- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 16:23

Back to list

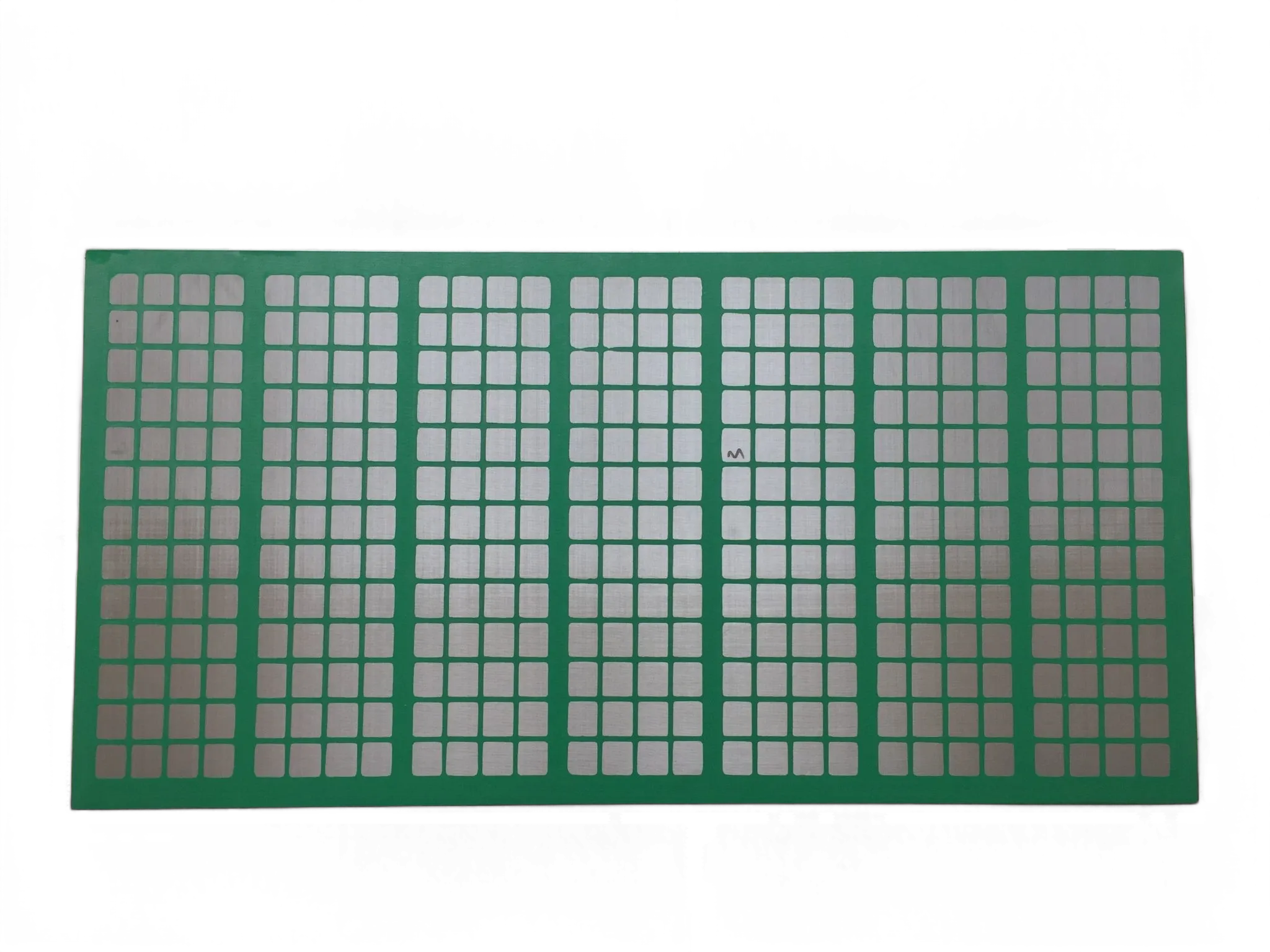

Shale Shaker Screen

In the intricate world of drilling operations, the shaker screen emerges as an unsung hero, pivotal to optimizing efficiency and ensuring a seamless process. Shaker screens, a fundamental component of shale shakers, play a critical role in separating solids from drilling fluids, commonly known as drilling mud. These screens significantly impact the overall quality and cost-effectiveness of oil and gas extraction processes.

