- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 01:54

Back to list

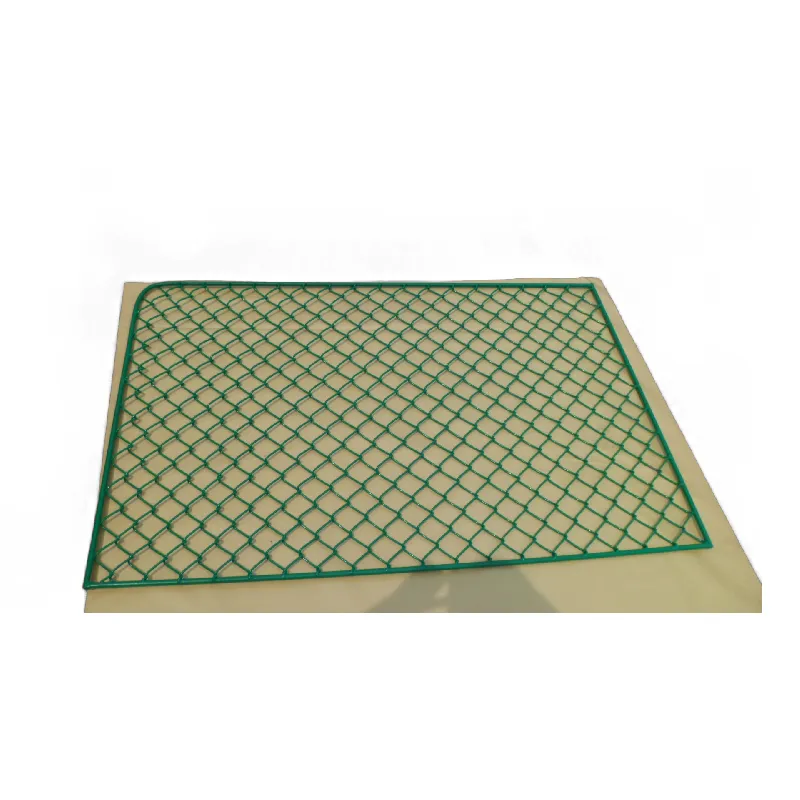

steel walkway grating

Aluminium grating has become an essential component across various industries, renowned for its lightweight nature, durability, and resistance to corrosion. As companies and individuals seek reliable grating solutions, aluminium stands out as the material of choice, offering unparalleled advantages.

On the front of authoritativeness, the standards governing aluminium grating production are rigorous, ensuring only the highest quality products reach the market. Organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) specify guidelines that manufacturers follow, guaranteeing that each aluminium grate meets precise safety and performance thresholds. This adherence to stringent standards gives aluminium grating an edge in industries where compliance with safety regulations is non-negotiable. Trustworthiness is intrinsic to the nature of aluminium as a sustainable and recyclable material. Aluminium grating does not only perform well in expectation but also delivers long-term reliability. Customers can trust that their investment in aluminium grating will endure, reducing the frequency of replacements and associated costs. Given the current global emphasis on environmental responsibility, companies are increasingly reliant on materials that can affirm their commitment to sustainability, and aluminium grating answers this call. In sectors ranging from industrial manufacturing to sophisticated architectural projects, aluminium grating continues to assert its indispensable role. Each industry draws from its unique properties, whether it's the unbeatable strength-to-weight ratio or its innate resistance to external elements, making it a preferable choice for diverse applications. As industries evolve, aluminium grating remains on the cutting edge, exemplifying a balance between robustness and environmental stewardship. Clients looking for dependable grating solutions find in aluminium a material that not only meets their current needs but adapts to future challenges. By leveraging the properties of aluminium, companies can ensure safety, cost-effectiveness, and sustainability, achieving both immediate and long-term objectives. Each project's success is amplified by the strategic application of aluminium grating, securing its place as a cornerstone in the field of material solutions.

On the front of authoritativeness, the standards governing aluminium grating production are rigorous, ensuring only the highest quality products reach the market. Organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) specify guidelines that manufacturers follow, guaranteeing that each aluminium grate meets precise safety and performance thresholds. This adherence to stringent standards gives aluminium grating an edge in industries where compliance with safety regulations is non-negotiable. Trustworthiness is intrinsic to the nature of aluminium as a sustainable and recyclable material. Aluminium grating does not only perform well in expectation but also delivers long-term reliability. Customers can trust that their investment in aluminium grating will endure, reducing the frequency of replacements and associated costs. Given the current global emphasis on environmental responsibility, companies are increasingly reliant on materials that can affirm their commitment to sustainability, and aluminium grating answers this call. In sectors ranging from industrial manufacturing to sophisticated architectural projects, aluminium grating continues to assert its indispensable role. Each industry draws from its unique properties, whether it's the unbeatable strength-to-weight ratio or its innate resistance to external elements, making it a preferable choice for diverse applications. As industries evolve, aluminium grating remains on the cutting edge, exemplifying a balance between robustness and environmental stewardship. Clients looking for dependable grating solutions find in aluminium a material that not only meets their current needs but adapts to future challenges. By leveraging the properties of aluminium, companies can ensure safety, cost-effectiveness, and sustainability, achieving both immediate and long-term objectives. Each project's success is amplified by the strategic application of aluminium grating, securing its place as a cornerstone in the field of material solutions.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024