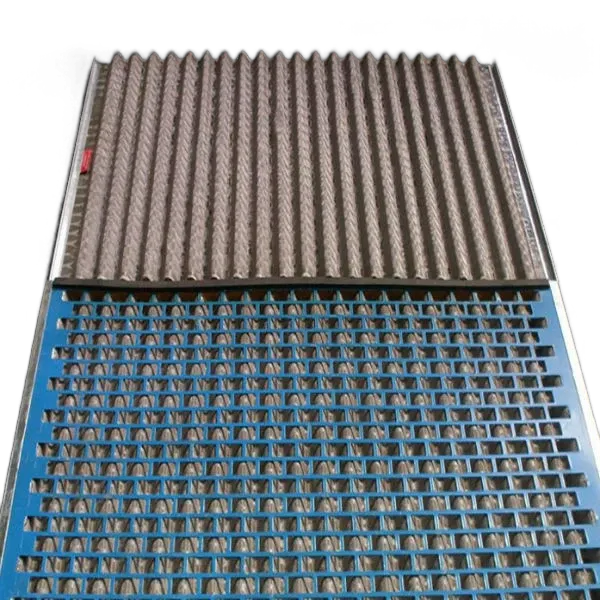

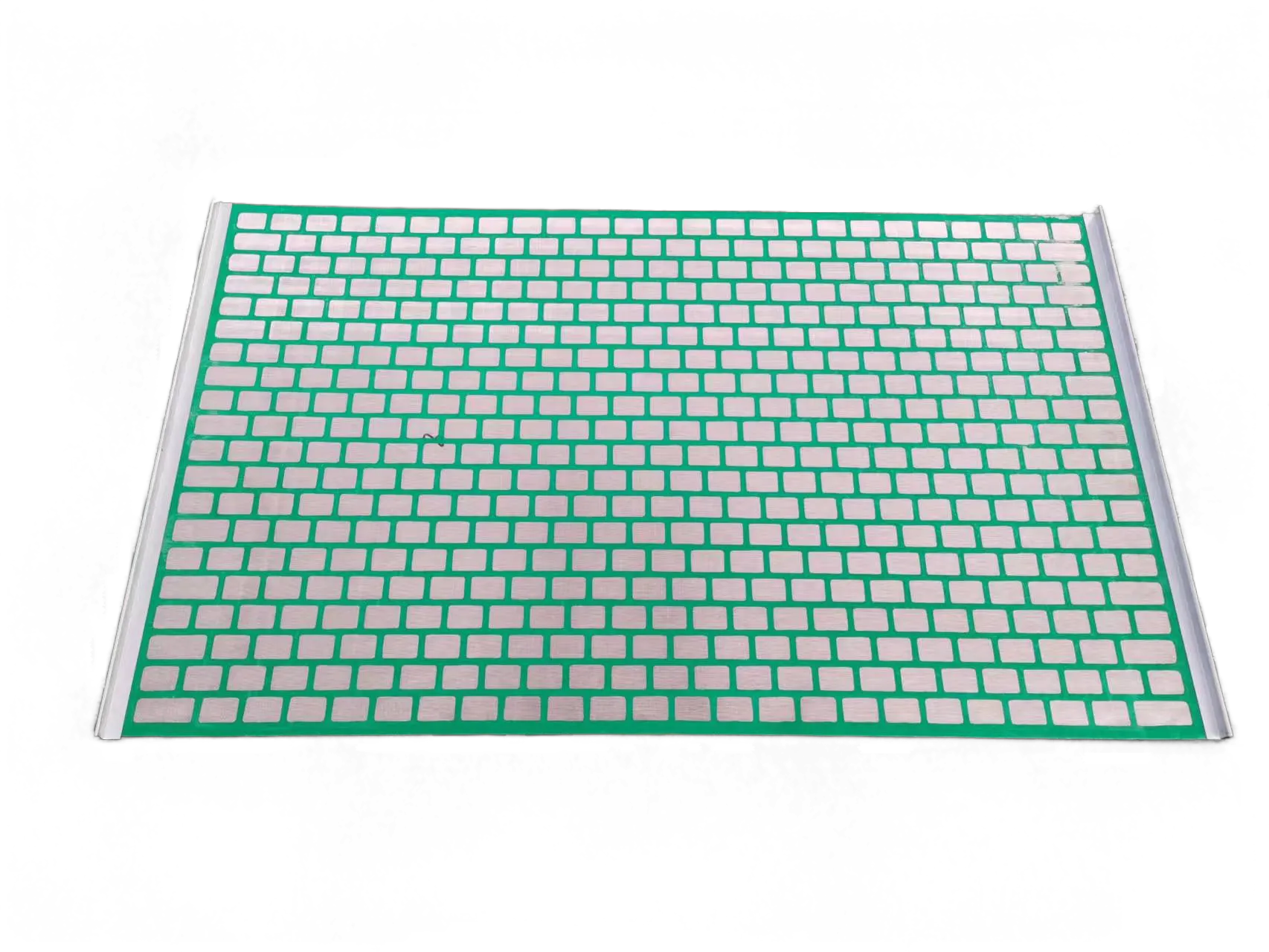

steel walkway grating

When considering construction materials for projects, steel grating often emerges as a preferred choice due to its combination of strength, durability, and versatility. However, for a detailed project budget, understanding the cost per square foot is essential. Drawing from extensive experience in the construction industry, this article delves into the factors influencing the pricing of steel grating, providing clarity and insight for those contemplating its use.

Installation considerations should also not be overlooked when calculating overall costs. Steel grating requires precise installation to ensure safety and functionality, often necessitating specialized labor. The complexity of the installation can influence both time and cost, particularly if custom fittings or precise adjustments are needed. In addition to material and installation costs, the total cost of ownership should be factored into the decision-making process. Steel grating's durability means a potential for significantly reduced maintenance costs over time compared to other materials. In high-traffic or industrial settings, this durability also translates to fewer replacements and repairs, resulting in long-term financial savings. Choosing the right supplier is another aspect closely related to cost-effectiveness. Reputable suppliers with expertise in steel products often provide better quality assurance and service, in addition to more competitive pricing options due to their established position in the market. It's advisable to seek a supplier with a strong track record in the industry, as well as one who offers post-purchase support and services. Understanding these dynamics ensures better budget planning and can lead to a significant impact on cost efficiency. From initial purchase to long-term maintenance, selecting steel grating tailored to the specific needs of your project can yield substantial benefits in terms of both function and finances. In summary, the cost per square foot of steel grating is a nuanced figure, contingent on various factors such as material specifications, finishing processes, and overall installation logistics. By engaging in careful planning and considering the full spectrum of elements that influence cost, stakeholders can optimize their project outcomes while ensuring their investment in steel grating aligns with their fiscal and operational objectives.

