- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Standard Sizes for Steel Grating and Their Applications in Various Industries

Understanding Steel Grating Standard Sizes An Essential Guide

Steel grating is an industrial material widely used in various sectors due to its strength, durability, and versatility. From walkways to drainage covers, steel grating plays a vital role in ensuring safety and efficiency in industrial and commercial applications. One critical aspect of utilizing steel grating effectively is understanding its standard sizes.

What is Steel Grating?

Steel grating is a type of material made from steel bars that are welded together in a pattern to create a grid-like structure. This design allows for maximum airflow and drainage while providing robust support for foot traffic or heavy machinery. Steel grating comes in various types, including welded, swage-locked, and press-locked, each offering unique strength and resistance properties suitable for different uses.

Importance of Standard Sizes

Standard sizes for steel grating are crucial for several reasons. Firstly, they ensure compatibility with existing structures and systems. When maintenance or replacement is necessary, having standardized dimensions simplifies the process and minimizes mismatches. Secondly, standard sizes facilitate bulk purchasing, which can significantly reduce costs for businesses. This consistency also aids in inventory management, making it easier for suppliers and manufacturers to maintain stock levels.

Common Standard Sizes

While steel grating can be custom-made to fit specific requirements, most applications utilize standard sizes. Here are some of the most commonly used dimensions

steel grating standard sizes

1. Thickness The thickness of steel grating typically ranges from 1/4 inch to 1 inch. Thicker grates provide more strength and durability, making them suitable for heavy-duty applications, while thinner options might be adequate for pedestrian areas.

2. Panel Sizes Standard panel sizes generally measure 24 inches by 48 inches, though other sizes like 30 inches by 30 inches or 36 inches by 72 inches are also available. The choice of panel size often depends on the application, with larger panels being preferable for expansive spaces to minimize the number of joints or seams.

3. Bearing Bar Spacing The spacing between the bearing bars is an essential factor that affects load-bearing capacity and drainage. Standard spacing usually ranges from 1 inch to 4 inches, depending on the load requirements and intended use.

4. Opening Size The size of openings in the grating can vary, but standard options often feature openings of approximately 1 inch by 4 inches or 2 inches by 4 inches. This size strikes a balance between providing adequate drainage and preventing objects from falling through.

Applications of Standard-Sized Steel Grating

The applications of standard-sized steel grating are vast. In industrial settings, it is commonly used for platforms, walkways, and stair treads, engineered to withstand significant weight loads while allowing easy access to machinery and equipment. In commercial settings, steel grating is often employed for drainage systems in parking lots and walkways, ensuring efficient water runoff during heavy rains.

Conclusion

In summary, understanding the standard sizes of steel grating is essential for ensuring safety, compatibility, and cost-effectiveness in various applications. By utilizing standard dimensions, businesses can streamline their operations and enhance the reliability of their industrial and commercial spaces. As steel grating continues to be a favored material in construction and infrastructure projects, knowledge of its standard sizes will remain a significant asset for designers, engineers, and contractors alike.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

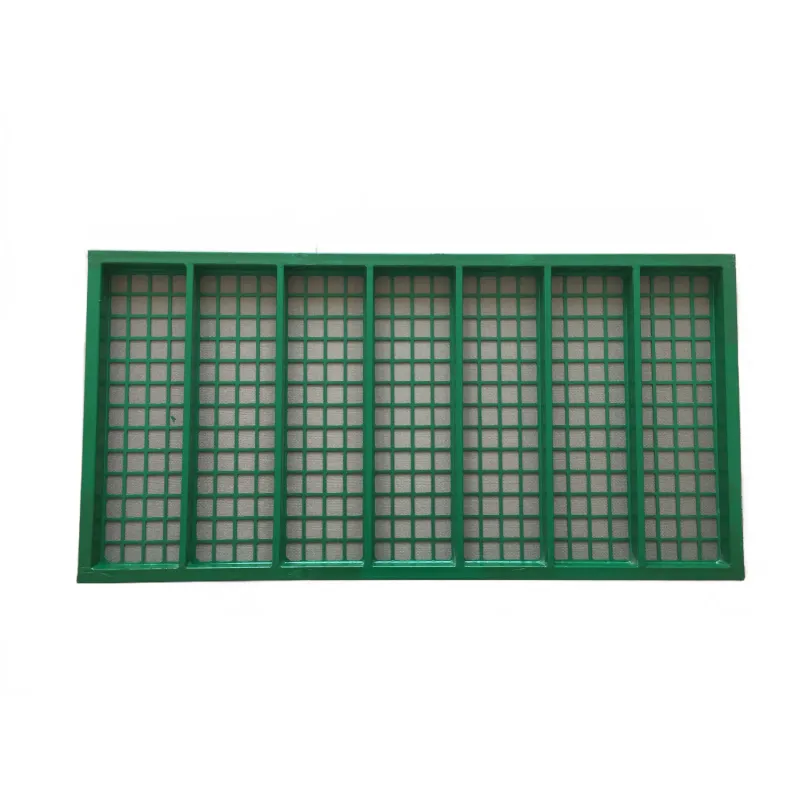

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024