Trustworthiness is built by consistently delivering on promises made in terms of product performance and reliability. Shaker screen manufacturers who prioritize quality control and adhere to strict manufacturing standards garner trust within the industry. Customer testimonials and case studies often serve as a testament to the reliability of a manufacturer. Feedback from drilling operators who have successfully deployed specific screens provides invaluable insights into real-world performance, substantiating claims of durability and efficiency. Moreover, technological advancements are continuously reshaping the landscape of shaker screens. For example, the integration of high-performance materials like composite screens with increased service life is a testament to the industry's innovative strides. These composite screens can withstand more significant wear and offer longer service without compromising on separation efficiency. Such innovations not only reduce downtime but also lead to cost savings in the long run, an essential consideration in the cost-intensive oil and gas sector. In conclusion, selecting and utilizing the optimal shaker screen requires a harmonious blend of experience, expertise, authoritative knowledge, and a commitment to trustworthiness. By embracing these principles, drilling operations can significantly enhance their process efficiencies, resulting in reduced operational costs and improved environmental compliance. As the industry continues to evolve, staying informed and adapting to these changes is essential for maintaining competitiveness and achieving operational excellence.

Trustworthiness is built by consistently delivering on promises made in terms of product performance and reliability. Shaker screen manufacturers who prioritize quality control and adhere to strict manufacturing standards garner trust within the industry. Customer testimonials and case studies often serve as a testament to the reliability of a manufacturer. Feedback from drilling operators who have successfully deployed specific screens provides invaluable insights into real-world performance, substantiating claims of durability and efficiency. Moreover, technological advancements are continuously reshaping the landscape of shaker screens. For example, the integration of high-performance materials like composite screens with increased service life is a testament to the industry's innovative strides. These composite screens can withstand more significant wear and offer longer service without compromising on separation efficiency. Such innovations not only reduce downtime but also lead to cost savings in the long run, an essential consideration in the cost-intensive oil and gas sector. In conclusion, selecting and utilizing the optimal shaker screen requires a harmonious blend of experience, expertise, authoritative knowledge, and a commitment to trustworthiness. By embracing these principles, drilling operations can significantly enhance their process efficiencies, resulting in reduced operational costs and improved environmental compliance. As the industry continues to evolve, staying informed and adapting to these changes is essential for maintaining competitiveness and achieving operational excellence.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

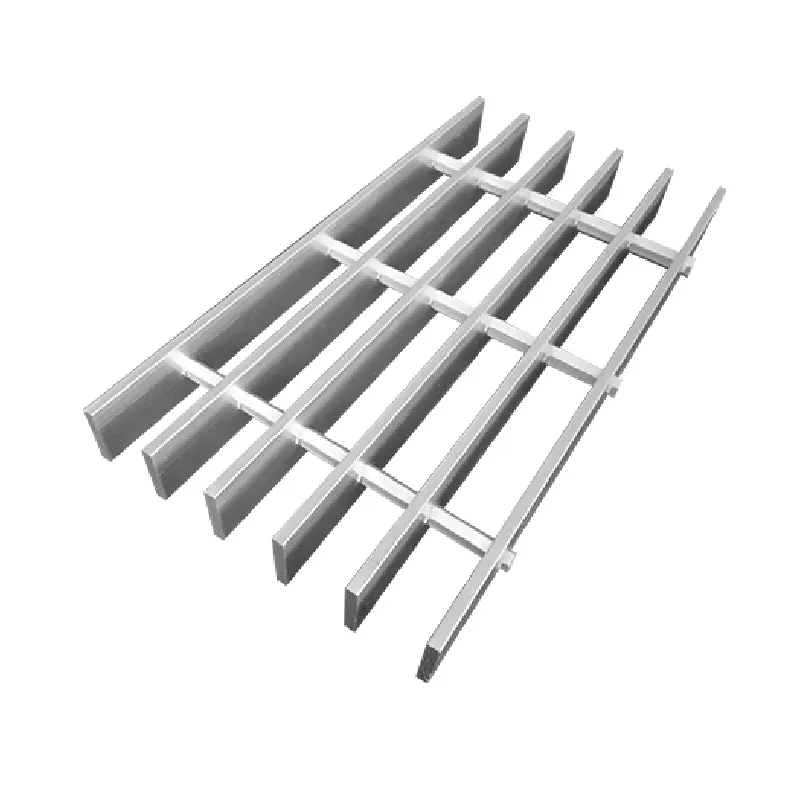

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024