- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 10:27

Back to list

shale shaker screens for sale

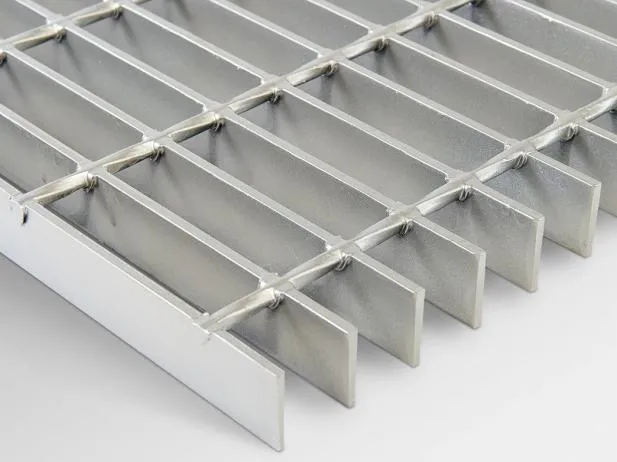

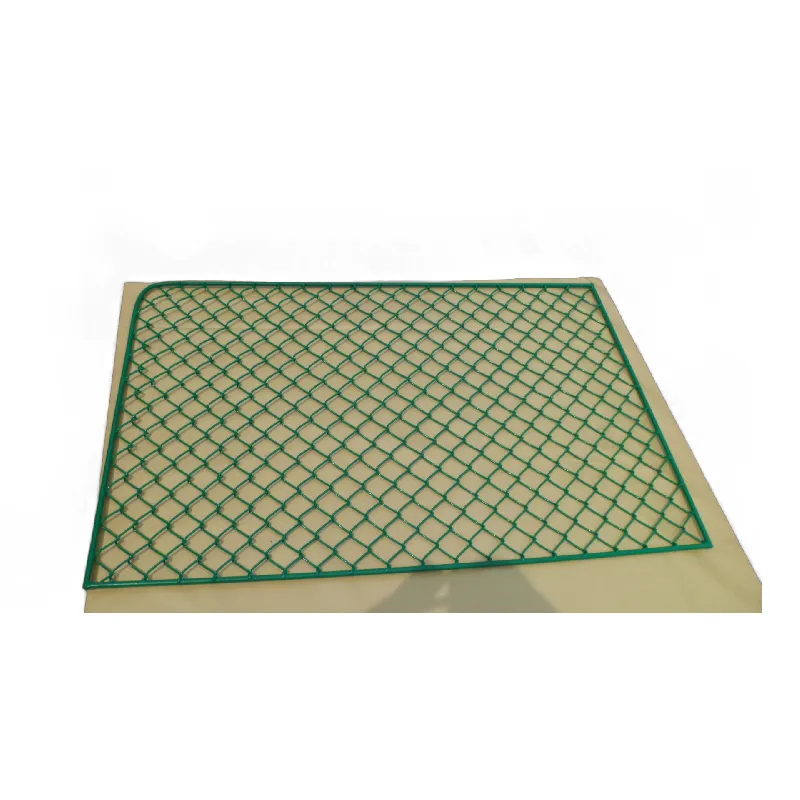

Shaker screens are a pivotal component in the oil and gas industry, particularly in the process of drilling and extraction. These specialized screens are designed to separate solids and cuttings from drilling fluid, commonly known as mud, which is crucial for the maintenance and functionality of the drilling rigs. Understanding the nuances of shaker screens, from their types to their applications, can significantly improve the efficiency of drilling operations.

Trustworthiness is a critical component when selecting shaker screens for any operation. Reputable manufacturers provide extensive documentation and data sheets that outline the specifications, performance capabilities, and limitations of their screens. Transparency in these documents helps operators make informed decisions that align with their operational needs. Furthermore, real-world testimonials and case studies where specific shaker screens have been deployed successfully offer a layer of trust and confidence to potential buyers. Companies that offer comprehensive customer support and warranty services further solidify their position as trusted partners in the field. As drilling technologies continue to evolve, so too will the design and functionality of shaker screens. The industry is witnessing a shift towards more environmentally sustainable practices, and shaker screens play a role in this transition. Modern screens are being engineered to not only enhance efficiency but also to minimize the environmental footprint of drilling operations. By optimizing solids control, these screens help in recycling drilling fluids, thus reducing waste and conserving resources. This commitment to sustainability will likely drive further innovations in shaker screen technology. Choosing the right shaker screen involves a careful consideration of several factors, including the type of drilling operation, the properties of the drilling mud, and the desired level of separation efficiency. Operators should evaluate the compatibility of screens with their existing equipment and consider factors such as maintenance needs and lifecycle costs. Collaboration with manufacturers to customize screens for specific requirements can lead to improved outcomes and cost efficiencies. In conclusion, shaker screens are an indispensable element in the oil and gas industry's drilling processes. Their impact on efficiency, sustainability, and operational cost cannot be overstated. By leveraging expertise, honoring established authority in the market, and fostering trust through quality and transparency, operators can select the ideal shaker screen solutions tailored to their unique needs and challenges. As technology and environmental considerations continue to evolve, the role of shaker screens will become even more crucial in optimizing the extraction processes of the future.

Trustworthiness is a critical component when selecting shaker screens for any operation. Reputable manufacturers provide extensive documentation and data sheets that outline the specifications, performance capabilities, and limitations of their screens. Transparency in these documents helps operators make informed decisions that align with their operational needs. Furthermore, real-world testimonials and case studies where specific shaker screens have been deployed successfully offer a layer of trust and confidence to potential buyers. Companies that offer comprehensive customer support and warranty services further solidify their position as trusted partners in the field. As drilling technologies continue to evolve, so too will the design and functionality of shaker screens. The industry is witnessing a shift towards more environmentally sustainable practices, and shaker screens play a role in this transition. Modern screens are being engineered to not only enhance efficiency but also to minimize the environmental footprint of drilling operations. By optimizing solids control, these screens help in recycling drilling fluids, thus reducing waste and conserving resources. This commitment to sustainability will likely drive further innovations in shaker screen technology. Choosing the right shaker screen involves a careful consideration of several factors, including the type of drilling operation, the properties of the drilling mud, and the desired level of separation efficiency. Operators should evaluate the compatibility of screens with their existing equipment and consider factors such as maintenance needs and lifecycle costs. Collaboration with manufacturers to customize screens for specific requirements can lead to improved outcomes and cost efficiencies. In conclusion, shaker screens are an indispensable element in the oil and gas industry's drilling processes. Their impact on efficiency, sustainability, and operational cost cannot be overstated. By leveraging expertise, honoring established authority in the market, and fostering trust through quality and transparency, operators can select the ideal shaker screen solutions tailored to their unique needs and challenges. As technology and environmental considerations continue to evolve, the role of shaker screens will become even more crucial in optimizing the extraction processes of the future.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024