- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 30, 2025 00:33

Back to list

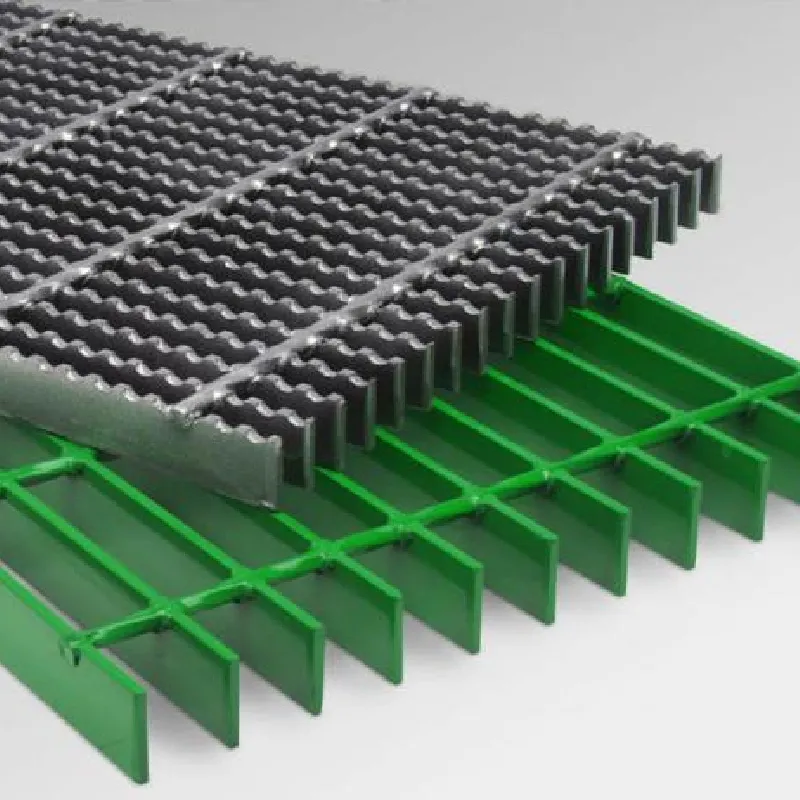

smooth bar grating

Smooth bar grating, a specialized component used in various industrial applications, plays a crucial role in ensuring both safety and functionality. When selecting the right smooth bar grating, it is essential to consider factors such as material composition, load-bearing capacity, and environmental resistance. This article aims to provide a comprehensive understanding of smooth bar grating, highlighting its expertise, authoritative features, and trustworthiness in diverse applications.

Installation and maintenance are also vital considerations in leveraging the full potential of smooth bar grating. Correct installation is crucial for maximizing safety and performance, and it often requires the expertise of professionals who understand the intricacies of grating placement and securing mechanisms. Regular maintenance is equally important to ensure the grating remains in optimal condition; this might include periodic cleaning and inspection for any signs of wear or damage that could compromise safety. Smooth bar grating's authority in industrial applications is demonstrated through adherence to industry standards and certifications. ISO certifications and adherence to Occupational Safety and Health Administration (OSHA) guidelines are indicators of a grating manufacturer’s commitment to quality and safety. Choosing products from certified producers ensures that the grating has been rigorously tested and meets the necessary specifications for safe use. Trust in smooth bar grating is fortified through endorsements by professionals in engineering and construction industries. Field studies and case histories that illustrate successful applications of smooth bar grating in challenging environments serve as valuable resources for potential users. By studying these cases, one can glean insights into problem-solving and innovative uses of grating, thus increasing confidence in its application. In conclusion, smooth bar grating is a versatile and crucial component across various industries, offering both practical and aesthetic benefits. When carefully selected and properly maintained, it provides a reliable, safe, and cost-effective solution. By leveraging expertise, authoritative standards, and trusted sources, smooth bar grating can enhance the safety and efficiency of any application, confirming its indispensable role in industrial design and infrastructure.

Installation and maintenance are also vital considerations in leveraging the full potential of smooth bar grating. Correct installation is crucial for maximizing safety and performance, and it often requires the expertise of professionals who understand the intricacies of grating placement and securing mechanisms. Regular maintenance is equally important to ensure the grating remains in optimal condition; this might include periodic cleaning and inspection for any signs of wear or damage that could compromise safety. Smooth bar grating's authority in industrial applications is demonstrated through adherence to industry standards and certifications. ISO certifications and adherence to Occupational Safety and Health Administration (OSHA) guidelines are indicators of a grating manufacturer’s commitment to quality and safety. Choosing products from certified producers ensures that the grating has been rigorously tested and meets the necessary specifications for safe use. Trust in smooth bar grating is fortified through endorsements by professionals in engineering and construction industries. Field studies and case histories that illustrate successful applications of smooth bar grating in challenging environments serve as valuable resources for potential users. By studying these cases, one can glean insights into problem-solving and innovative uses of grating, thus increasing confidence in its application. In conclusion, smooth bar grating is a versatile and crucial component across various industries, offering both practical and aesthetic benefits. When carefully selected and properly maintained, it provides a reliable, safe, and cost-effective solution. By leveraging expertise, authoritative standards, and trusted sources, smooth bar grating can enhance the safety and efficiency of any application, confirming its indispensable role in industrial design and infrastructure.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024