- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

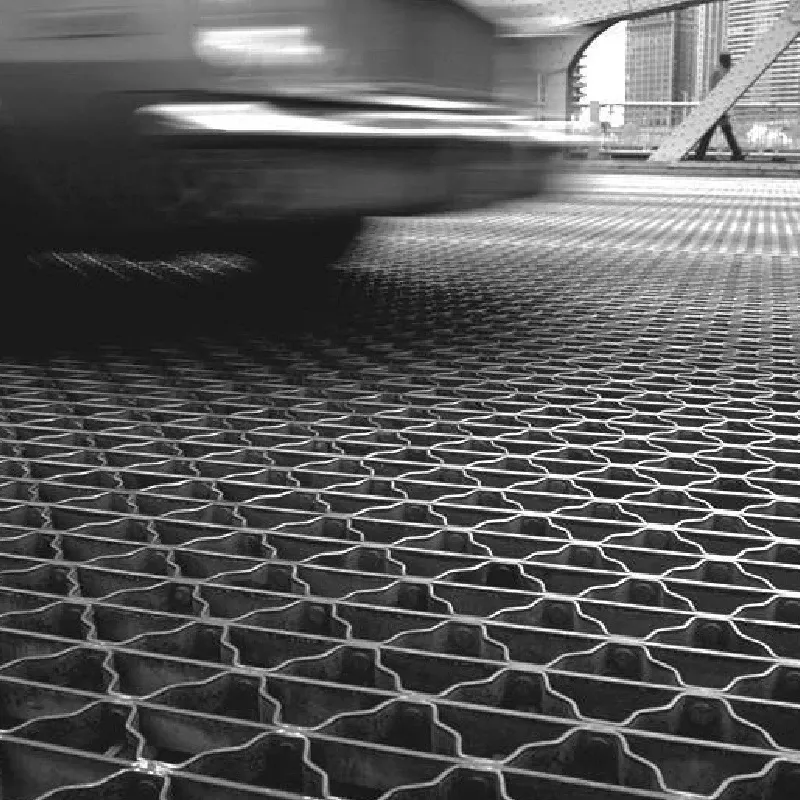

Durable Steel Bar Grating for Enhanced Structural Support and Versatile Applications

Understanding Steel Bar Grating A Versatile Solution for a Variety of Applications

Steel bar grating is a widely used structural element made from steel bars that are welded or press-locked together, creating a grid-like pattern. It serves as a vital component in various industries, including construction, manufacturing, and transportation. The unique properties and versatility of steel bar grating make it an ideal choice for many applications.

Composition and Manufacturing Process

Steel bar grating is primarily composed of carbon steel, stainless steel, or aluminum. Carbon steel is the most common material due to its strength and cost-effectiveness. The manufacturing process typically involves the cutting of flat steel bars into designated lengths followed by a welding or pressure-locking technique to form a grid structure. The resulting panels can be fabricated in various sizes and can be customized to meet specific requirements.

Types of Steel Bar Grating

Steel bar grating is available in different types depending on the arrangement of the bars. The most common styles include

1. Straight Bar Grating This type features parallel bars that run in one direction, providing a flat surface suitable for walkways, platforms, and ramps. 2. Checker Plate Grating Combining functionality with aesthetic appeal, checker plate grating has a raised pattern that enhances traction. This makes it ideal for areas where slip resistance is a priority.

3. Heavy-Duty Grating Designed to withstand heavy loads, this type of grating is often used in industrial settings, such as factory floors and loading docks.

4. Open-Grated Grating Featuring larger openings between the bars, this style allows for excellent drainage and airflow, making it suitable for outdoor areas exposed to rain or snow.

Advantages of Steel Bar Grating

Steel bar grating offers numerous advantages that make it a preferred material in various applications

1. Durability Steel is known for its exceptional strength and longevity. Properly maintained steel bar grating can last for decades, making it a cost-effective solution in the long run.

steel bar grating

2. Low Maintenance Unlike other materials, steel bar grating requires minimal maintenance. Regular cleaning and occasional inspections can ensure its integrity without the need for frequent repairs.

3. Versatile Applications Steel bar grating is used in multiple settings, including industrial plants, commercial buildings, bridges, and walkways. It can also be tailored to fit specific needs, such as custom sizes and load specifications.

4. Safety Many types of steel grating offer slip-resistant surfaces, critical for areas prone to spills or slippery conditions. The open design promotes drainage, reducing the risk of water accumulation.

5. Cost-Effectiveness While the initial cost of steel bar grating may be higher than less durable materials, its longevity and low maintenance needs can lead to lower total ownership costs.

Applications in Various Industries

Steel bar grating is used across multiple sectors for various applications

- Construction It’s commonly used in walkways, stair treads, and platforms, providing safe and stable surfaces for foot traffic.

- Manufacturing In factories, steel bar grating serves as flooring for workstations, machine platforms, and catwalks, allowing for easy access to machinery and equipment.

- Transportation Steel grating is often used in bridges and walkways that require strength and safety, as well as in railway applications where visibility and drainage are essential.

- Wastewater Treatment The grating’s open design makes it a popular choice for grates and covers in wastewater treatment plants, facilitating effective drainage and filtration.

Conclusion

Steel bar grating is a reliable and versatile solution for numerous applications across various industries. Its strength, durability, and low maintenance needs make it an attractive choice for architects, engineers, and business owners. As industries continue to evolve, steel bar grating will remain an essential component in creating safe and efficient environments. Whether in a commercial building, manufacturing facility, or outdoor setting, the benefits of steel bar grating are clear, establishing it as a fundamental material in modern construction and infrastructure.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024