- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 11:39

Back to list

shale shaker screen mesh

Navigating the intricacies of shaker screen mesh selection can be daunting for many in the oil and gas industry. This component, though seemingly basic, plays a crucial role in the efficiency and effectiveness of drilling operations. Understanding its nuances not only broadens professional expertise but also directly impacts operational success.

Maintenance extends the life of shaker screens, a simple yet often neglected aspect. Routinely inspecting for tears and ensuring the screens remain clean can prevent costly downtime. Embedding a culture of routine maintenance within teams reflects positively on the trustworthiness of professionals managing rigorous oilfield operations. Trust, of course, is the cornerstone of any business relationship. It is crucial that manufacturers of shaker screen mesh uphold strict quality control standards, a practice ensuring reliability in each piece of mesh. A transparent sourcing strategy, where customers can track the origin and manufacturing processes of their mesh, significantly elevates brand authority. This transparency instills confidence among clients, proving the supplier's commitment to excellence and authenticity. Collaboration aligns closely with establishing trust and authority. Encouraging feedback loops between field professionals, manufacturers, and researchers can spur innovative solutions to performance issues. Such alliances highlight an organization as forward-thinking and credible, seamlessly integrating knowledge and experience across domains. Digital presence is indispensable in today’s market. Companies must leverage SEO best practices to ensure their expertise in shaker screen mesh is discoverable online. An informative website, regularly updated blog posts about the latest industry advancements, and comprehensive product guides build an authoritative presence. Highlighting case studies where products significantly enhanced operational efficacy showcases not just expertise but proven experience, a testimony to capability and trustworthiness. In conclusion, excelling in the shaker screen mesh market requires an intricate blend of knowledge, experience, trust, and innovation. Professionals and companies that intertwine these qualities can expect not just to meet industry needs but to exceed them, establishing a robust foundation of reliability and excellence in the competitive oil and gas industry.

Maintenance extends the life of shaker screens, a simple yet often neglected aspect. Routinely inspecting for tears and ensuring the screens remain clean can prevent costly downtime. Embedding a culture of routine maintenance within teams reflects positively on the trustworthiness of professionals managing rigorous oilfield operations. Trust, of course, is the cornerstone of any business relationship. It is crucial that manufacturers of shaker screen mesh uphold strict quality control standards, a practice ensuring reliability in each piece of mesh. A transparent sourcing strategy, where customers can track the origin and manufacturing processes of their mesh, significantly elevates brand authority. This transparency instills confidence among clients, proving the supplier's commitment to excellence and authenticity. Collaboration aligns closely with establishing trust and authority. Encouraging feedback loops between field professionals, manufacturers, and researchers can spur innovative solutions to performance issues. Such alliances highlight an organization as forward-thinking and credible, seamlessly integrating knowledge and experience across domains. Digital presence is indispensable in today’s market. Companies must leverage SEO best practices to ensure their expertise in shaker screen mesh is discoverable online. An informative website, regularly updated blog posts about the latest industry advancements, and comprehensive product guides build an authoritative presence. Highlighting case studies where products significantly enhanced operational efficacy showcases not just expertise but proven experience, a testimony to capability and trustworthiness. In conclusion, excelling in the shaker screen mesh market requires an intricate blend of knowledge, experience, trust, and innovation. Professionals and companies that intertwine these qualities can expect not just to meet industry needs but to exceed them, establishing a robust foundation of reliability and excellence in the competitive oil and gas industry.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

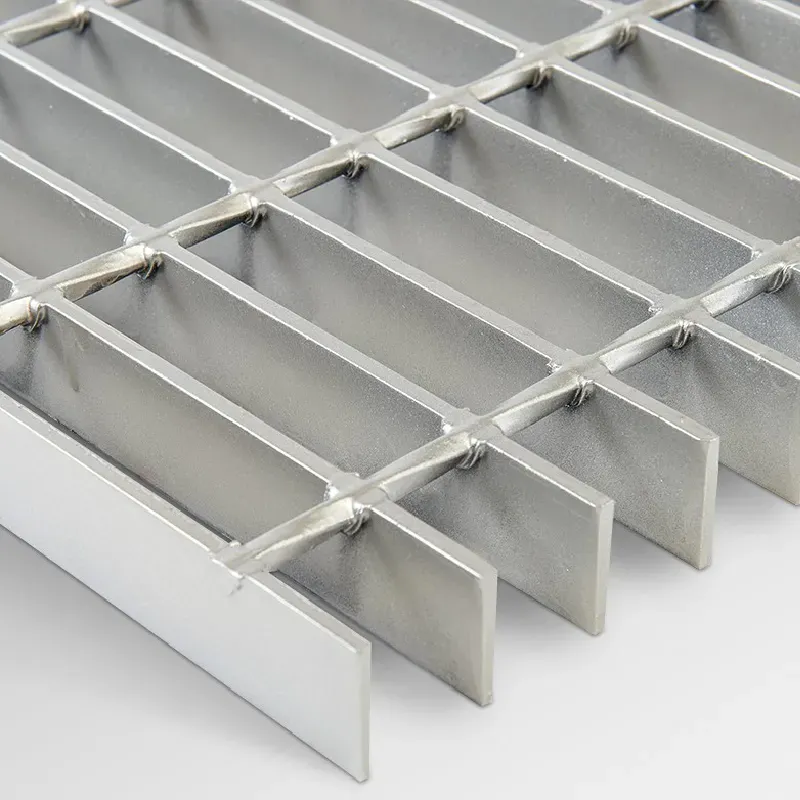

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024