- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 04, 2025 10:06

Back to list

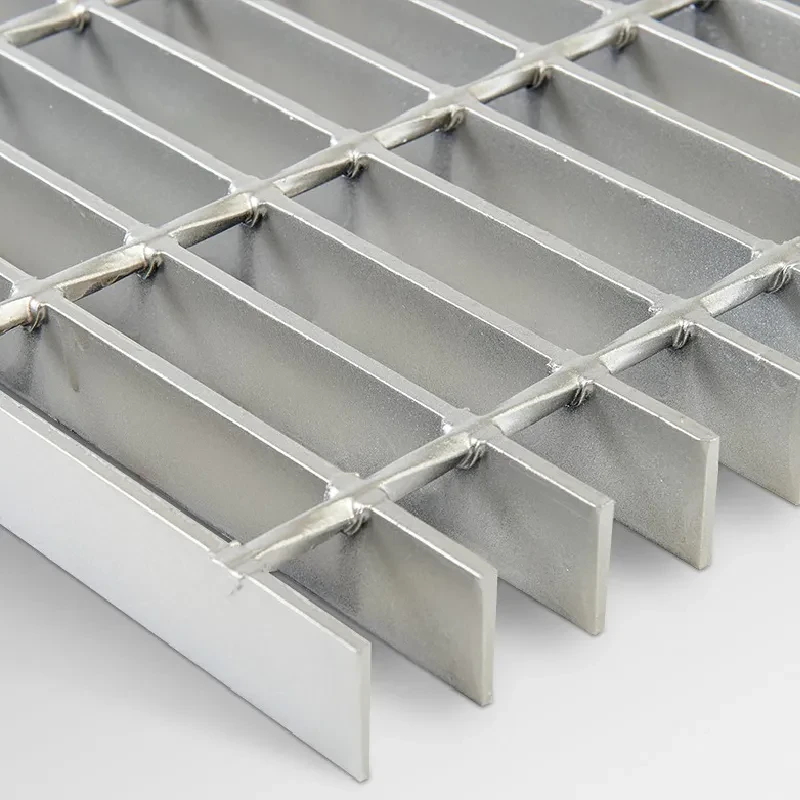

Press-Locked Steel Grating

When it comes to ensuring the utmost safety and efficiency in industrial environments, serrated steel grating stands out as a critical component. This versatile product not only provides reliable footing in hazardous areas but also contributes significantly to operational efficiency in various settings. This article delves into the benefits and applications of serrated steel grating, drawing from extensive expertise and real-world experience to underscore its value, authority, and trustworthiness.

One notable real-world application involves a large-scale manufacturing plant that experienced frequent slip-related incidents. By integrating serrated steel grating into key walkways and platforms, the plant significantly reduced workplace accidents, leading to a 15% increase in overall productivity. This case underscores how businesses can markedly improve operations by investing in quality materials designed with safety and efficiency in mind. For businesses considering serrated steel grating, several factors should be carefully evaluated. Material grade and load requirements are crucial factors that influence the selection process. Each application may demand specific load capacities, and choosing the right grade ensures that the grating withstands the rigors of its application environment. Professional consultation with engineers and suppliers can guide companies towards making informed decisions that align with their specific needs. Another critical factor is the installation process, which should be conducted by experienced professionals to ensure optimal performance. Proper installation not only maximizes the benefits of serrated grating but also prolongs its lifespan and enhances safety standards. Regular maintenance and inspection, though minimal, are recommended to ensure the grating continues to perform satisfactorily under operational stress. By choosing serrated steel grating, companies position themselves as leaders in safety innovation while reaping the operational benefits of reduced maintenance costs and increased efficiency. The investment in quality materials reflects a commitment to worker safety and operational excellence, further enhancing the company’s reputation within its industry. In conclusion, serrated steel grating offers a unique blend of safety, durability, and efficiency that makes it an invaluable component in industrial environments. Its proven track record, backed by numerous successful implementations and endorsements from industry professionals, attests to its value. As industries continue to prioritize safety and efficiency, serrated steel grating remains a pivotal choice for businesses committed to providing a secure and productive workplace.

One notable real-world application involves a large-scale manufacturing plant that experienced frequent slip-related incidents. By integrating serrated steel grating into key walkways and platforms, the plant significantly reduced workplace accidents, leading to a 15% increase in overall productivity. This case underscores how businesses can markedly improve operations by investing in quality materials designed with safety and efficiency in mind. For businesses considering serrated steel grating, several factors should be carefully evaluated. Material grade and load requirements are crucial factors that influence the selection process. Each application may demand specific load capacities, and choosing the right grade ensures that the grating withstands the rigors of its application environment. Professional consultation with engineers and suppliers can guide companies towards making informed decisions that align with their specific needs. Another critical factor is the installation process, which should be conducted by experienced professionals to ensure optimal performance. Proper installation not only maximizes the benefits of serrated grating but also prolongs its lifespan and enhances safety standards. Regular maintenance and inspection, though minimal, are recommended to ensure the grating continues to perform satisfactorily under operational stress. By choosing serrated steel grating, companies position themselves as leaders in safety innovation while reaping the operational benefits of reduced maintenance costs and increased efficiency. The investment in quality materials reflects a commitment to worker safety and operational excellence, further enhancing the company’s reputation within its industry. In conclusion, serrated steel grating offers a unique blend of safety, durability, and efficiency that makes it an invaluable component in industrial environments. Its proven track record, backed by numerous successful implementations and endorsements from industry professionals, attests to its value. As industries continue to prioritize safety and efficiency, serrated steel grating remains a pivotal choice for businesses committed to providing a secure and productive workplace.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024