Installation considerations should also not be overlooked when calculating overall costs. Steel grating requires precise installation to ensure safety and functionality, often necessitating specialized labor. The complexity of the installation can influence both time and cost, particularly if custom fittings or precise adjustments are needed. In addition to material and installation costs, the total cost of ownership should be factored into the decision-making process. Steel grating's durability means a potential for significantly reduced maintenance costs over time compared to other materials. In high-traffic or industrial settings, this durability also translates to fewer replacements and repairs, resulting in long-term financial savings. Choosing the right supplier is another aspect closely related to cost-effectiveness. Reputable suppliers with expertise in steel products often provide better quality assurance and service, in addition to more competitive pricing options due to their established position in the market. It's advisable to seek a supplier with a strong track record in the industry, as well as one who offers post-purchase support and services. Understanding these dynamics ensures better budget planning and can lead to a significant impact on cost efficiency. From initial purchase to long-term maintenance, selecting steel grating tailored to the specific needs of your project can yield substantial benefits in terms of both function and finances. In summary, the cost per square foot of steel grating is a nuanced figure, contingent on various factors such as material specifications, finishing processes, and overall installation logistics. By engaging in careful planning and considering the full spectrum of elements that influence cost, stakeholders can optimize their project outcomes while ensuring their investment in steel grating aligns with their fiscal and operational objectives.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024