- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Aluminum Grate Sheets for Durable and Lightweight Construction Solutions

Understanding Aluminum Grate Sheets Features, Benefits, and Applications

Aluminum grate sheets have become increasingly popular in various industries due to their remarkable properties and versatility. Made from aluminum, a lightweight yet robust metal, these sheets offer an array of advantages that make them suitable for countless applications. In this article, we will explore the features, benefits, and common uses of aluminum grate sheets.

Features of Aluminum Grate Sheets

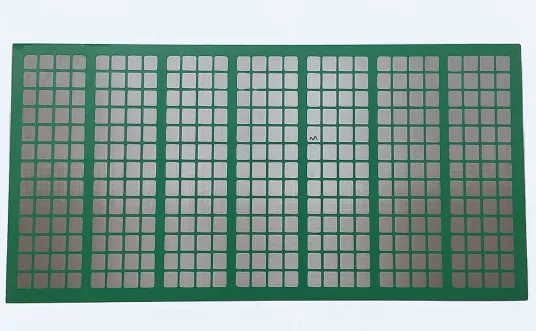

Aluminum grate sheets are characterized by their grid-like structure, which provides strength while allowing for optimal airflow and drainage. The sheets are manufactured through a process of fabrication that includes cutting, welding, and finishing to ensure durability and resilience. One of the key features of aluminum grate sheets is their anti-corrosive nature, making them ideal for environments exposed to moisture and chemicals. Additionally, the lightweight quality of aluminum makes these sheets easy to handle and install.

The design of aluminum grate sheets can also vary, with options for different hole sizes and patterns. Some sheets may feature non-slip surfaces, which enhance safety in high-traffic areas. Furthermore, aluminum can be anodized or powder-coated, providing additional protection against wear and tear while also allowing for customization in color and finish.

Benefits of Aluminum Grate Sheets

One of the most significant benefits of aluminum grate sheets is their strength-to-weight ratio. Compared to other materials like steel, aluminum offers similar levels of durability while being considerably lighter. This feature not only facilitates easier installation but also reduces strain on supporting structures.

aluminum grate sheet

Another notable benefit is the material’s resistance to corrosion. Unlike steel, which can rust when exposed to moisture, aluminum oxide forms a protective layer that shields it from environmental damage. This makes aluminum grate sheets particularly well-suited for outdoor applications and environments prone to chemical exposure, such as factories or wastewater treatment plants.

In terms of maintenance, aluminum grate sheets require minimal upkeep. Their smooth surfaces can be easily cleaned, and they are less likely to harbor contaminants due to their non-porous nature. This low-maintenance aspect is especially advantageous in industries where hygiene is crucial, such as food processing and pharmaceuticals.

Common Applications

Aluminum grate sheets are utilized in a wide array of applications across different sectors. In construction and architecture, they are often used for walkways, platform flooring, and stair treads, providing both safety and aesthetic appeal. In industrial settings, these sheets serve as effective flooring solutions in warehouses and factories, facilitating efficient drainage while ensuring stability.

Another common application is in the transportation sector, where aluminum grate sheets are used in railway platforms and as part of vehicle ramps. Their lightweight properties and resistance to wear make them an excellent choice for enhancing safety and accessibility. Additionally, in the agricultural sector, aluminum grates are popular for use in livestock facilities, providing a durable and easy-to-clean surface for animal husbandry.

In summary, aluminum grate sheets are a versatile solution that combines strength, durability, and low maintenance in one package. Their lightweight nature and resistance to corrosion make them an ideal choice for a wide range of industries, ensuring safety and efficiency in various applications. As industries continue to seek innovative materials that provide long-lasting performance while reducing overall weight, aluminum grate sheets will undoubtedly remain a preferred option for many.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024