- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 01:36

Back to list

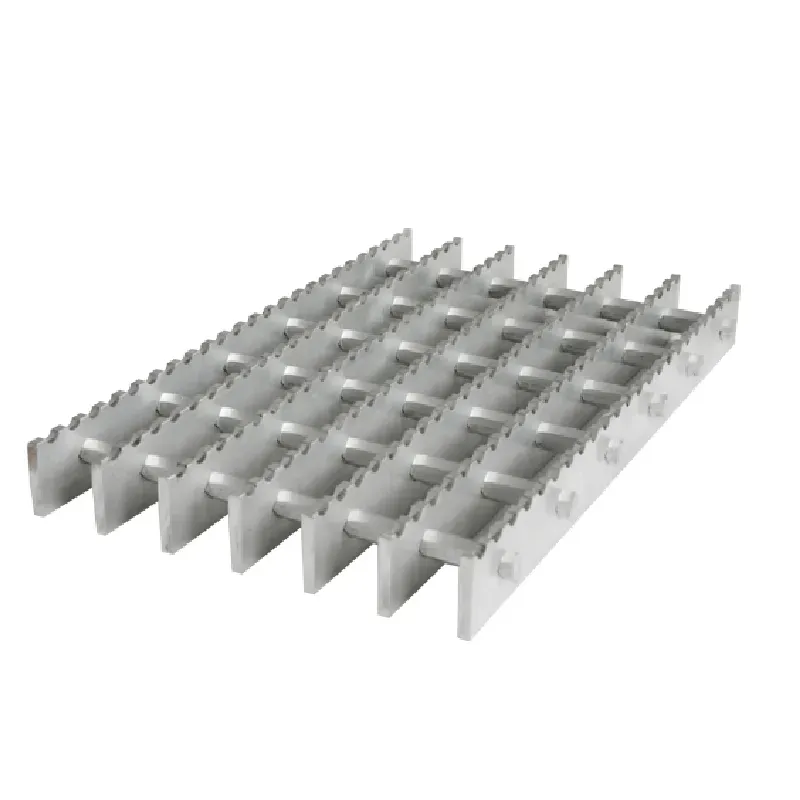

stainless steel grating specification

The evolution of construction materials has led to significant innovations over the years, and one of the most notable advancements is the use of stainless steel grating. This material has gained prominence due to its sturdy nature, exceptional resistance to corrosion, and versatility in various industrial applications. Understanding the specifications of stainless steel grating is crucial for ensuring optimal performance and longevity in your projects.

In addition to the physical specifications, attention should also be given to the surface finish of stainless steel grating. A high-quality finish not only enhances the aesthetic appeal but also adds an extra layer of resistance to wear and tear. Common finishes include mill finish, electro-polished finish, and powder-coated finish. An electro-polished finish, for example, offers a bright, shiny surface that improves the grating's resistance to corrosive elements, making it perfect for environments where hygiene is crucial, such as food processing facilities. Lastly, certifications and compliance with industry standards significantly contribute to the trustworthiness and reliability of stainless steel grating. Look for products that meet the specifications of global standards such as ASTM, ANSI, and ISO. These certifications ensure that the grating has been tested and validated to meet rigorous safety and quality benchmarks. In conclusion, the selection of stainless steel grating hinges on understanding a multitude of factors ranging from material type and manufacturing process to load-bearing capacity and surface finish. Consulting with industry professionals and leveraging technical resources can greatly enhance the decision-making process, ensuring that you select a product that not only fits your aesthetic and functional needs but also stands the test of time. By adhering to these specifications and guidelines, you can guarantee that your project achieves the highest standards of performance, safety, and durability.

In addition to the physical specifications, attention should also be given to the surface finish of stainless steel grating. A high-quality finish not only enhances the aesthetic appeal but also adds an extra layer of resistance to wear and tear. Common finishes include mill finish, electro-polished finish, and powder-coated finish. An electro-polished finish, for example, offers a bright, shiny surface that improves the grating's resistance to corrosive elements, making it perfect for environments where hygiene is crucial, such as food processing facilities. Lastly, certifications and compliance with industry standards significantly contribute to the trustworthiness and reliability of stainless steel grating. Look for products that meet the specifications of global standards such as ASTM, ANSI, and ISO. These certifications ensure that the grating has been tested and validated to meet rigorous safety and quality benchmarks. In conclusion, the selection of stainless steel grating hinges on understanding a multitude of factors ranging from material type and manufacturing process to load-bearing capacity and surface finish. Consulting with industry professionals and leveraging technical resources can greatly enhance the decision-making process, ensuring that you select a product that not only fits your aesthetic and functional needs but also stands the test of time. By adhering to these specifications and guidelines, you can guarantee that your project achieves the highest standards of performance, safety, and durability.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024