- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

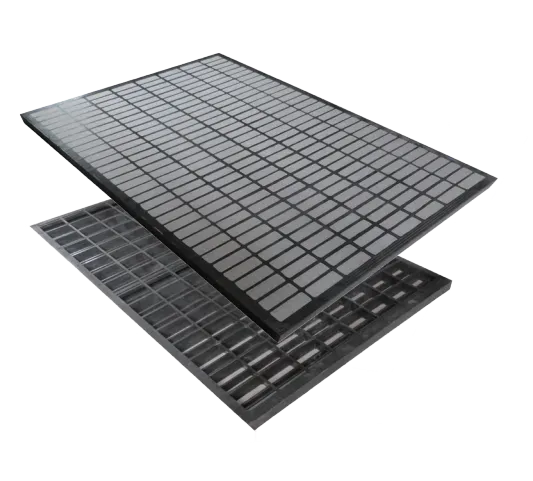

bar grating cost

Understanding the Cost of Bar Grating Factors and Insights

Bar grating is a widely used material in various industries, serving applications ranging from flooring to drainage covers. Its versatility, strength, and durability make it a popular choice for industrial facilities, commercial buildings, and even residential projects. However, understanding the cost associated with bar grating is essential for contractors, architects, and project managers. This article delves into the factors influencing the cost of bar grating and offers insights to help stakeholders make informed decisions.

Types of Bar Grating

The cost of bar grating can vary significantly depending on the type. The two primary types of bar grating are welded and press-locked. Welded bar grating is made by welding crossbars into a frame of bearing bars, resulting in a robust structure. Press-locked grating, on the other hand, uses a series of pressure to hold the crossbars in place without welding, which can sometimes make it less expensive. Additionally, there are specialized grating options such as molded grating, which is often used for corrosive environments, and extruded grating, known for its lightweight and corrosion resistance. Each type carries its own cost implications based on manufacturing processes and material specifications.

Material Choices

The materials used in bar grating also play a significant role in determining costs. Common materials include carbon steel, stainless steel, aluminum, and fiberglass. Carbon steel grating is generally the most affordable option but may require protective coatings to prevent rust, which adds to the lifecycle cost. Stainless steel, while more expensive upfront, offers superior resistance to corrosion and can be more economical in the long run due to lower maintenance costs. Aluminum grating is lightweight and resistant to rust, making it suitable for various applications, though it often comes at a higher initial cost. Fiberglass grating may be the most expensive option but provides excellent corrosion resistance and is a preferred choice in highly corrosive environments.

bar grating cost

Size and Configuration

The dimensions and configuration of bar grating can also affect pricing. Standard sizes are typically less expensive than custom sizes, so understanding project specifications beforehand can lead to cost savings. The spacing between bearing bars, known as the load bar spacing, is another critical factor. Wider spacing can reduce material costs but might not always meet the necessary load capacity requirements for specific applications.

Installation and Maintenance Costs

Beyond the initial purchase price, installation and maintenance costs must be considered when calculating the total cost of bar grating. While some types of bar grating can be installed quickly and easily, others may require specialized labor, adding to the overall expense. Furthermore, certain materials may demand more maintenance, influencing long-term budgeting strategies.

Conclusion

Understanding the various factors that impact the cost of bar grating is crucial for effective project budgeting and outcome management. By considering the type of grating, material choices, size and configuration, as well as installation and maintenance aspects, stakeholders can make informed decisions that align with both project requirements and budget constraints. As industries continue to evolve, staying informed about these cost dynamics will help ensure the successful application of bar grating in diverse settings.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024