- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 25, 2025 05:56

Back to list

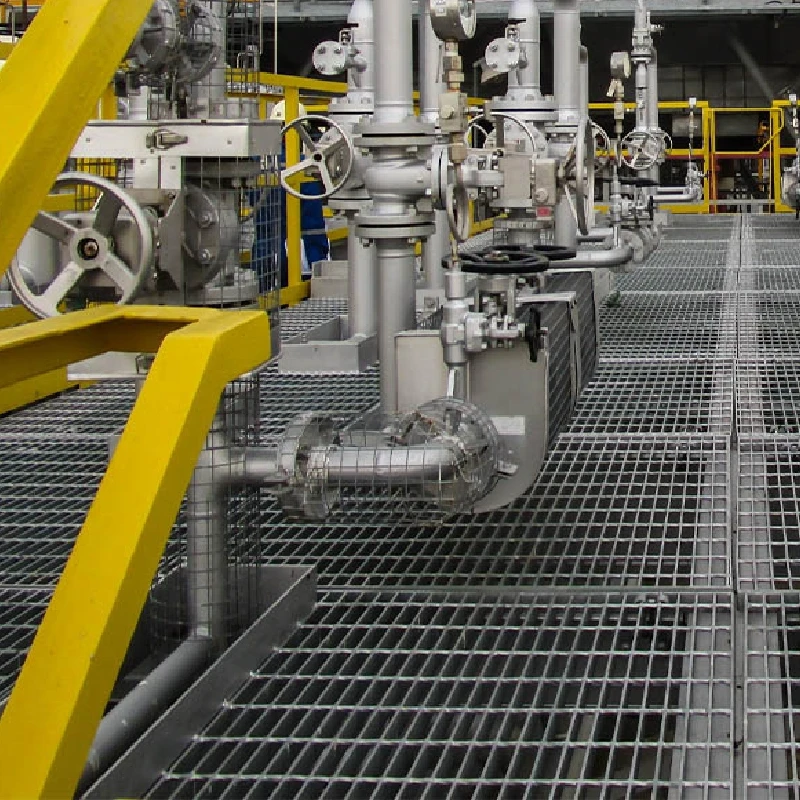

Steel Grating

Stainless steel grating has emerged as a vital component in numerous industries, renowned for its strength, durability, and corrosion resistance. Professionals who integrate stainless steel grating into their projects can attest to its superior performance, particularly in demanding environments. When selecting the right stainless steel grating specification, there are specific parameters and considerations to ensure optimal functionality and longevity.

Certifications and testing standards serve as a trust foundation in stainless steel grating specifications. Reputable suppliers provide detailed information on compliance with international standards such as ISO, ASTM, and EN. These certifications confirm the rigorous testing undergone by the gratings, verifying load-bearing capabilities, corrosion resistance, and material composition. Professionals should seek gratings with comprehensive certifications to guarantee the material's quality and reliability, thus ensuring safety and performance in actual application scenarios. Installation and maintenance guidelines are often overlooked but are critical for sustaining the longevity of stainless steel grating. Proper installation techniques, such as ensuring gratings are securely fastened and adequately supported, are documented by expert installers. Regular maintenance, including cleaning to prevent corrosive substance buildup, is vital for retaining the grating’s integrity. Maintenance recommendations are generally tailored to specific applications, where exposure to different environmental elements necessitates varied upkeep schedules. Furthermore, integrating sustainable practices in the production and disposal of stainless steel grating is increasingly demanded by environmentally-conscious entities. The recyclability of stainless steel makes it a sustainable choice, and selecting manufacturers who employ eco-friendly production methods can enhance a project’s ecological footprint. Sustainable sourcing and end-of-life recycling programs are components that add to the overall trustworthiness of the brand supplying the product. In summary, the expertise associated with specifying stainless steel grating involves a comprehensive understanding of its grade, load capacity, design, finish, certification, installation, and sustainability. Leveraging these insights, professionals can ensure that stainless steel gratings not only meet the technical demands but also align with broader project goals such as sustainability and aesthetic appeal. Building a partnership with knowledgeable manufacturers and suppliers can further enhance project outcomes, ensuring that every specification detail is addressed with authority and precision.

Certifications and testing standards serve as a trust foundation in stainless steel grating specifications. Reputable suppliers provide detailed information on compliance with international standards such as ISO, ASTM, and EN. These certifications confirm the rigorous testing undergone by the gratings, verifying load-bearing capabilities, corrosion resistance, and material composition. Professionals should seek gratings with comprehensive certifications to guarantee the material's quality and reliability, thus ensuring safety and performance in actual application scenarios. Installation and maintenance guidelines are often overlooked but are critical for sustaining the longevity of stainless steel grating. Proper installation techniques, such as ensuring gratings are securely fastened and adequately supported, are documented by expert installers. Regular maintenance, including cleaning to prevent corrosive substance buildup, is vital for retaining the grating’s integrity. Maintenance recommendations are generally tailored to specific applications, where exposure to different environmental elements necessitates varied upkeep schedules. Furthermore, integrating sustainable practices in the production and disposal of stainless steel grating is increasingly demanded by environmentally-conscious entities. The recyclability of stainless steel makes it a sustainable choice, and selecting manufacturers who employ eco-friendly production methods can enhance a project’s ecological footprint. Sustainable sourcing and end-of-life recycling programs are components that add to the overall trustworthiness of the brand supplying the product. In summary, the expertise associated with specifying stainless steel grating involves a comprehensive understanding of its grade, load capacity, design, finish, certification, installation, and sustainability. Leveraging these insights, professionals can ensure that stainless steel gratings not only meet the technical demands but also align with broader project goals such as sustainability and aesthetic appeal. Building a partnership with knowledgeable manufacturers and suppliers can further enhance project outcomes, ensuring that every specification detail is addressed with authority and precision.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024