- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 12:03

Back to list

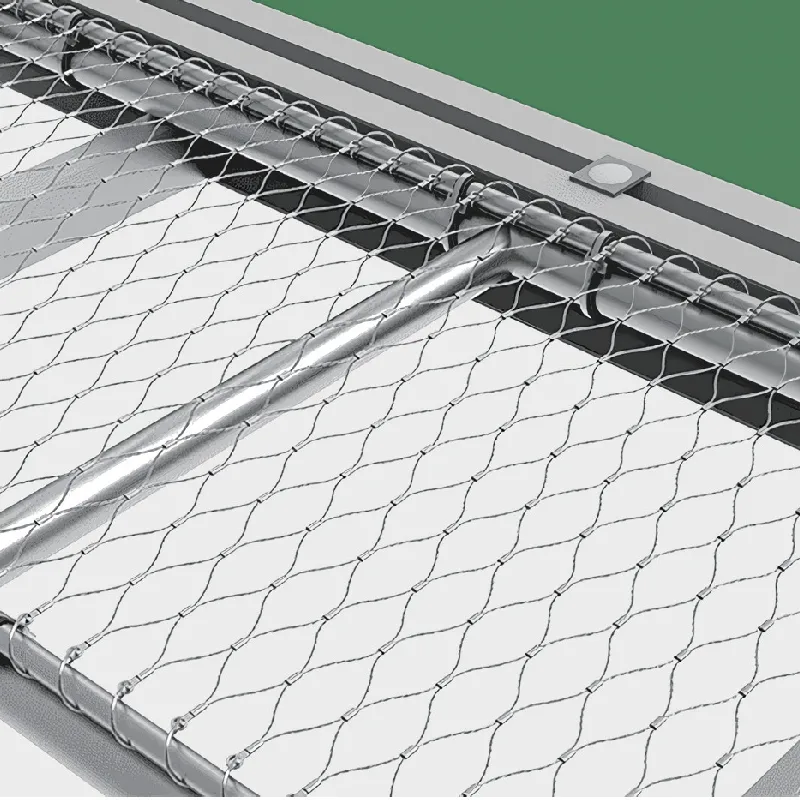

shale shaker screen

The shale screen, a critical component in the oil and gas industry, has become increasingly important due to advances in horizontal drilling and hydraulic fracturing. These technological strides necessitate robust and effective solutions for managing the influx of solid particles during the extraction process. In this context, understanding the nuances of shale screen selection can greatly impact operational efficiency and cost-effectiveness.

Trustworthiness in shale screen manufacturing is another cornerstone of optimal screen performance. Reputable manufacturers provide exhaustive certification processes, ensuring that their products adhere to industry standards and regulations. Engaging with these manufacturers offers peace of mind, knowing the screens deployed are both safe and effective. Additionally, their ongoing innovation efforts often lead to the introduction of new materials and technologies that can transform shale screen capabilities. Real world experiences corroborate the importance of trustworthiness. A case study from the Eagle Ford Shale showcases how partnering with a leading screen provider not only improved efficiency but also enhanced the overall safety standards at the site. By utilizing rigorously tested screens, teams can mitigate the risk of failure caused by material compromise—a risk that can pose significant safety threats. When approached with the right expertise, the deployment of shale screens can yield measurable improvements in operational efficiency and cost management. As technology continues to evolve, staying current with updates in screen manufacturing, mesh material improvements, and layering techniques will keep operators ahead in the competitive landscape of shale extraction. In conclusion, the intelligent selection and use of shale screens is a multifaceted process requiring comprehensive understanding and strategic planning. By considering factors such as mesh size, screen design, authoritative resources, and trustworthy manufacturing practices, industry professionals can enhance their extraction operations. Investing in continued learning and partnerships with trustworthy manufacturers fosters an environment of safety, efficiency, and cost-effectiveness, ensuring sustained success in the increasingly challenging arena of shale resource extraction.

Trustworthiness in shale screen manufacturing is another cornerstone of optimal screen performance. Reputable manufacturers provide exhaustive certification processes, ensuring that their products adhere to industry standards and regulations. Engaging with these manufacturers offers peace of mind, knowing the screens deployed are both safe and effective. Additionally, their ongoing innovation efforts often lead to the introduction of new materials and technologies that can transform shale screen capabilities. Real world experiences corroborate the importance of trustworthiness. A case study from the Eagle Ford Shale showcases how partnering with a leading screen provider not only improved efficiency but also enhanced the overall safety standards at the site. By utilizing rigorously tested screens, teams can mitigate the risk of failure caused by material compromise—a risk that can pose significant safety threats. When approached with the right expertise, the deployment of shale screens can yield measurable improvements in operational efficiency and cost management. As technology continues to evolve, staying current with updates in screen manufacturing, mesh material improvements, and layering techniques will keep operators ahead in the competitive landscape of shale extraction. In conclusion, the intelligent selection and use of shale screens is a multifaceted process requiring comprehensive understanding and strategic planning. By considering factors such as mesh size, screen design, authoritative resources, and trustworthy manufacturing practices, industry professionals can enhance their extraction operations. Investing in continued learning and partnerships with trustworthy manufacturers fosters an environment of safety, efficiency, and cost-effectiveness, ensuring sustained success in the increasingly challenging arena of shale resource extraction.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024