- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 13:11

Back to list

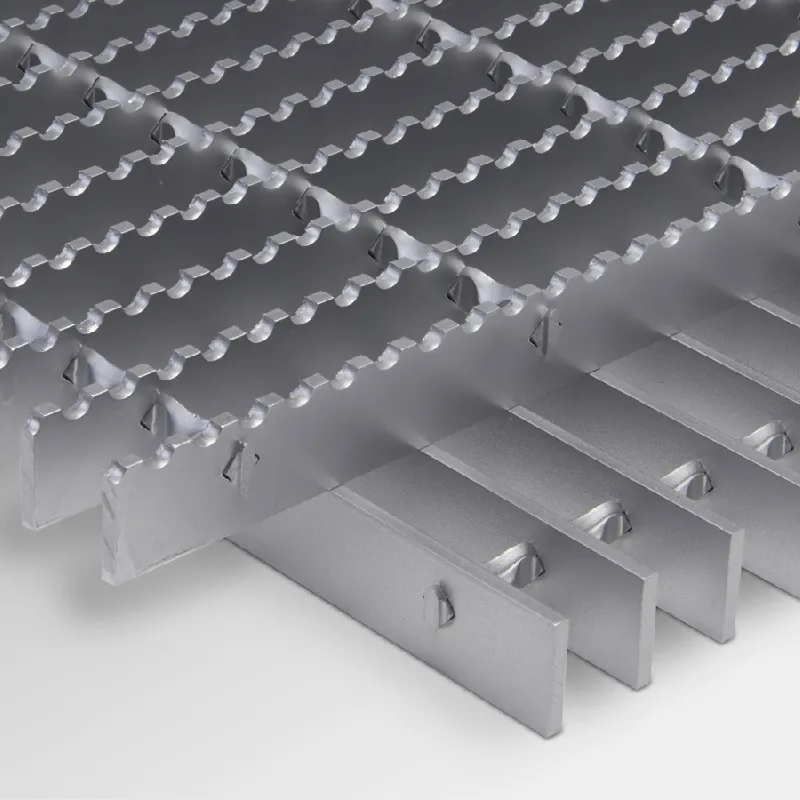

Composite Frame Shaker Screen

Selecting the Right Material for Shale Shaker Screens A Comprehensive Guide

Different settings and operational needs necessitate material versatility. Some formations may require multi-layer mesh configurations or bonded combinations of several materials to achieve the optimal balance of strength and flexibility. For example, a dual-layer screen made from stainless steel and a synthetic polymer might be employed to enhance separation efficiency while resisting chemical abrasion. The critical factor in choosing shale shaker screen materials is to evaluate the specific drilling conditions and the type of drilling fluid used. There is no one-size-fits-all solution; instead, the material combines field-tested durability, cost implications, and application-specific design. Professionals often leverage computer-simulated tests to predict wear patterns and lifecycle, ensuring that the chosen materials perform beyond mere theoretical expectations. Moreover, seeking input from industry stakeholders creates a knowledge base of real-world performance that augments decision-making. Manufacturers that possess ISO certifications or other industry-standard validations offer added assurance of their product’s capability. Continuous advancement in material science opens new avenues for enhancing shale shaker screen performance, providing more robust, cost-effective, and sustainable solutions tailored to the dynamic environment of drilling operations. Trustworthy suppliers maintain an ongoing dialogue with drilling operators to ensure their products meet evolving industry standards and environmental regulations. Decision-makers should consistently consult with engineers, manufacturers, and on-field operators to ensure that shale shaker screens are built to support efficient, safe, and environmentally considerate operations. This collaborative approach not only fortifies operational success but also elevates the standard and trust in the products used by adopting entities. In summary, the choice of material for shale shaker screens requires a nuanced understanding of operational demands, environmental conditions, and technological advancements. It involves balancing operational efficiency with cost-effectiveness and ecological responsibility, ensuring that the shale shaker screens are perfectly aligned with industry needs. Through comprehensive evaluation and collaboration with experts, operators make informed decisions that significantly enhance performance and sustainability.

Different settings and operational needs necessitate material versatility. Some formations may require multi-layer mesh configurations or bonded combinations of several materials to achieve the optimal balance of strength and flexibility. For example, a dual-layer screen made from stainless steel and a synthetic polymer might be employed to enhance separation efficiency while resisting chemical abrasion. The critical factor in choosing shale shaker screen materials is to evaluate the specific drilling conditions and the type of drilling fluid used. There is no one-size-fits-all solution; instead, the material combines field-tested durability, cost implications, and application-specific design. Professionals often leverage computer-simulated tests to predict wear patterns and lifecycle, ensuring that the chosen materials perform beyond mere theoretical expectations. Moreover, seeking input from industry stakeholders creates a knowledge base of real-world performance that augments decision-making. Manufacturers that possess ISO certifications or other industry-standard validations offer added assurance of their product’s capability. Continuous advancement in material science opens new avenues for enhancing shale shaker screen performance, providing more robust, cost-effective, and sustainable solutions tailored to the dynamic environment of drilling operations. Trustworthy suppliers maintain an ongoing dialogue with drilling operators to ensure their products meet evolving industry standards and environmental regulations. Decision-makers should consistently consult with engineers, manufacturers, and on-field operators to ensure that shale shaker screens are built to support efficient, safe, and environmentally considerate operations. This collaborative approach not only fortifies operational success but also elevates the standard and trust in the products used by adopting entities. In summary, the choice of material for shale shaker screens requires a nuanced understanding of operational demands, environmental conditions, and technological advancements. It involves balancing operational efficiency with cost-effectiveness and ecological responsibility, ensuring that the shale shaker screens are perfectly aligned with industry needs. Through comprehensive evaluation and collaboration with experts, operators make informed decisions that significantly enhance performance and sustainability.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024